Components and manufacturing process of rare earth permanent magnet material

A rare earth permanent magnet, manufacturing process technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of large investment, rising, low profit of low-end products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0038] According to the following atomic percentage

[0039] (Pr, Nd) 13.35 Dy 0.1 B 5.85 Nb 0.15 al 0.1 Fe 其余

[0040] (Pr, Nd) 13.2 Dy 0.25 B 5.85 al 0.1 Fe 其余

[0041] Preparation of raw materials, in which Pr and Nd are added in the form of alloys, the content of Pr is about 20%, the average particle size of jet mill powder is 3.0um, and it is oriented in a 1.9T magnetic field, and the rough density is 4.2g / cm 3 , and then sintered in a vacuum sintering furnace at a temperature of 1055°C and a holding time of 4hrs, and then carry out secondary aging: the first aging temperature is 900°C and holding time is 2 hours; the secondary temperature is 470°C and holding time is 3 hours. Released for performance testing.

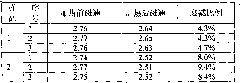

[0042]

[0043] The oxygen content of the two samples is 800-1000PPM. From the comparison, it can be seen that the Hcj is basically the same, but because the Nb-added formula uses less Dy, the formula cost is low; and the Nb-added product ha...

Embodiment example 2

[0045] According to the following atomic percentage

[0046] (Pr, Nd) 10.65 Dy 2.85 B 6 Nb0.3 al 0.5 co 2 Cu 0.2 Fe 其余

[0047] (Pr, Nd) 10.4 Dy 3.1 B 6 al 0.5 co 2 Cu 0.2 Fe 其余

[0048] Preparation of raw materials, in which Pr and Nd are added in the form of alloys, the content of Pr is about 20%, the average particle size of jet mill powder is 3.0um, and it is oriented in a 1.9T magnetic field, and the rough density is 4.2g / cm 3 , and then sintered in a vacuum sintering furnace at a temperature of 1075°C and a holding time of 4hrs, and then carry out secondary aging: the first aging temperature is 910°C, holding for 2 hours, the secondary temperature is 500°C, holding for 3 hours, and cooling after the holding Released for performance testing.

[0049]

[0050] The oxygen content of the two samples is 1000-1500PPM. From the comparison, it can be seen that the Hcj is almost the same. The dosage of Dy in the formula with Nb added is much less and the...

Embodiment example 3

[0052] According to the following atomic percentage

[0053] (Pr, Nd) 12.6 Dy 0.7 Tb 0.1 B 6 Nb 0.2 al 0.3 co 0.5 Fe 其余

[0054] (Pr, Nd) 12.5 Dy 0.6 Tb 0.3 B 6 al 0.3 co 0.5 Fe 其余

[0055] Preparation of raw materials, in which Pr and Nd have been added in the form of alloys, the content of Pr is about 20%, the average particle size of jet mill powder is 3.0um, and it is oriented in a 1.9T magnetic field, and the rough density is 4.2g / cm 3 , and then sintered in a vacuum sintering furnace at a temperature of 1070°C and a holding time of 4hrs, and then carry out secondary aging: the first aging temperature is 900°C, holding for 2 hours, the secondary temperature is 480°C, holding for 3 hours, and cooling after the holding Released for performance testing.

[0056]

molecular formula

Br / kg

the s

Hcj / kOe

Hk / kO

e

(BM)max

1

(Pr, Nd) 12.6 Dy 0.7 Tb 0.1 B 6 Nb 0.2 al 0.3

co 0.5 Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com