Severe magnesium leakage accident protection system for magnesium alloy melting furnace

A kind of accident prevention and melting furnace technology, applied in the direction of furnace, crucible furnace, furnace type, etc., can solve the problems of endangering the safety of equipment and personnel, waste, limited capacity of leakage collector, etc., to solve malignant leakage accidents and solve safety protection Problems, flexible and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

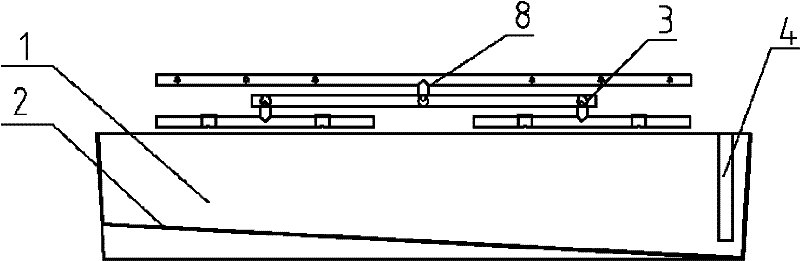

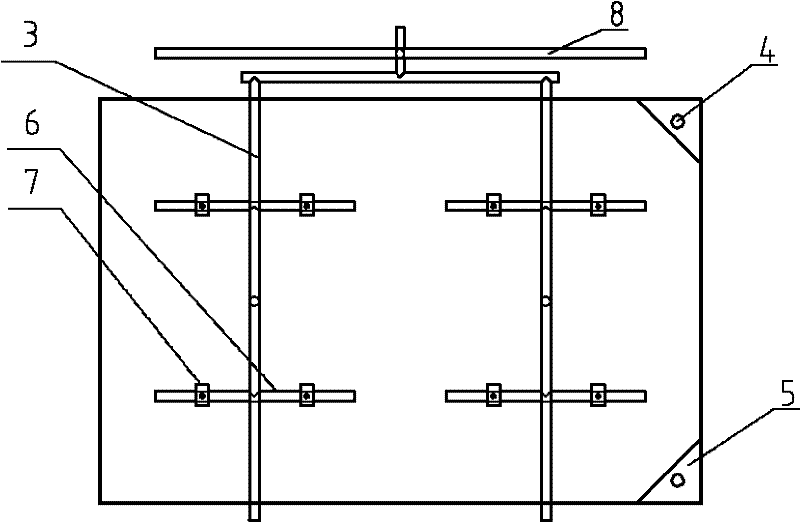

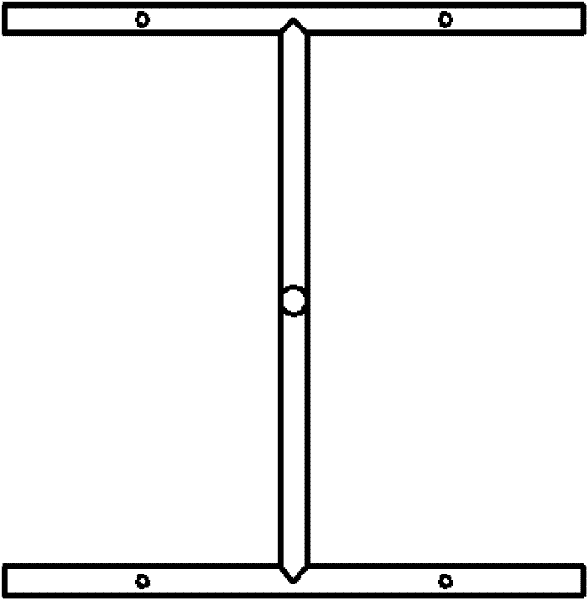

[0017] refer to Figure 1-3 , a protection system for the malignant magnesium leakage accident of a magnesium alloy melting furnace, including a magnesium leakage detection device, a magnesium leakage collection system that can completely contain the magnesium liquid in the melting furnace and is easy to pull out from the furnace, and a gas protection system that starts in time; the magnesium leakage The collection system is a magnesium leakage pan 1, the magnesium leakage pan 1 is provided with a double-layer bottom plate, and the upper bottom plate 2 is inclined; the gas protection system includes a ventilation pipe 3 that transports the protective gas to the magnesium leakage pan, and the The ventilation pipe 3 is arranged on the magnesium leakage tray 1, and is installed on the furnace frame. The first gas distributor 6 to ensure that the gas is evenly distributed is provided under the ventilation pipe 3, and communicates with the ventilation pipe 3 through the ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com