Process and system for preparing ammonia from ammonium bicarbonate by using wet process for flue gas denitration

A technology of ammonium bicarbonate and ammonium bicarbonate solution, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem of uneven feeding amount of ammonium bicarbonate, poor system operation stability, and easy fluctuation of ammonia gas volume. and other problems, to achieve the effect of easy control of the ammonia production process, prevention of crystallization in the tube, convenient and safe transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

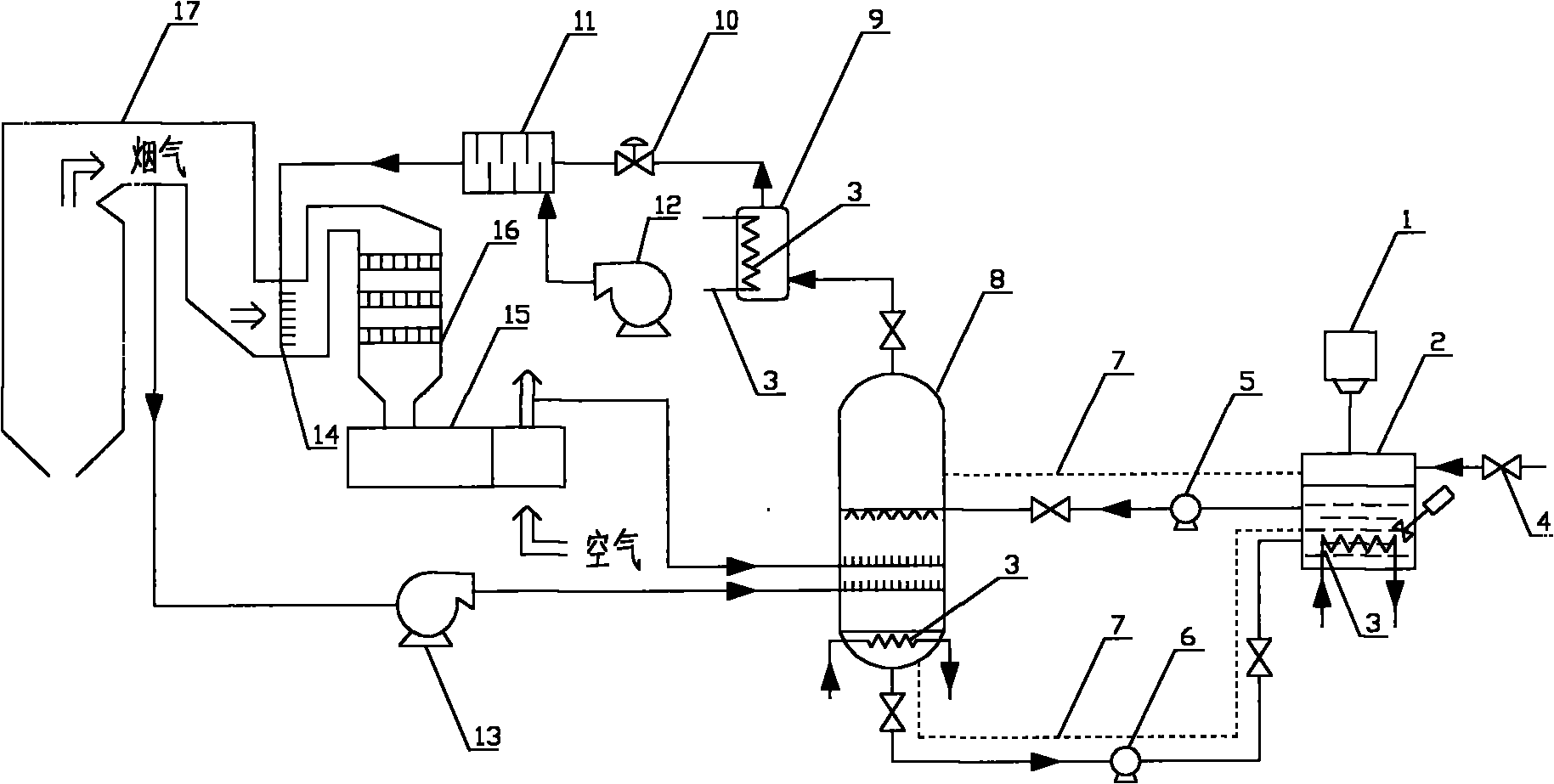

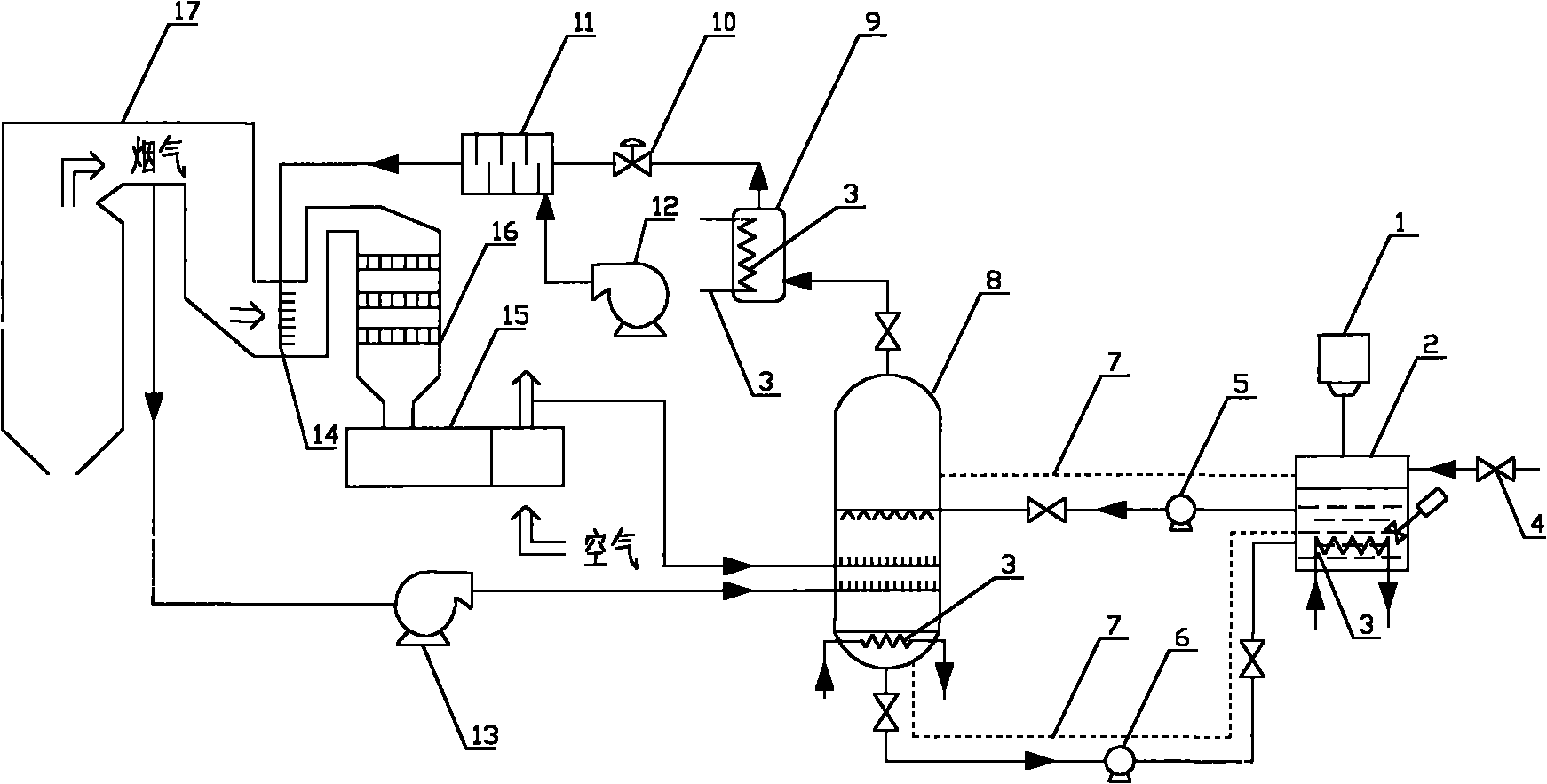

[0038] The present invention provides an ammonium bicarbonate wet ammonia production process for flue gas denitrification, and the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

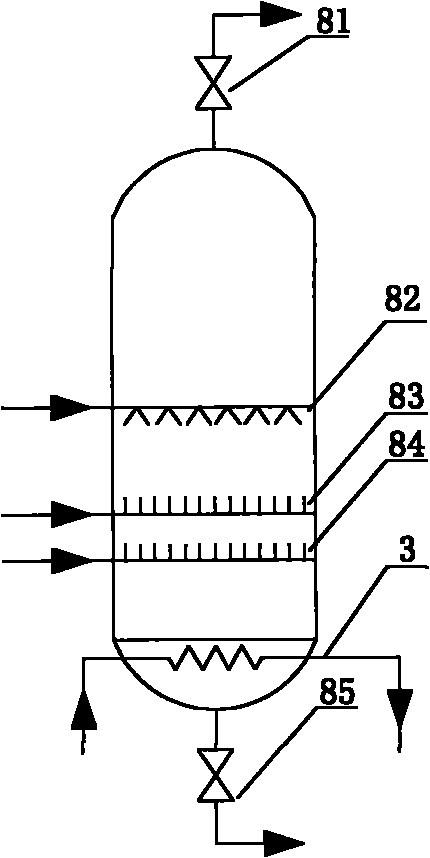

[0039] likefigure 1 As shown, the pyrolysis chamber 8 is a vertical round tank, the atomizing injection pipe 82 is arranged at the 3 / 5 elevation of the pyrolysis chamber, the high-temperature air introduction pipe 83 is arranged at the 1 / 3 elevation of the pyrolysis chamber, and the high-temperature flue gas The introduction pipe 84 is arranged at 1 / 4 elevation of the pyrolysis chamber. The outlet of the dissolution tank 2 is connected to the atomization injection pipe 82 at the upper part of the pyrolysis chamber 8 through a pipeline and a booster pump 5, and the high-temperature flue gas outlet of the boiler 17 is connected to the high-temperature flue gas at the lower part of the pyrolysis chamber 8 through a pipeline and a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com