Preparation method of vitrification substrate for radioactive nuclear waste

A technology of radioactive nuclear and vitrification, which is applied in the preparation of radioactive nuclear waste vitrified substrates, and in the field of solidification treatment of radioactive nuclear waste. It can solve the problems of poor radiation stability and thermal stability, easy performance of cured products, and practical application limitations. and other problems, to achieve the effect of good thermal stability, excellent chemical stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

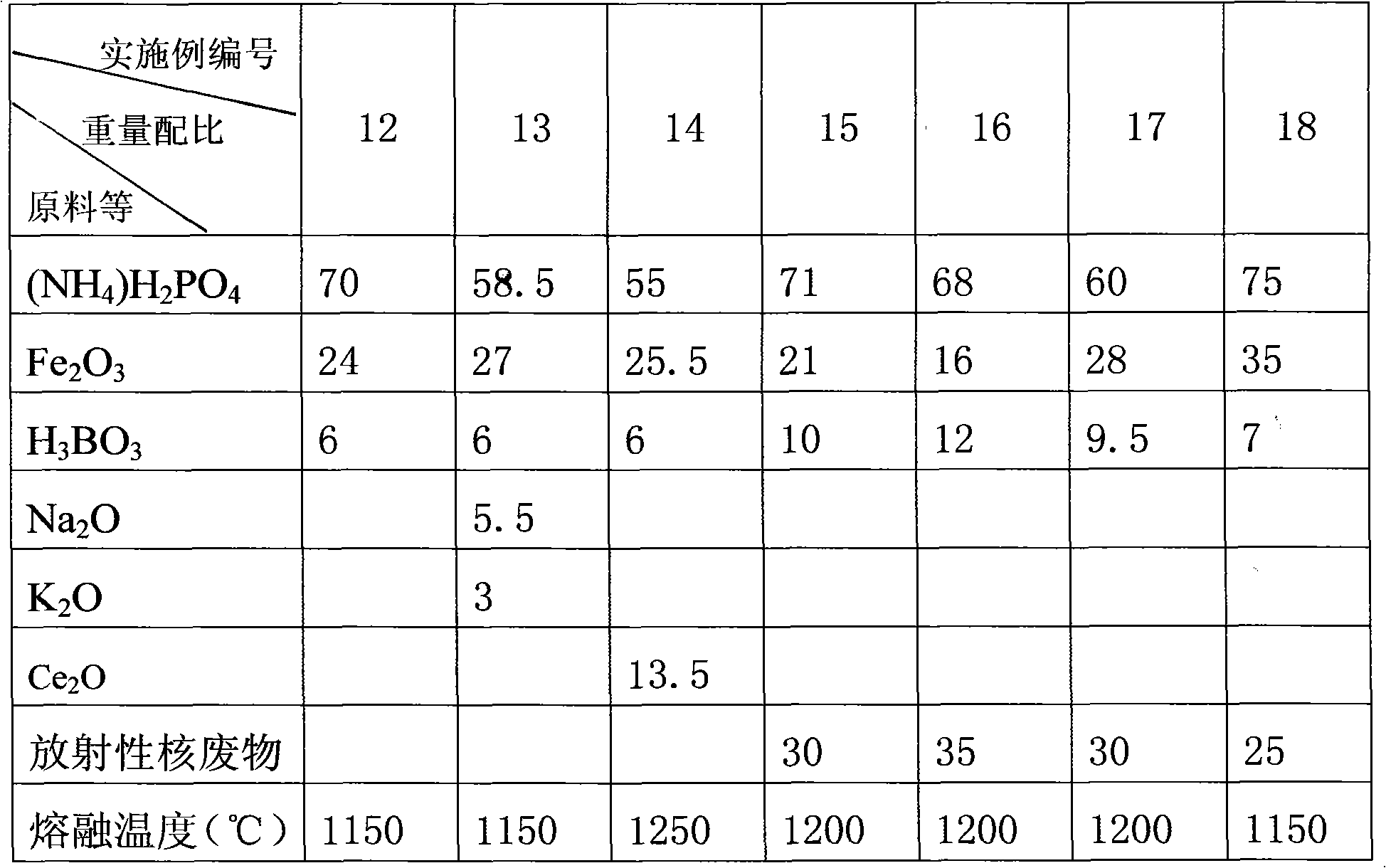

Examples

Embodiment 1

[0027] A preparation method for radioactive nuclear waste vitrified base material, comprising the following steps:

[0028] a. Ingredients: by component (NH 4 )H 2 PO 4 , Fe 2 o 3 、H 3 BO 3 as raw material, and according to (NH 4 )H 2 PO 4 64g, Fe 2 o 3 30g, H 3 BO 3 The ratio of 6.5g is taken from each raw material;

[0029] b. Mixing: Put all the raw materials into the mixing equipment (mortar or ball milling equipment) and fully mix them evenly to make a mixed material;

[0030] c. Melting: heating and melting the mixed material at a temperature of 1150°C for 2.5 to 3 hours to obtain a melt;

[0031] d. Forming: pour the melt into a steel mold preheated to 850°C to form a molded product;

[0032]e. Annealing: heat the molding at 450°C for 1 hour, and then lower the temperature to room temperature at a rate of 1°C / min to obtain the product—cured base glass.

Embodiment 2

[0034] A preparation method for radioactive nuclear waste vitrified base material, comprising the following steps:

[0035] a. Ingredients: by component (NH 4 )H 2 PO 4 , Fe 2 o 3 、H 3 BO 3 、Na 2 O is the raw material, and press (NH 4 )H 2 PO 4 56g, Fe 2 o 3 26g, H 3 BO 3 6g, Na 2 The ratio of 012g gets each raw material;

[0036] b. Mixing: put each raw material into mixing equipment (mortar or ball milling equipment) and mix evenly to make a mixed material;

[0037] c. Melting: heating and melting the mixed material at a temperature of 1150°C for 2.5 to 3 hours to obtain a melt;

[0038] d. Forming: pour the melt into a steel mold preheated to 800°C to form a molded product;

[0039] e. Annealing: heat the molding at 450°C for 1 hour, and then lower the temperature to room temperature at a rate of 1°C / min to obtain the product—cured base glass.

Embodiment 3

[0041] A preparation method for radioactive nuclear waste vitrified base material, comprising the following steps:

[0042] a. Ingredients: by component (NH 4 )H 2 PO 4 , Fe 2 o 3 、H 3 BO 3 , radioactive nuclear waste as raw materials, and press (NH 4 )H 2 PO 4 74g, Fe 2 o 3 17g, H 3 BO 3 13g, 30g of radioactive nuclear waste to take each raw material;

[0043] b. Mixing: put each raw material into mixing equipment (mortar or ball milling equipment) and mix evenly to make a mixed material;

[0044] c. Melting: heating and melting the mixed material at a temperature of 1200°C for 2.5 to 3 hours to obtain a melt;

[0045] d. Forming: pour the melt into a steel mold preheated to 800°C to form a molded product;

[0046] e. Annealing: heat the molded product at a temperature of 450°C for 1 hour, and then lower the temperature to room temperature at a rate of 1°C / min to obtain a cured product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com