Infrared gas detection system suitable for oil-containing gas analysis of reservoir

A gas detection system and gas analysis technology, which are applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of large operating space, high price, affecting the consistency of spectral data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

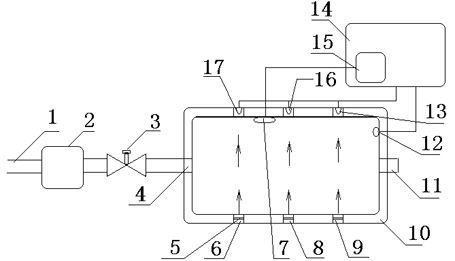

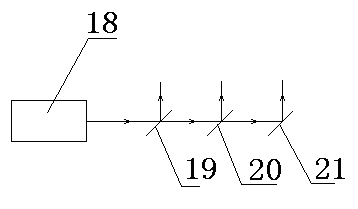

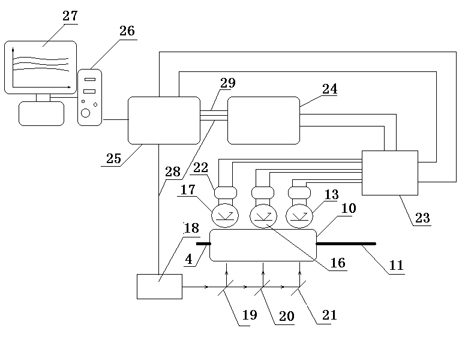

[0023] Such as figure 1 Shown: an infrared gas detection system suitable for oil and gas gas analysis in reservoirs, including a vacuum pump 2 used to send the gas desorbed during the drilling process to a steady flow through the desorbed gas pipeline 1 after dust removal and drying treatment Device 3, after the flow rate is stabilized by the flow stabilization device 3, the gas enters through the detection chamber inlet 4 and is continuously discharged from the detection chamber outlet 11. The detection chamber 10 includes a temperature control mechanism 15 for constant temperature heating of the heating element 7 in the detection chamber 10 Control so that the detection chamber 10 forms a constant temperature gas chamber, and one end of the gas path perpendicular to the constant temperature gas chamber includes light hydrocarbons, heavy hydrocarbons, CO 2 Three beams of infrared light sources at the absorption peak wavelengths of the three gases are light hydrocarbon gas inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com