Biodegradable mulching film

A technology of biodegradation and mulching, which is applied to plant protection covers, climate change adaptation, etc., can solve problems such as water resistance and hydrophilicity, residual particles or fragments, and incomplete degradation, etc., and achieve water resistance and hydrophilicity The problem of sexual balance, the effect of uniform and thorough degradation, and low comprehensive use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the concrete implementation of a kind of biodegradable mulch film of the present invention, can adopt above-mentioned component to carry out the production of mulch film, the source of its raw material can be:

[0028] The alloy masterbatch is produced by Changzhou Bailiji Biomaterials Technology Co., Ltd.;

[0029] 7042 (LDPE) adopts the product produced by Guangdong Maoming Petrochemical Company;

[0030] 1F7B (LDPE) adopts the product produced by Beijing Yanshan Petrochemical Company.

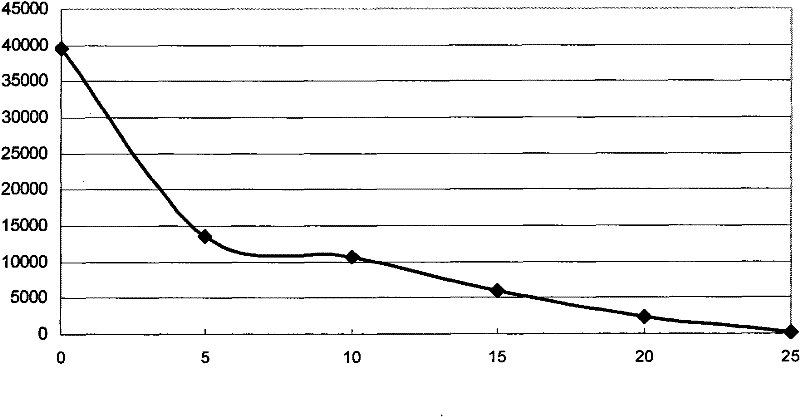

[0031] The National Synthetic Resin and Plastic Quality Supervision and Inspection Center submitted a sample for inspection of a biodegradable mulch film of the present invention at an ultraviolet irradiation temperature of 63°C and an intensity of 1000uW / C m 2 The degradation effect was tested under the conditions. The results of the test are shown in the table below, and the graphs made according to it are shown in the accompanying drawings:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com