Gas piston pulse engine

An engine and piston technology, applied in the field of gas piston pulse engines, can solve the problems of high manufacturing cost, complex structure, insufficient compression effect, etc., and achieve the effect of solving lubrication problems, less moving parts, and high compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

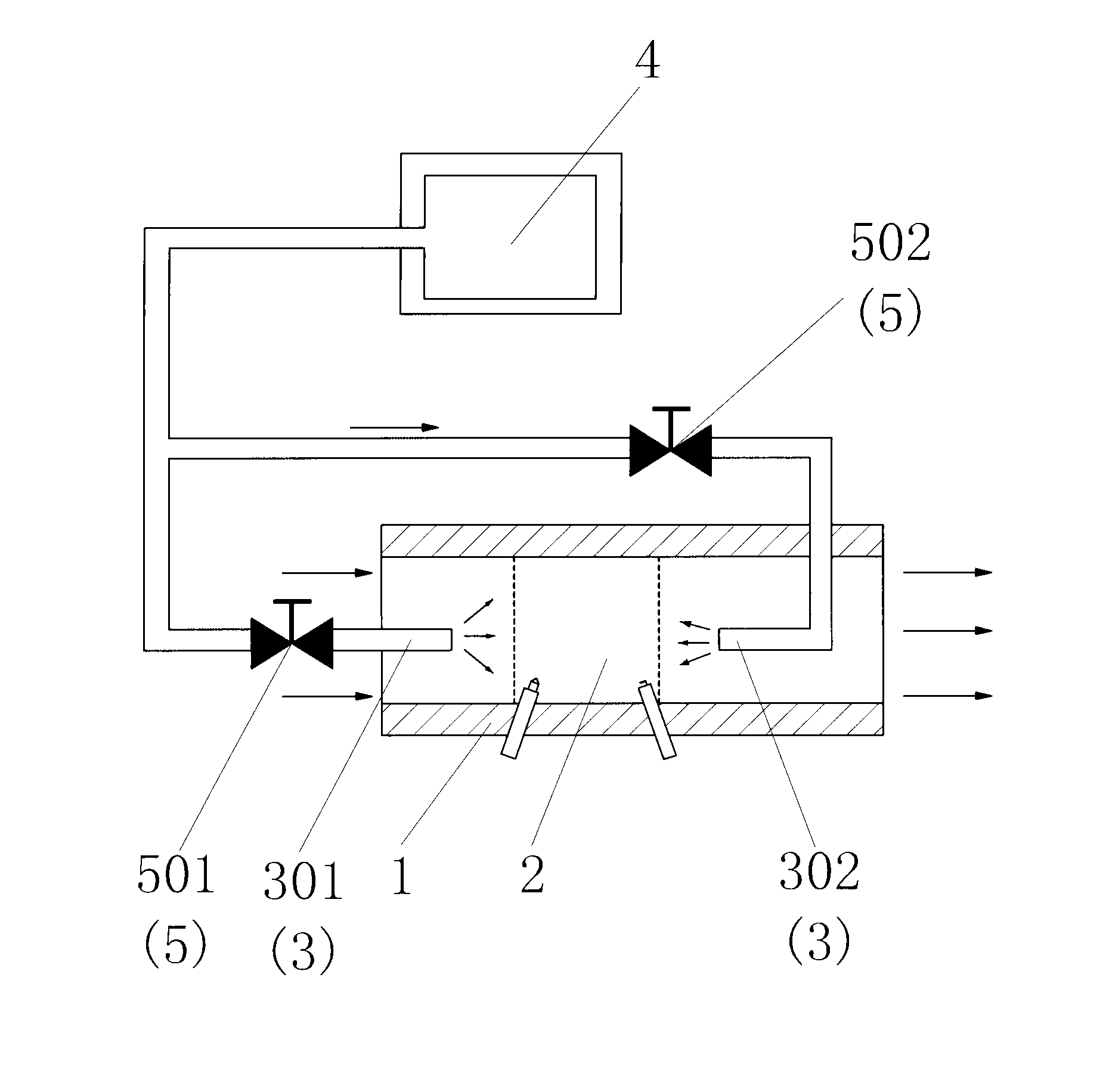

[0059] Such as figure 1 The gas piston pulse engine shown includes a nozzle 1, and a combustion chamber 2 is arranged in the nozzle 1; a forward high-pressure fluid nozzle 301 with the injection direction of the nozzle 1 as the overall injection direction is arranged in the nozzle 1, and the forward direction The high-pressure fluid nozzle 301 is arranged inside the cavity of the nozzle 1 on both sides of the combustion chamber 2, and the forward high-pressure fluid nozzle 301 communicates with the high-pressure fluid source 4 through the forward high-pressure fluid injection control valve 501; The opposite direction of the spraying direction of the nozzle 1 is the reverse high-pressure fluid nozzle 302 directed to the overall injection, and the reverse high-pressure fluid nozzle 302 is arranged inside the cavity of the nozzle 1 on both sides of the combustion chamber 2 . The reverse high-pressure fluid nozzle 302 communicates with the high-pressure fluid source 4 through the ...

Embodiment 2

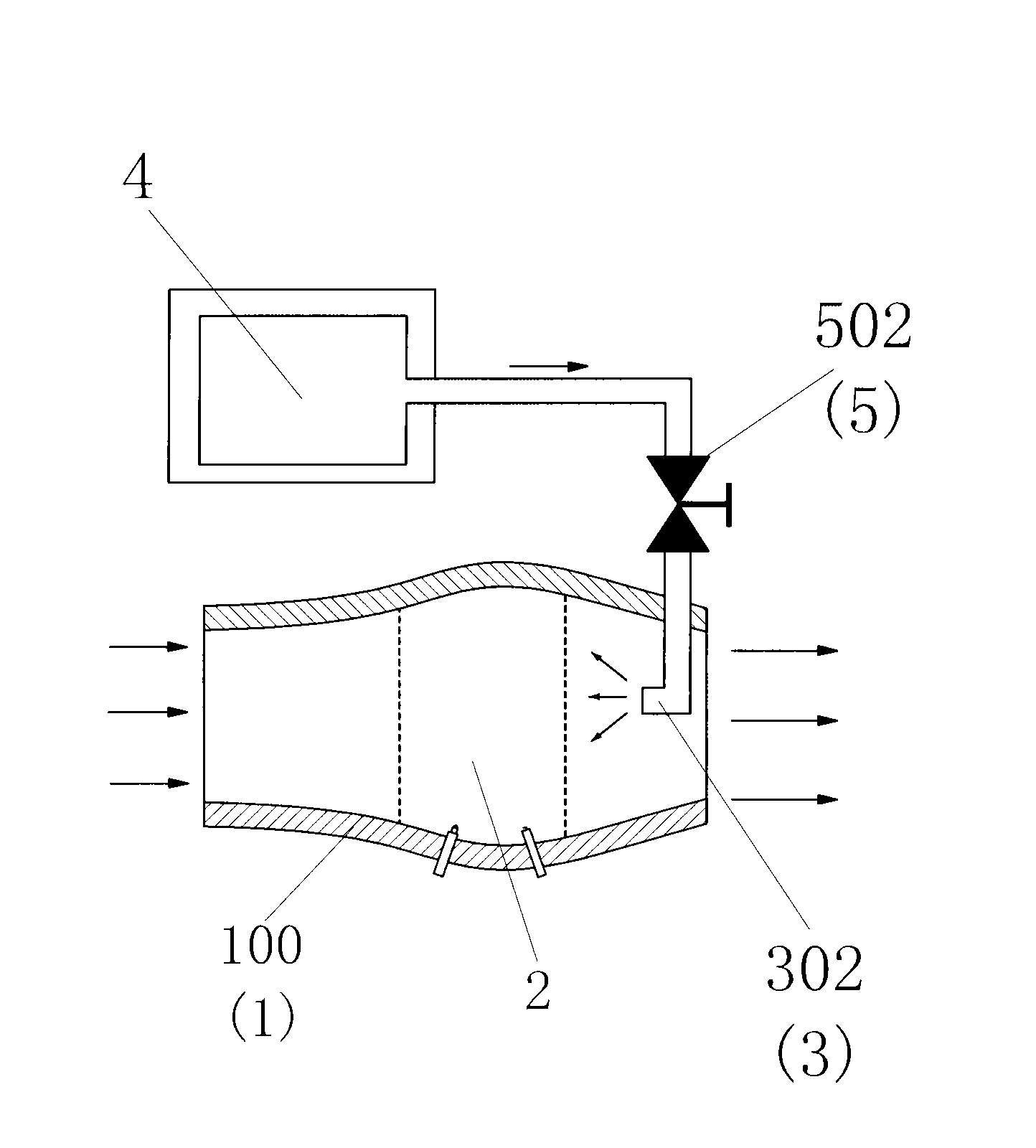

[0061] Such as figure 2 The gas piston pulse engine shown differs from Embodiment 1 in that only the reverse high-pressure fluid nozzle 302 with the reverse direction of the injection direction of the nozzle 1 as the overall injection direction is set in the nozzle pipe 1, and the reverse high-pressure fluid nozzle 302 It communicates with the high-pressure fluid source 4 through the reverse high-pressure fluid injection control valve 502 . High-pressure fluid nozzles 3 are arranged on the side walls of the nozzle pipe 1 on both sides of the combustion chamber 2 . The nozzle pipe 1 is designed as a partially pressurized nozzle pipe 100 with an expansion zone.

Embodiment 3

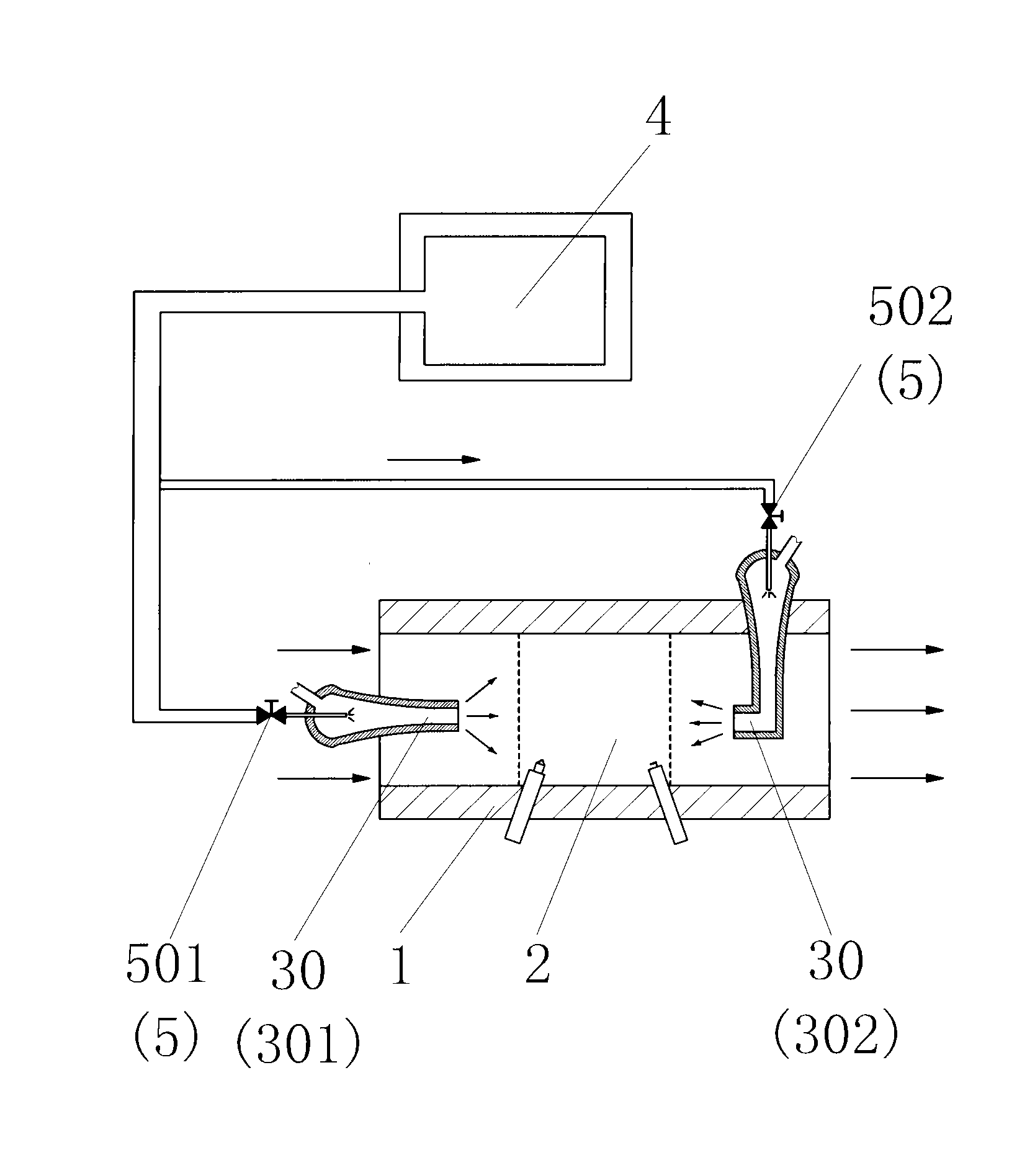

[0063] Such as image 3 The gas piston pulse engine shown differs from Embodiment 1 in that: the forward high-pressure fluid nozzle 301 and the reverse high-pressure fluid nozzle 302 are all set as the Venturi jet tube nozzle 30, and the high-pressure gas of the Venturi jet tube nozzle 30 The inlet communicates with a high-pressure fluid source 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com