Method for improving electric conductivity of carbon nano tube network

A technology of carbon nanotubes and conductivity, which is applied in the field of improving the conductivity of carbon nanotube networks, can solve problems affecting the conductivity of carbon nanotube fibers, etc., and achieve the effect of improving conductivity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Specifically, proceed through the following steps:

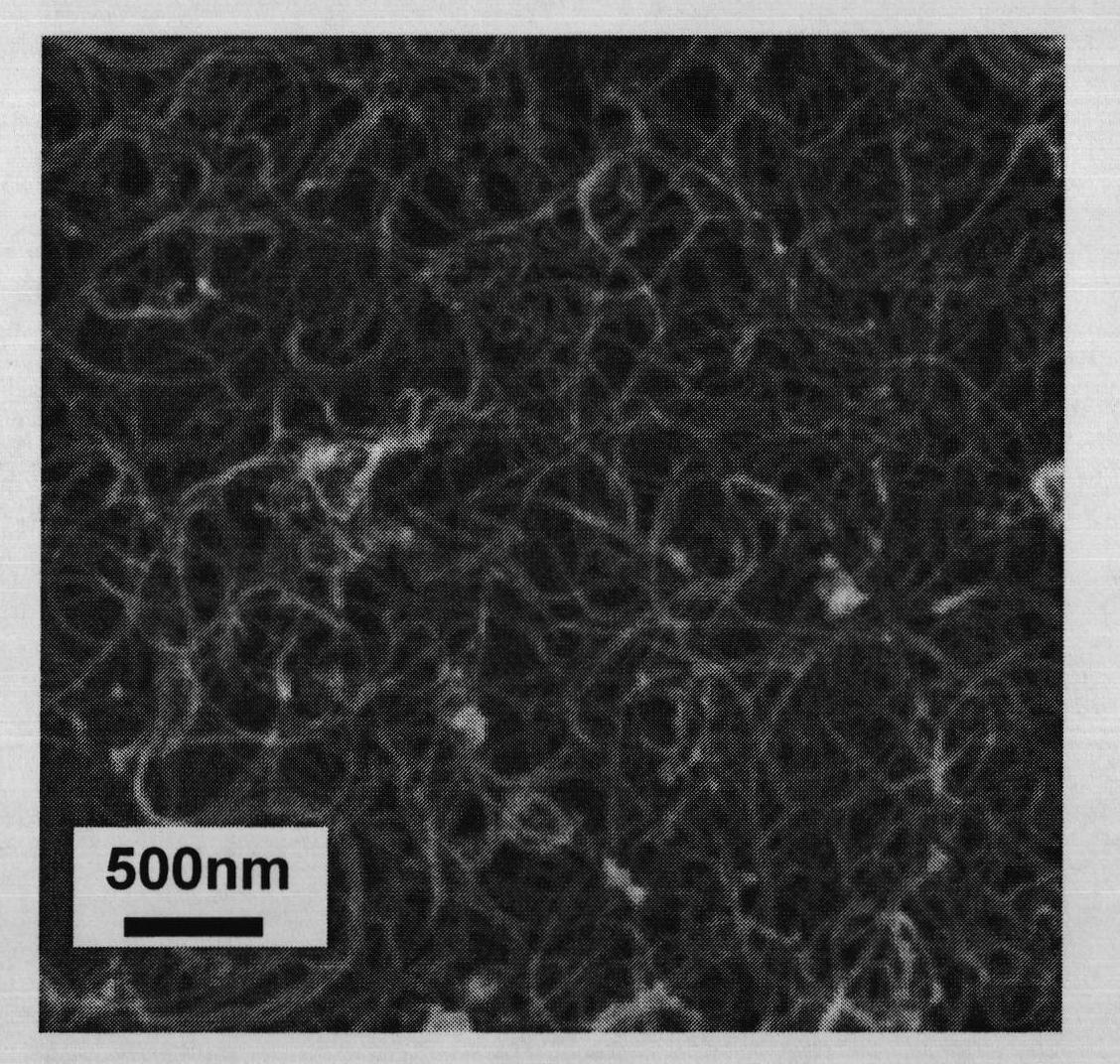

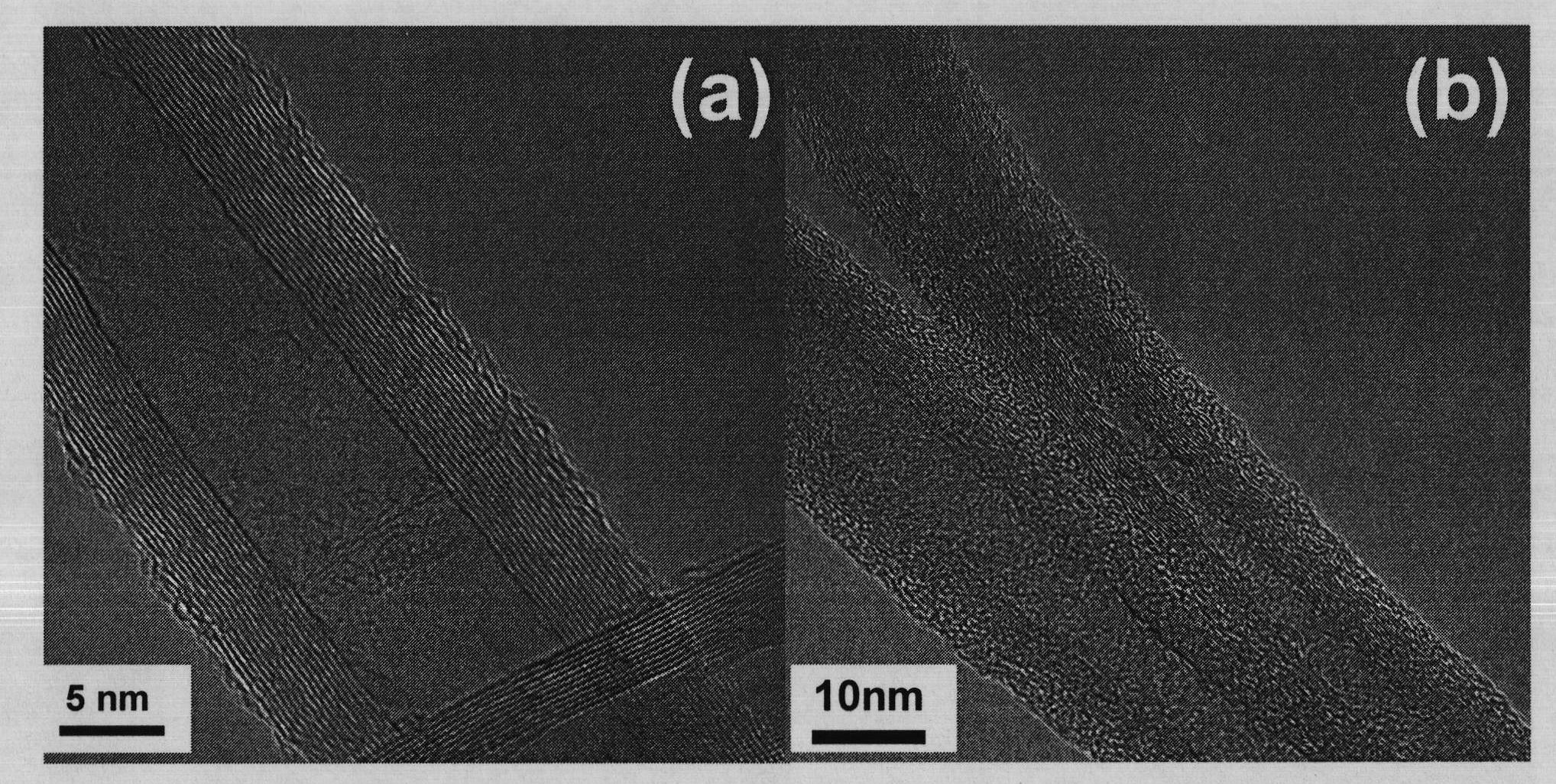

[0023] 1) Carbon nanotube sample preparation: carbon nanotube powder was put into ethanol solvent to prepare a suspension, and the water area was sonicated for 3 hours. The substrate is a flat, cleaned quartz plate of 20mm×20mm×1mm. The substrate is placed on a heating stage with a temperature of 150°C, covered with a 0.3mm thick mask to control the shape and size of the sample, and placed for 10 minute. Use a pneumatic airbrush to spray the prepared carbon nanotube suspension onto the heated substrate in the form of a spray with the assistance of nitrogen, and control the spraying time so that the transmittance of the resulting carbon nanotube network at 550nm visible light is 88%. %. Replace the substrate with a conductive silicon wafer, repeat the above preparation process, so that the carbon nanotube network on the silicon wafer is the same as that on the quartz substrate, observe the sample on the silicon wafer...

Embodiment 2

[0029] Specifically, proceed through the following steps:

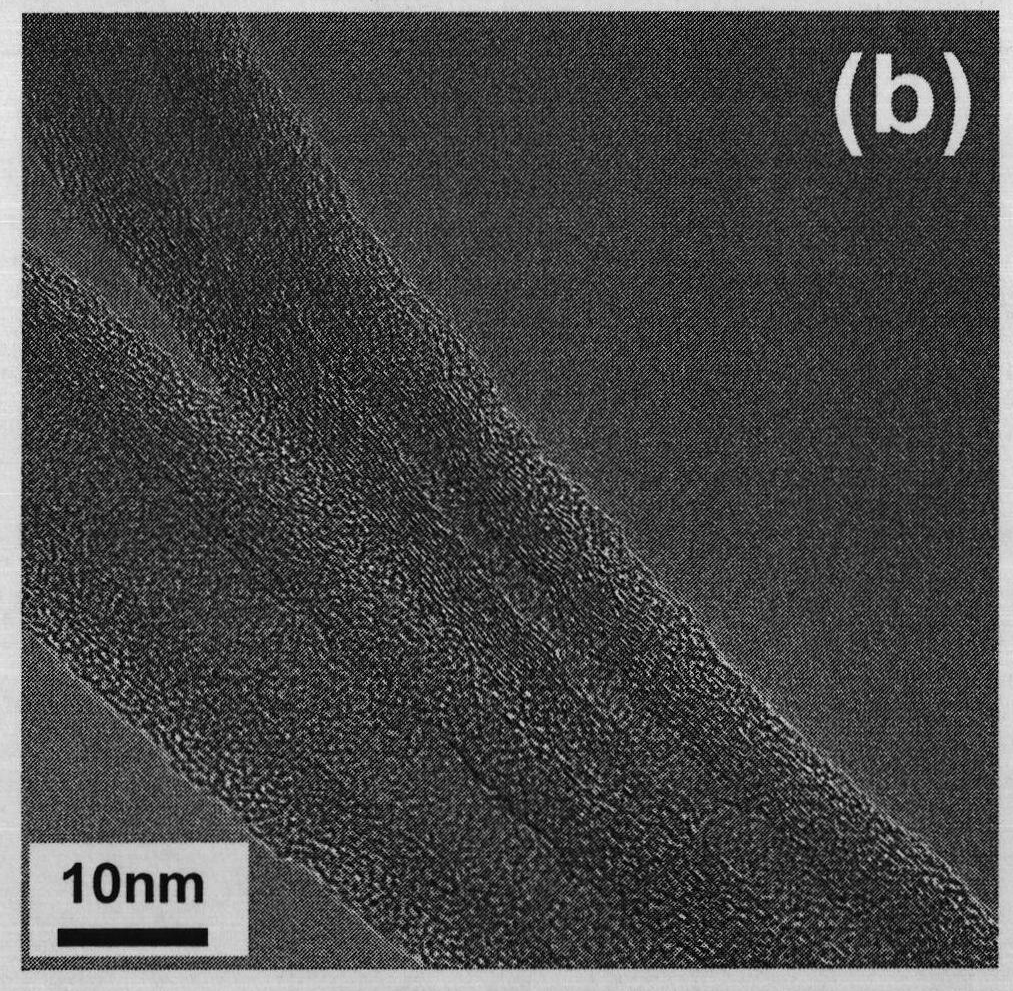

[0030] 1) Carbon nanotube sample preparation: carbon nanotube powder was put into ethanol solvent to prepare a suspension, and the water area was sonicated for 3 hours. The substrate is a flat, cleaned quartz plate of 20mm×20mm×1mm. The substrate is placed on a heating stage with a temperature of 150°C, covered with a 0.3mm thick mask to control the shape and size of the sample, and placed for 10 minute. Use a pneumatic airbrush to spray the prepared carbon nanotube suspension onto the heated substrate in the form of a spray with the assistance of nitrogen, and control the spraying time so that the transmittance of the resulting carbon nanotube network at 550nm visible light is 63%. %.

[0031] 2) Place the sample on the quartz substrate in a vacuum (vacuum degree 10 -4 Pa) was heated to 800K, kept for at least 30 minutes, and then naturally cooled to room temperature in vacuum. The conductivity of the network was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com