Method and device for detecting wall of cylindrical transparent bottle

A detection device and cylinder technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unconstant standards, fuzzy manual detection standards, large camera space, etc., to eliminate unclean bottles The use, testing standards are stable and reliable, and the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

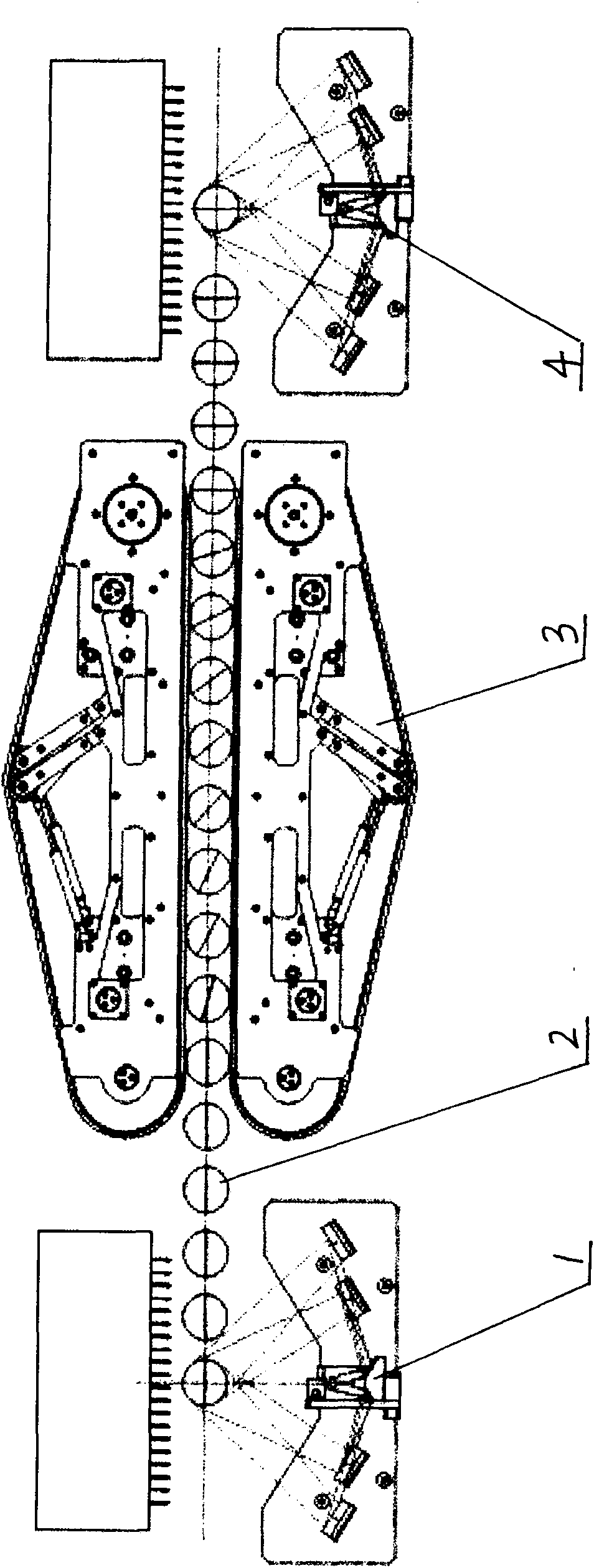

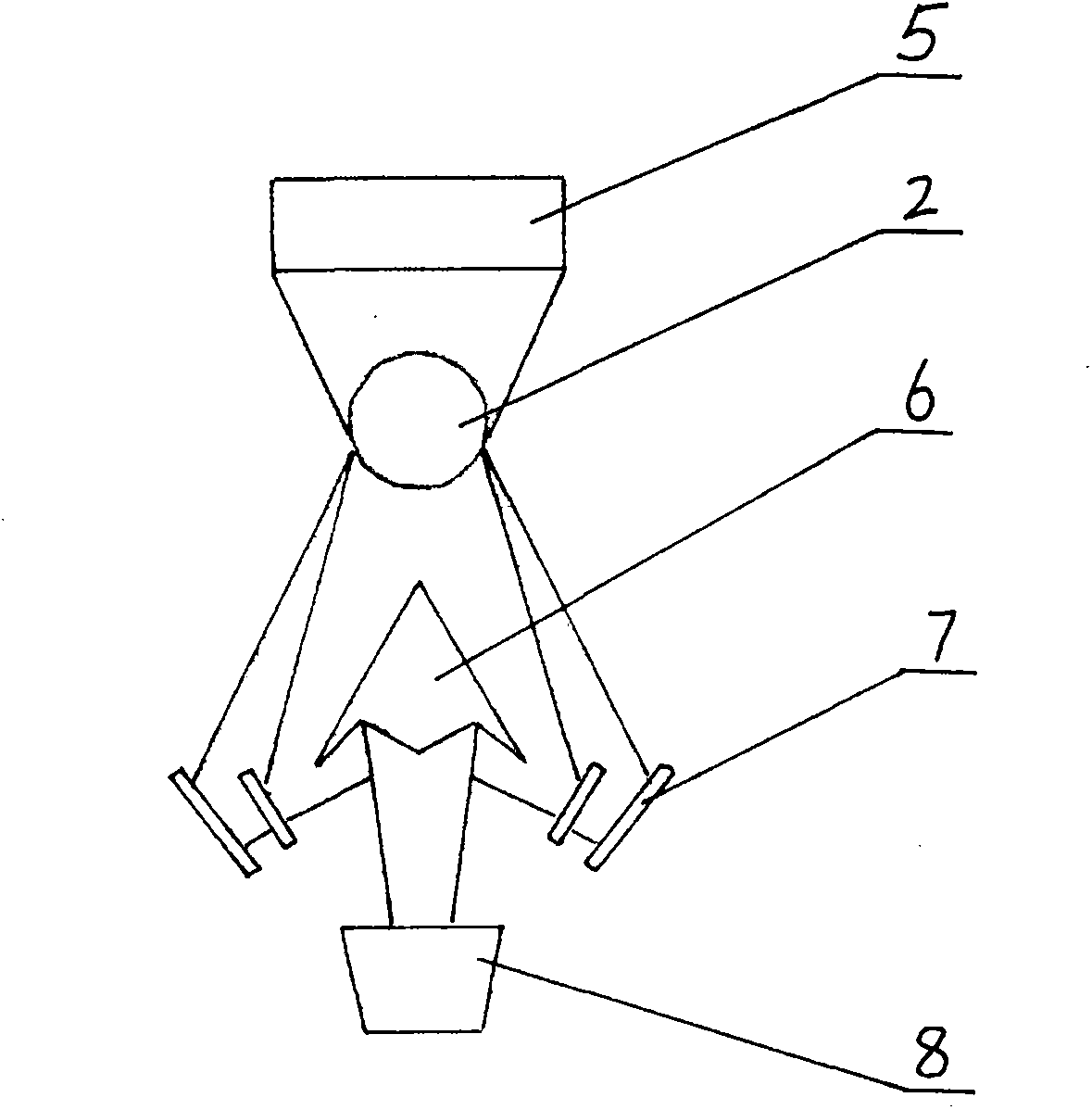

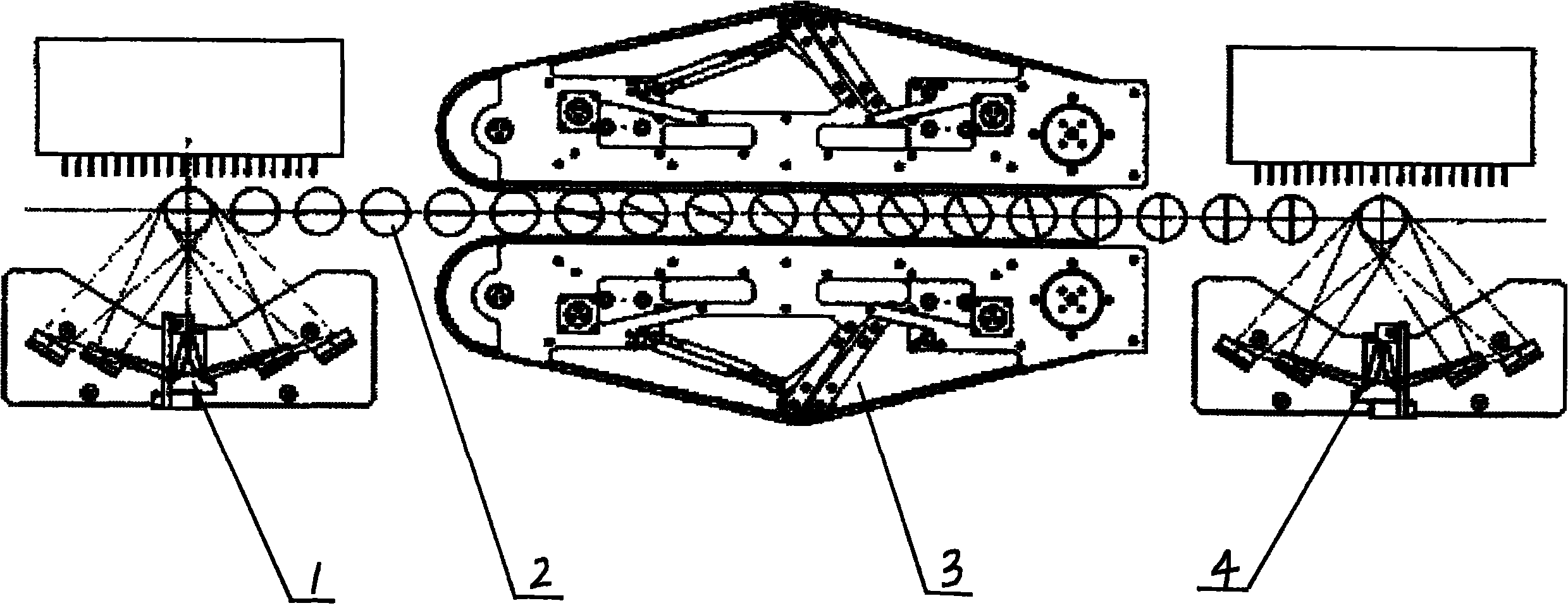

[0011] The device of the invention comprises a frame, a bottle conveying track, a bottle rejecting device, a power device, an image acquisition device, an image processing device, a motion control system and an industrial computer. From figure 1 As can be seen from the schematic diagram of the image acquisition device of the present invention shown, the image acquisition device comprises an inlet bottle wall detection device 1 and an outlet bottle wall detection device 4, and a speed difference is set between the inlet bottle wall detection device 1 and the outlet bottle wall detection device 4 The conveying mechanism 3, the inlet bottle wall detection device 1 and the outlet bottle wall detection device 4 respectively include a camera, a mirror and a stroboscopic light source, and the camera is connected with an image processing device, a motion control system, an industrial computer and a bottle rejecting device. In the bottle wall inspection, the strobe LED light source is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com