Epoxy resin composition for packaging semiconductors

A technology of epoxy resin and composition, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of reduced reliability of semiconductor devices, and achieve the effect of excellent flame retardancy and moisture-heat reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

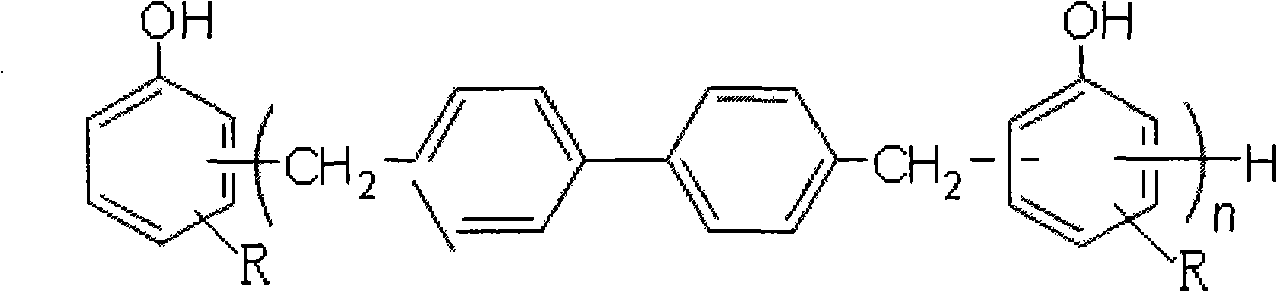

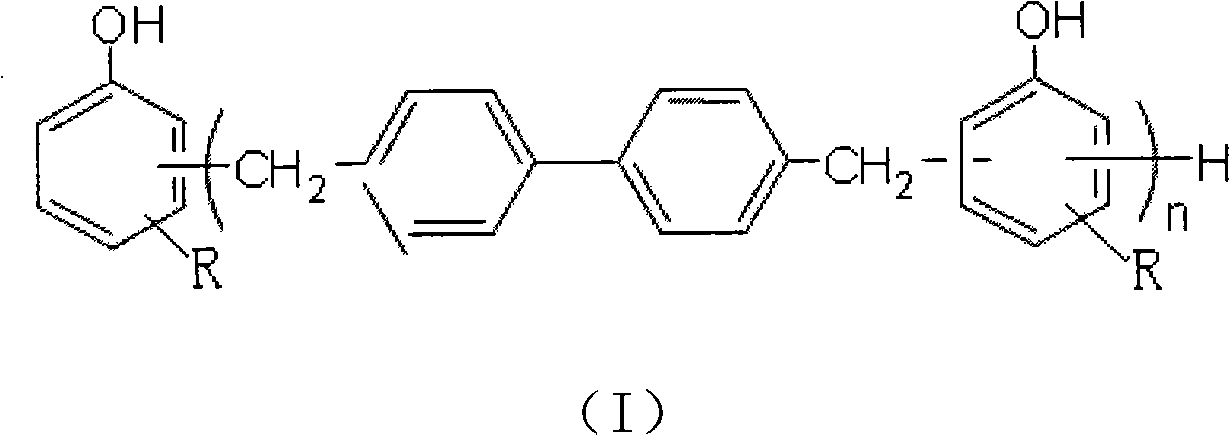

[0018] Example 1. An epoxy resin composition for semiconductor encapsulation, the composition comprises: epoxy resin, phenolic resin curing agent, curing accelerator, inorganic filler; described phenolic resin curing agent refers to containing following general formula (I) The phenolic resin:

[0019]

[0020] Wherein: n=1-10, R is H, CH 3 or CF 3 .

Embodiment 2

[0021] Example 2. In the epoxy resin composition for semiconductor encapsulation described in embodiment 1, described R is H and CF 3 .

Embodiment 3

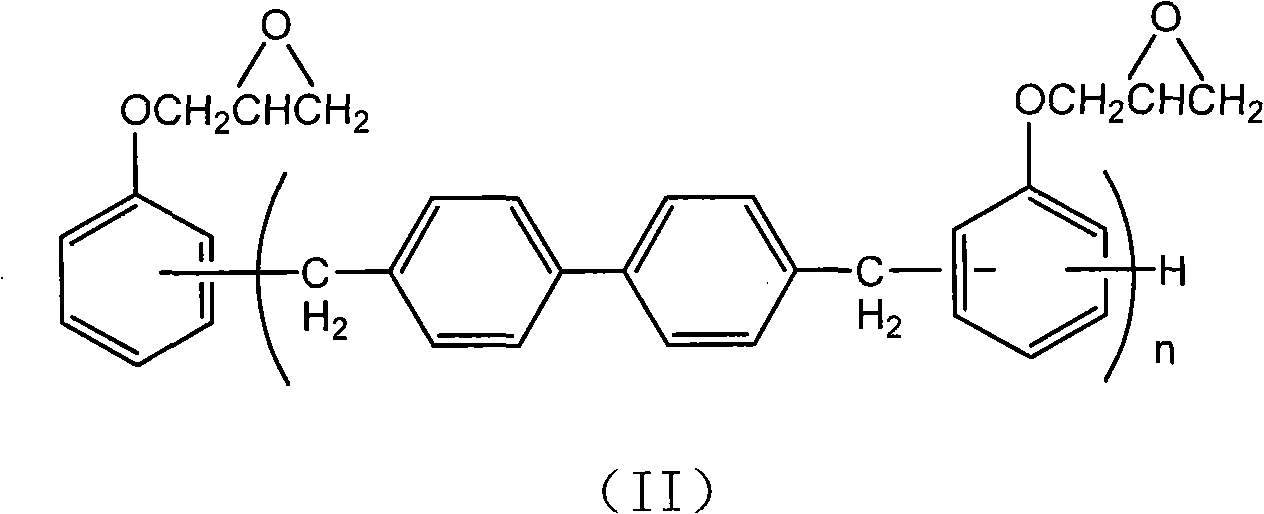

[0022] Example 3. In the epoxy resin composition for semiconductor encapsulation described in embodiment 1 or 2, described epoxy resin is the epoxy resin that structural formula is (II):

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com