Desulfuration method of clean coal

A technology for cleaning coal and coal samples, which is applied in the field of coal processing to achieve the effects of improved combustion performance, low energy consumption and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

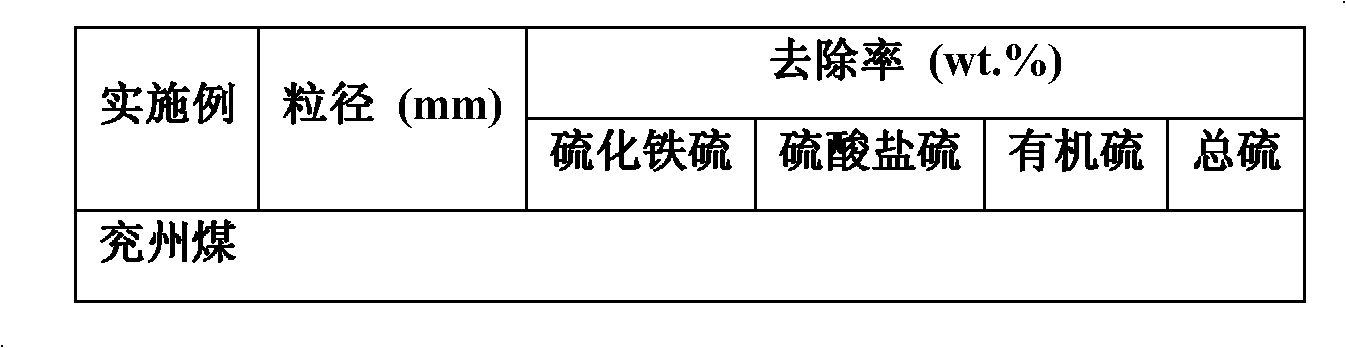

[0021] Examples 1-6: Effects of Different Particle Sizes on the Removal of Sulfur in Various Forms

[0022]

[0023]

[0024] At 30°C, put 3g of coal samples with particle sizes of 0.85mm, 0.106mm and 0.075mm into 50ml of water for low-speed homogenization for about 30min, then add 0.003g of NaBH 4 , Stir the coal slurry for 1min and stop. The results showed that the removal rate of total sulfur increased with the decrease of particle size, and the removal rate of organic sulfur increased significantly. When the coal particle size is 0.075mm, the total sulfur removal rates of Yanzhou coal and Yanshan coal are 42.9% and 53.1%, respectively. Among them, the removal rates of iron sulfide sulfur, sulfate sulfur and organic sulfur in Yanzhou coal were 35.6%, 89.2% and 18.3% respectively; the removal rates of iron sulfide sulfur, sulfate sulfur and organic sulfur in Qianshan coal were 72.3%, 100% and 26.8% respectively. %.

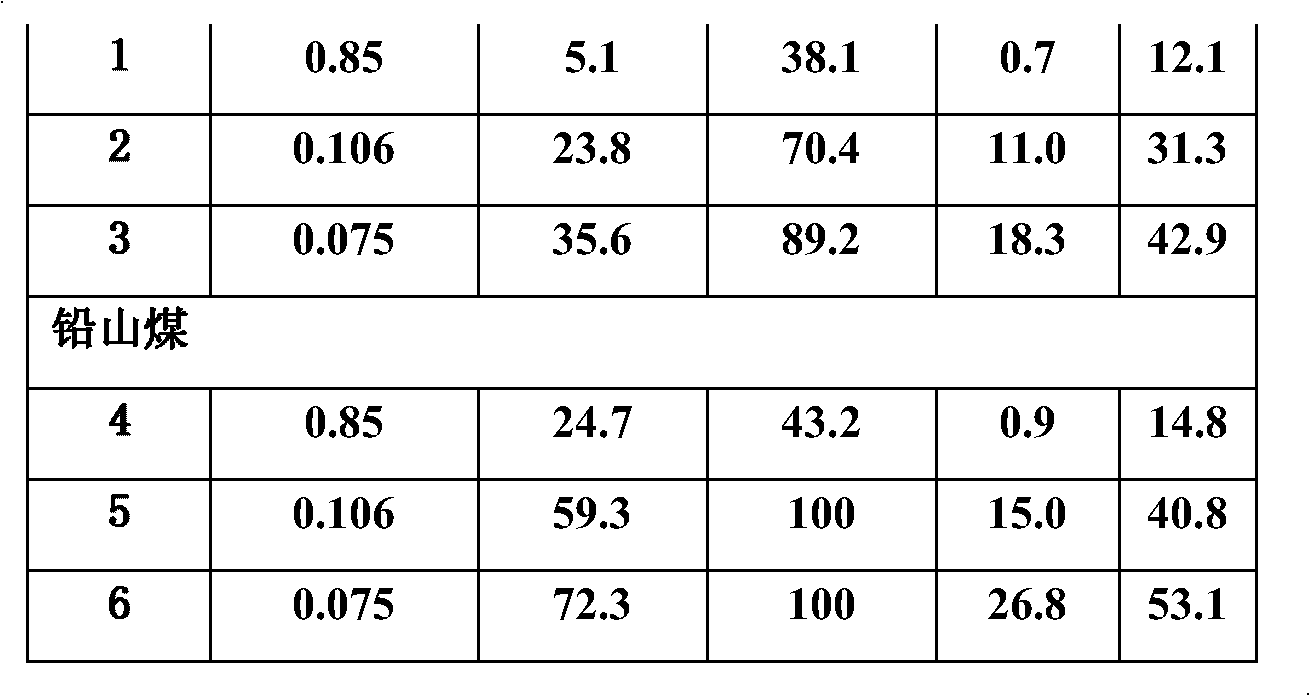

Embodiment 7~9

[0025] Embodiment 7~9: the influence of different liquid media on total sulfur removal rate

[0026]

[0027] Under the condition of 30°C, put 3g of coal samples with particle size of 0.18mm in 50ml of water, 50ml of methanol and 50ml of ethanol and homogenize at low speed for about 30min, then add 0.003g of NaBH 4 , Stir the coal slurry for 1min and stop. The results show that the total sulfur removal rates of Yanzhou coal and Yanshan coal range from 26.3 to 28.9% and 32.7 to 35.2%, respectively.

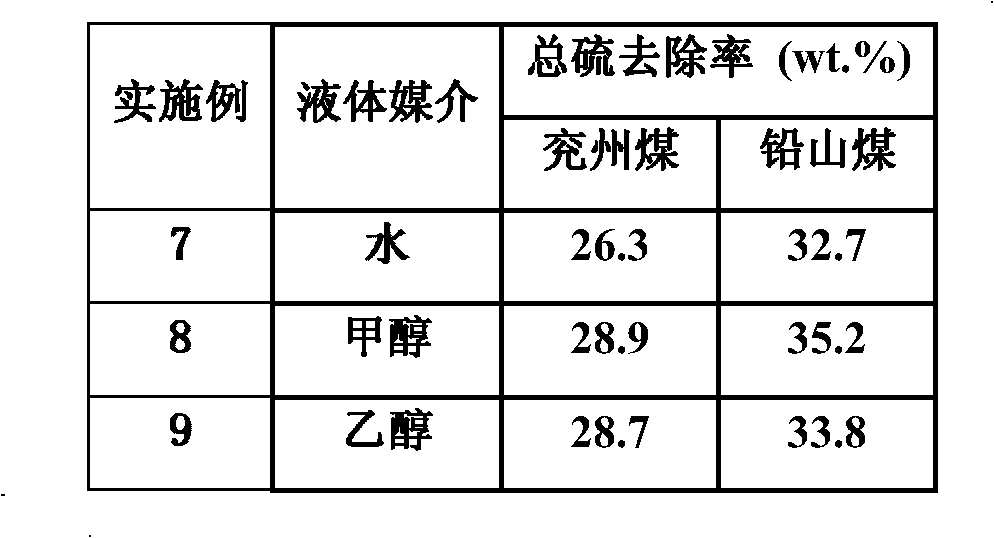

Embodiment 10~12

[0028] Embodiment 10~12: the influence of different temperatures on total sulfur removal rate

[0029]

[0030] Under the conditions of 4°C, 30°C and 60°C, put 3g of coal samples with a particle size of 0.18mm into 50ml of water for low-speed homogenization for about 30min, then add 0.003g of NaBH 4 , Stir the coal slurry for 1min and stop. The results show that the total sulfur removal rates of Yanzhou coal and Yanshan coal range from 23.1 to 27.7% and 30.1 to 33.8%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com