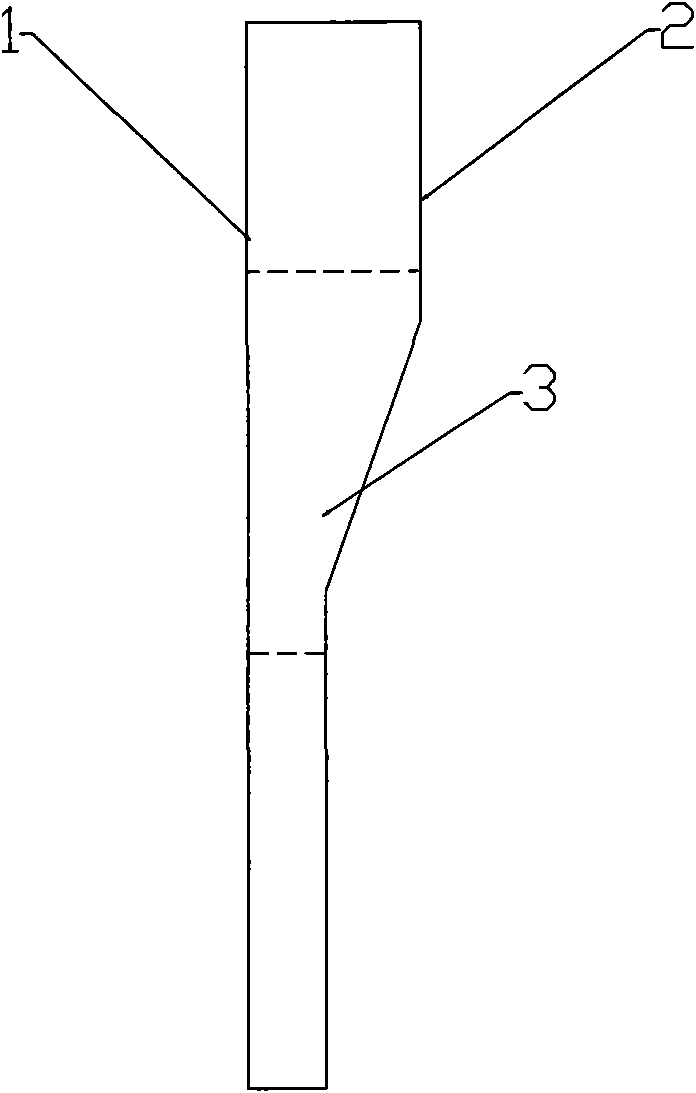

Method for machining encircling hole with meridian plane group nozzle

A hole processing method and nozzle group technology, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as the impossibility of milling processing of girdle-shaped holes, improve the production level, improve work efficiency, Effects that are easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

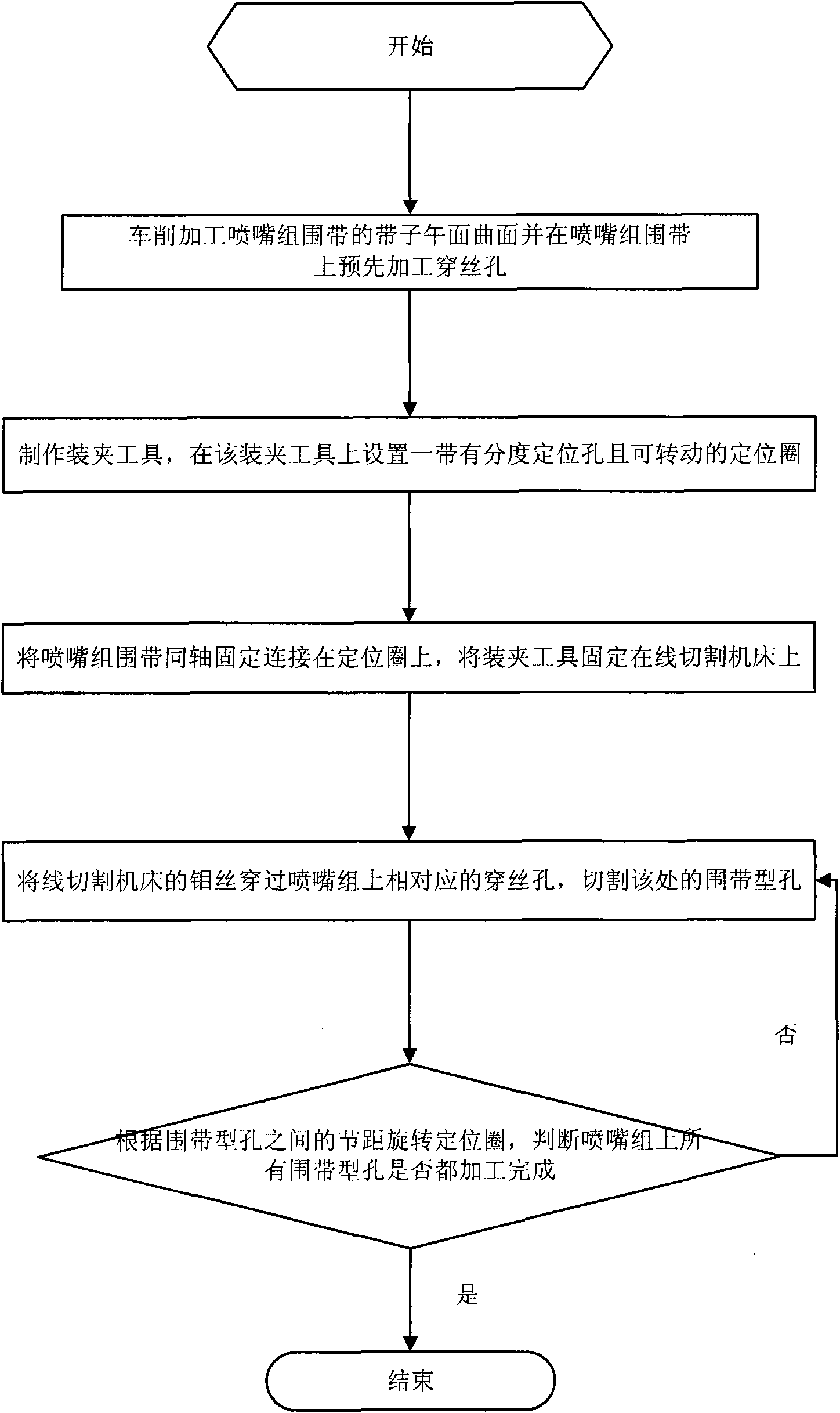

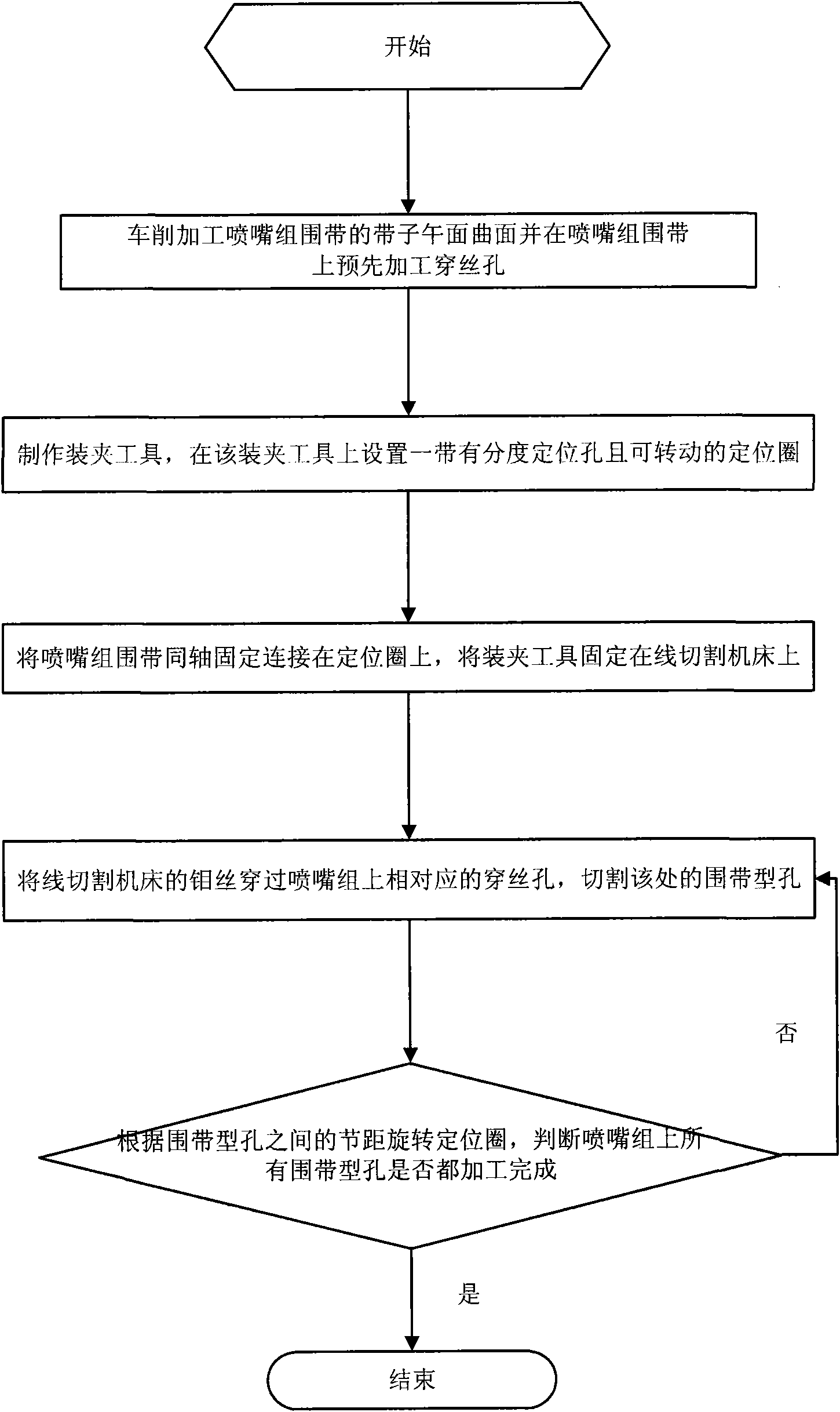

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] like figure 2 Shown, this belt meridian surface nozzle group shroud type hole processing method, it comprises the following steps:

[0019] (a) The curved surface with meridian surface on the surrounding belt of the nozzle group is processed by CNC machine tool turning, and the curved surface with meridian surface on the surrounding belt of the nozzle group needs to be subjected to one rough machining, one finishing machining and one stress relief treatment respectively. The function is to prevent the processing deformation of the thin-walled whole ring parts. During the turning process, the turning chuck end should be given a sufficient margin. After all the machining dimensions such as the curved surfaces and inclinations are accurately turned, the width of the entire ring must be cut accurately. , which can ensure the machining ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com