Saw plate positioning device for gang saw welder

A positioning device and welding machine technology, applied in the field of machinery, can solve the problems of inaccurate welding saw teeth, reduce production efficiency, increase spacing, etc., and achieve the effects of ensuring accuracy and pressing force, improving stability, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

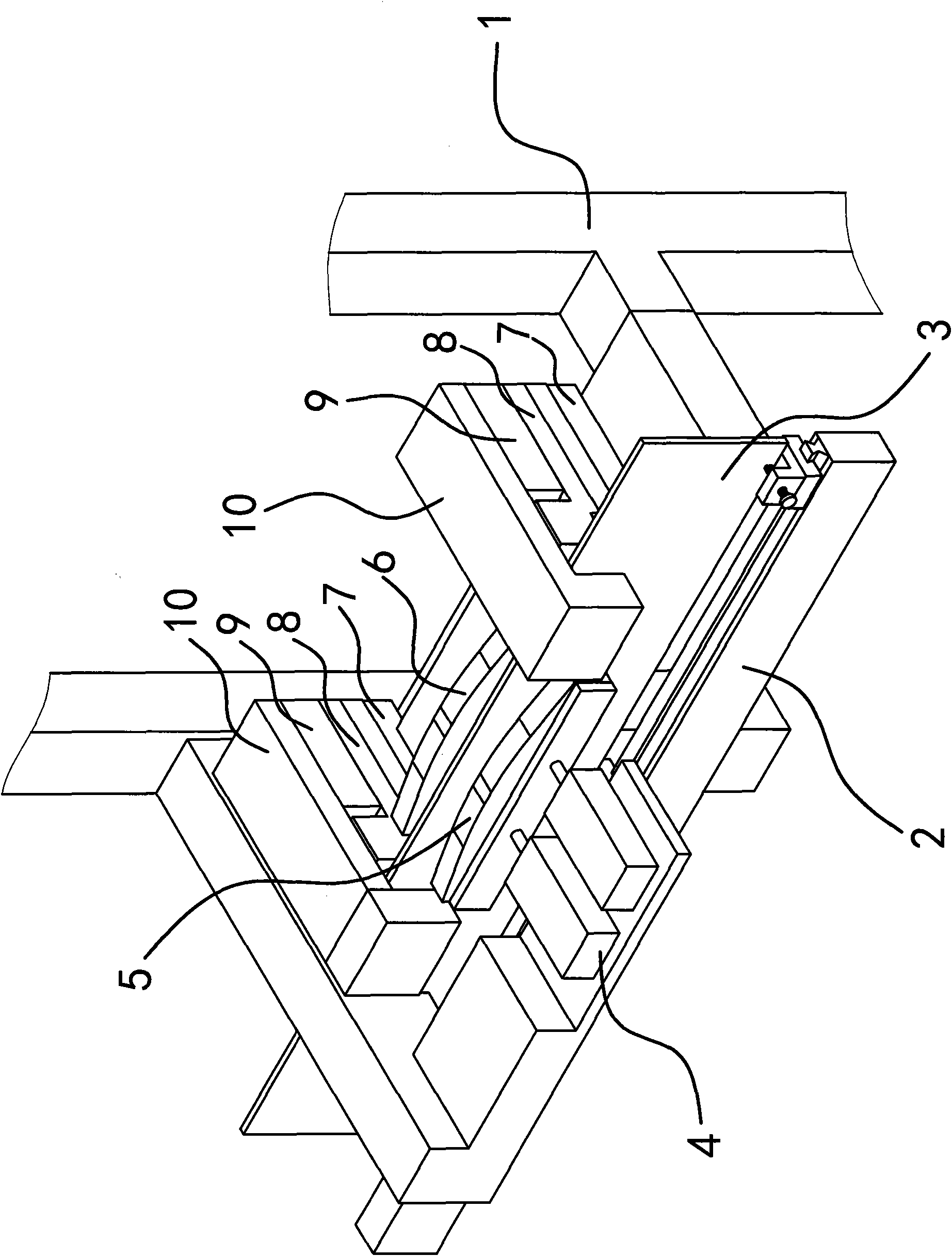

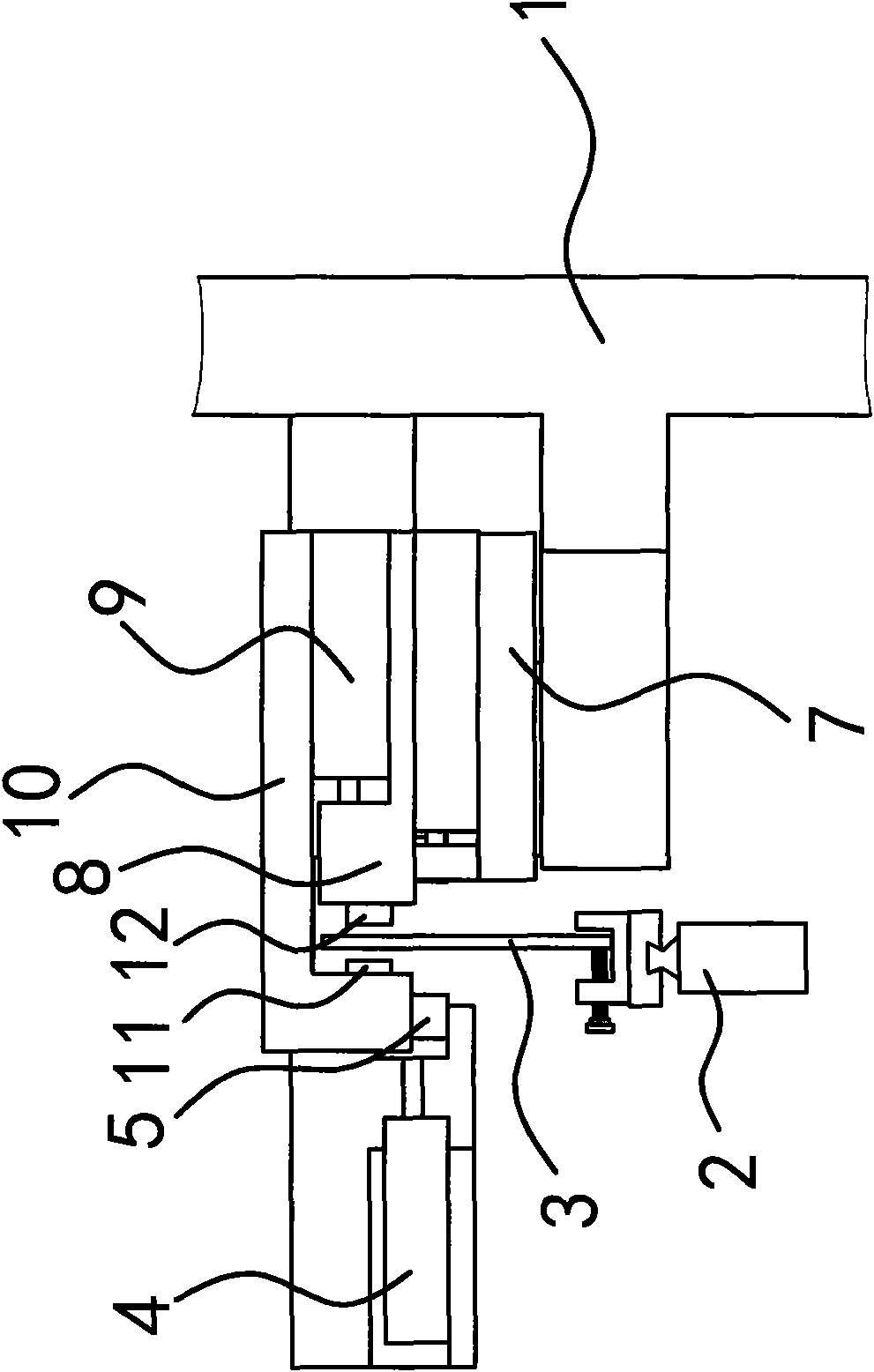

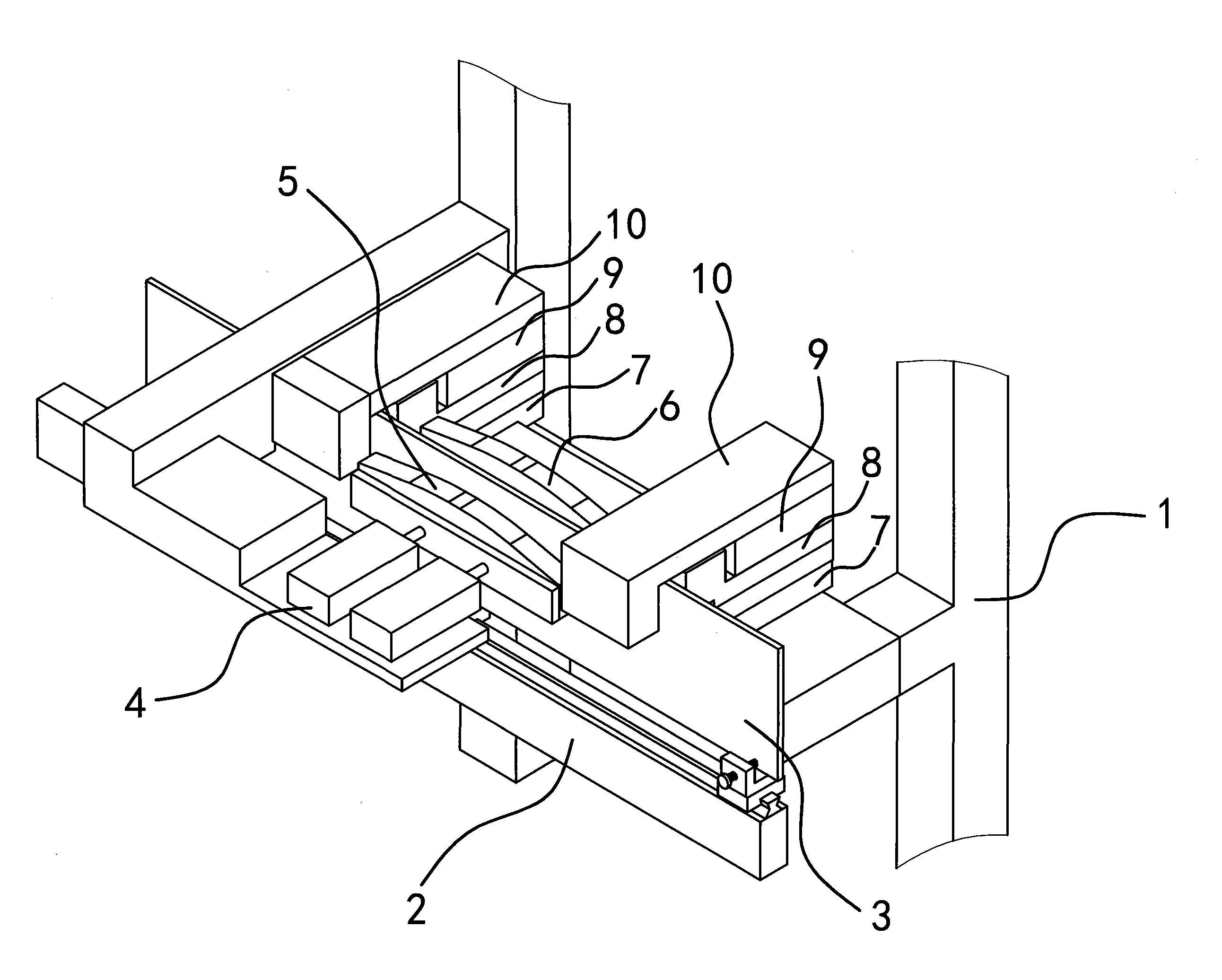

[0028] Specifically, as figure 1 and figure 2 As shown, the clamping block one 6 is fixed on the frame 1 and is positioned at the inner side of the saw board 3, the clamping block two 5 and the cylinder one 4 are arranged on the outside of the saw board 3, and the cylinder body of the cylinder one 4 is fixed on the frame 1, the clamping block two 5 is fixed on the piston rod of the cylinder one 4. The pressing surface of the clamping block one 6 is opposite to the pressing surface of the clamping block. The saw board 3 is located between the clamping block one 6 and the clamping block two 5. Clamping block two 5 moves towards the direction close to clamping block one 6, and sawing board 3 is clamped and fixed under the joint action of clamping block one 6 and clamping block two 5.

[0029] Guide piece one 11 and guide piece two 12 are guide rollers, and this guide roller directly replaces with bearing. Both sides of the clamping block 6 are provided with a guide 11; the el...

Embodiment 2

[0040] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the elastic mechanism includes a guide rod 1 and a fixed seat 8, the guide rod 1 is fixed on the frame 1, and the fixed seat 8 is slidably connected to the guide rod 1. On the rod one, the above-mentioned guide part one 11 is arranged on the fixed seat one 8, and a guide bar is provided between the guide rod one and the fixed seat one 8 so that the guiding surface of the guide part one 11 to the guide part one 11 is always close to the clamping block two. Move spring one in the direction of the pressing surface of 5. The cylinder block of cylinder three 9 is fixed on the holder one 8 in the driving mechanism.

Embodiment 3

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the drive mechanism includes guide rod two, fixed seat two 10, the guide rod two is fixed on the fixed seat one 8, and the fixed seat two 10 is slidably connected to the guide On the rod two, the above-mentioned guide member two 12 is arranged on the second fixing seat 10, and a spring two is arranged between the second guide rod and the second fixing seat 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com