Device and method for detecting heat-dissipating plate

A detection device and detection method technology, applied in the direction of measurement device, electrical device, radiation pyrometry, etc., to achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

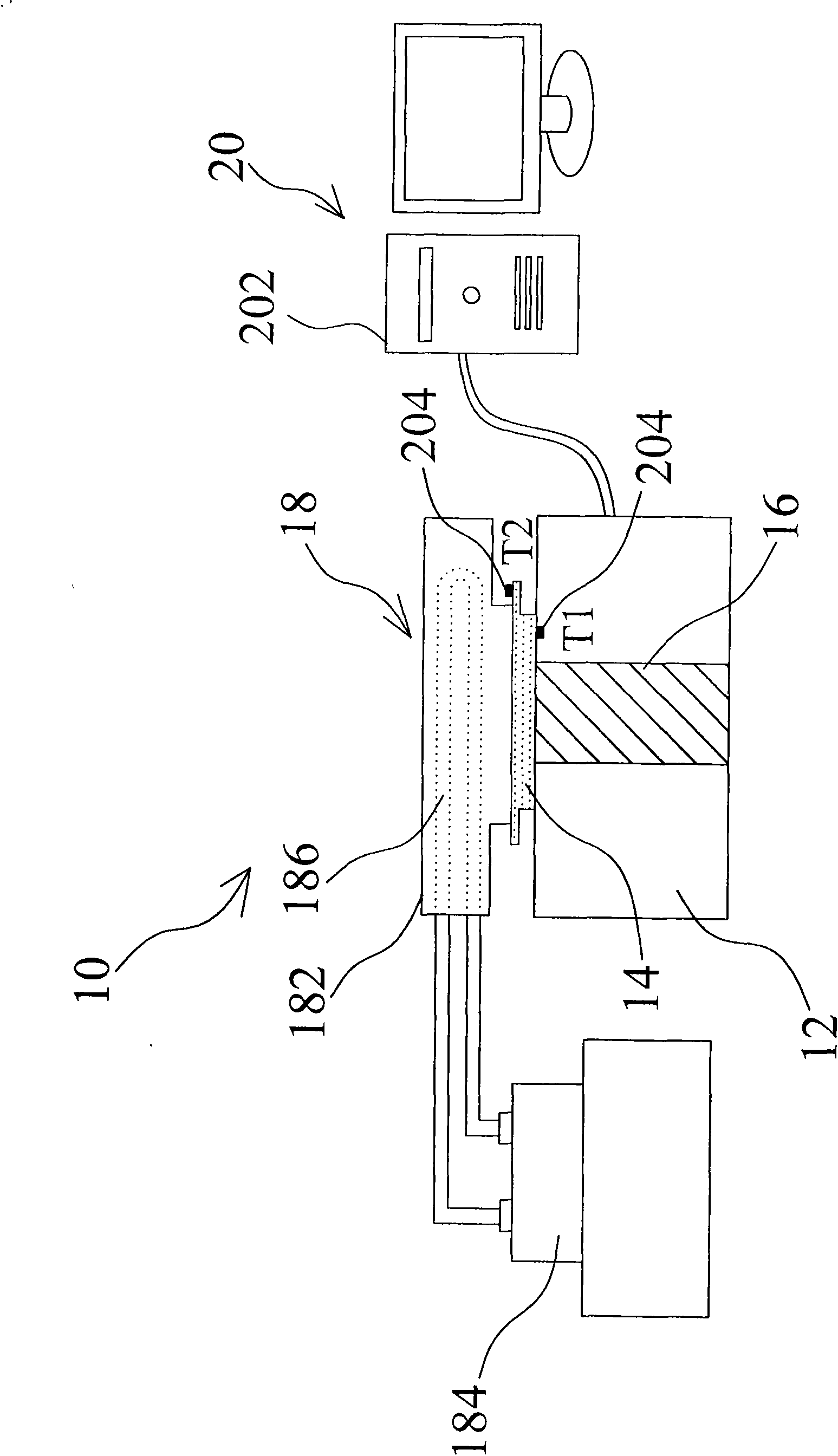

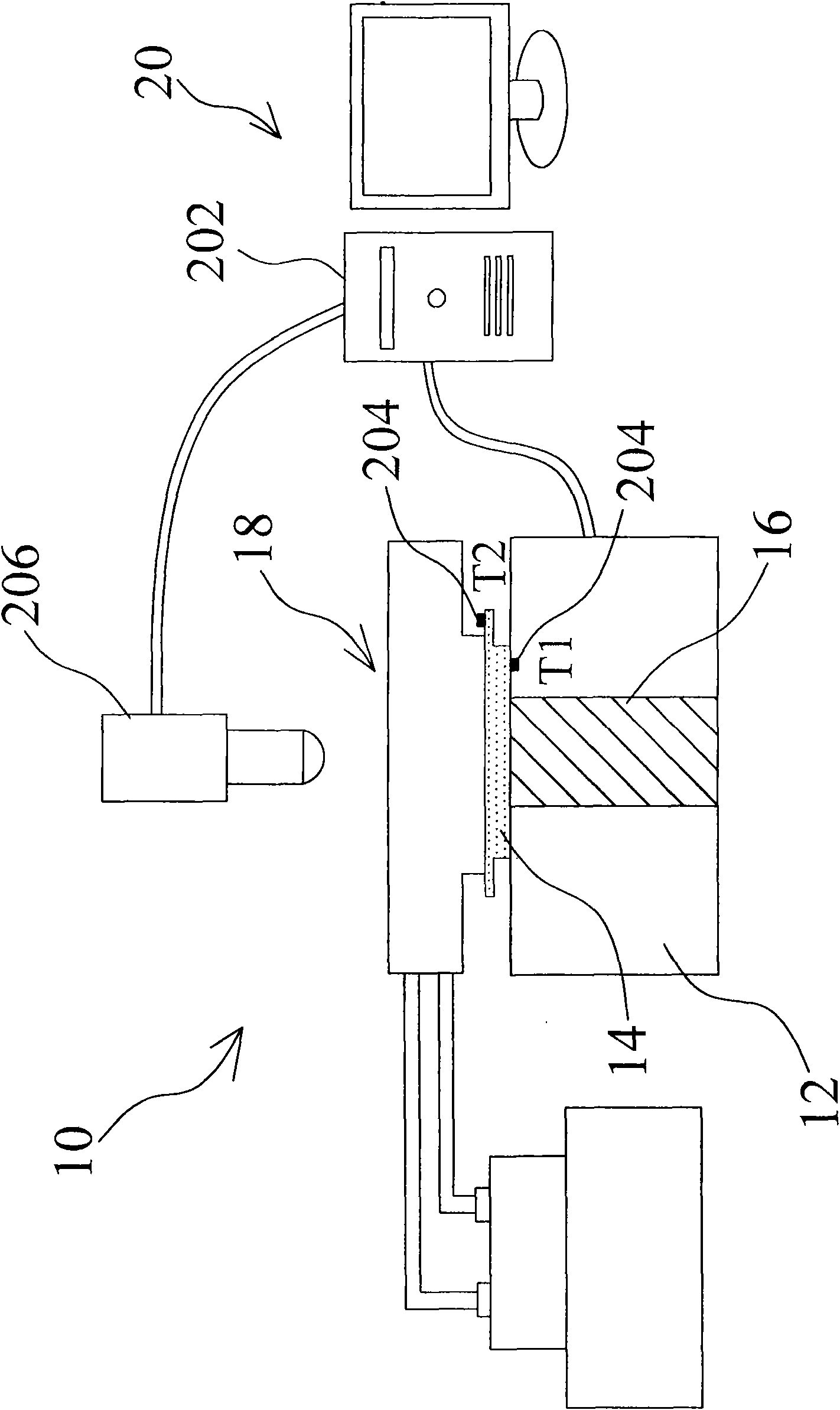

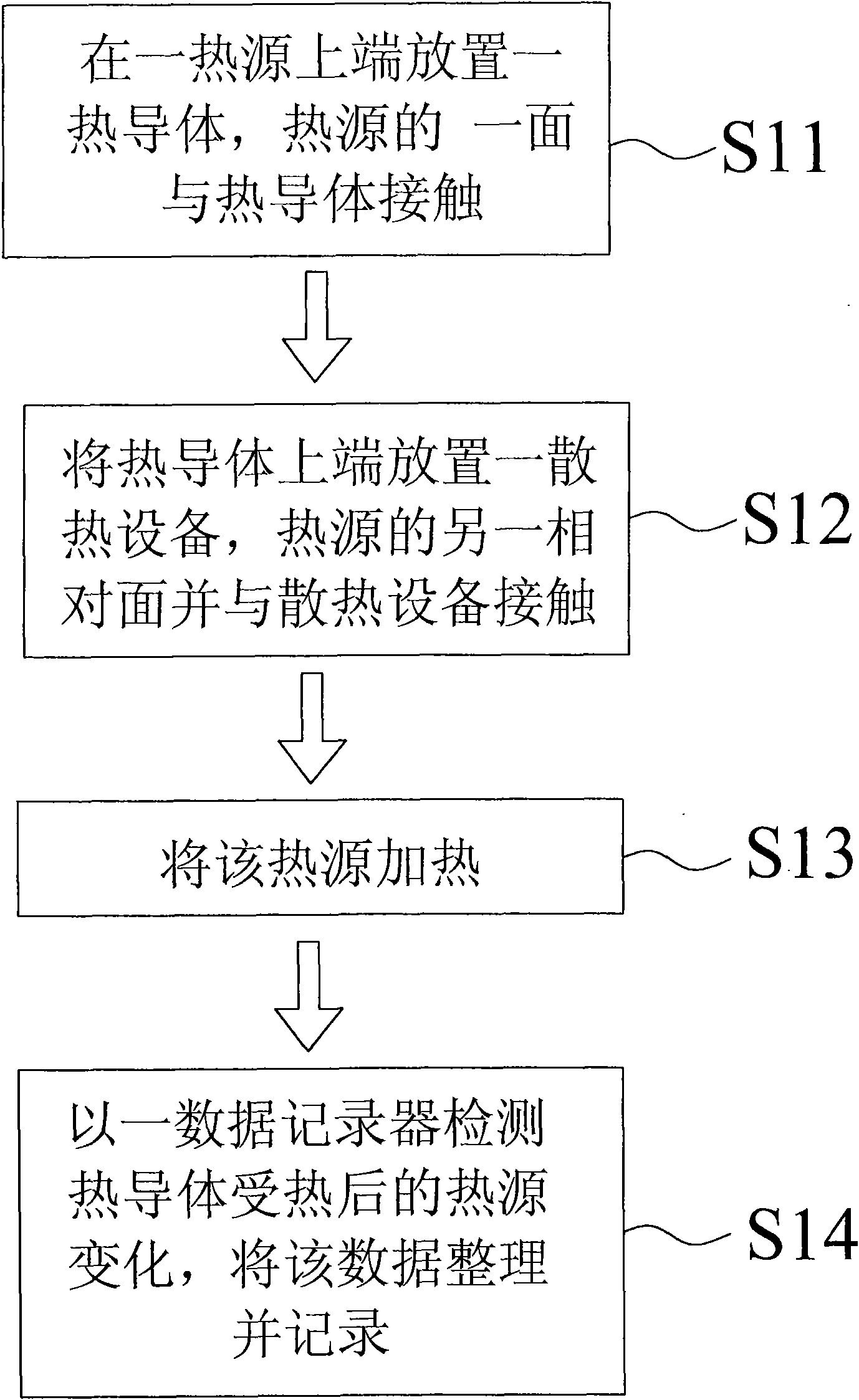

[0016] figure 1 It is a schematic diagram of the structure of the heat dissipation plate detection device of the present invention. As shown in the figure, the present invention is a heat dissipation plate detection device 10, including a detection platform 12, and the detection platform 12 is mainly for placing a thermal conductor 14. In this embodiment, the thermal conductor It is a vapor chamber; a heat source 16, the heat source 16 can provide heat energy, and is in contact with the heat conductor 14, the heat source 16 can make point contact or surface contact with the heat conductor 14, and the heat source 16 can be a light-emitting diode or an electric heating rod, etc., which can release heat energy Device; a heat dissipation device 18, which is in contact with the heat conductor 14, and can quickly remove the heat on the heat conductor 14. The heat dissipation device 18 can be a condensation rod, an air conditioner, a heat dissipation fan, an aluminum heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com