Expert system and control method applied to blast furnace-converter sector production scheduling process control of steel enterprises

A technology of production scheduling and expert system, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of strong adaptability and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The substantive content of the present invention will be further described below with examples in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

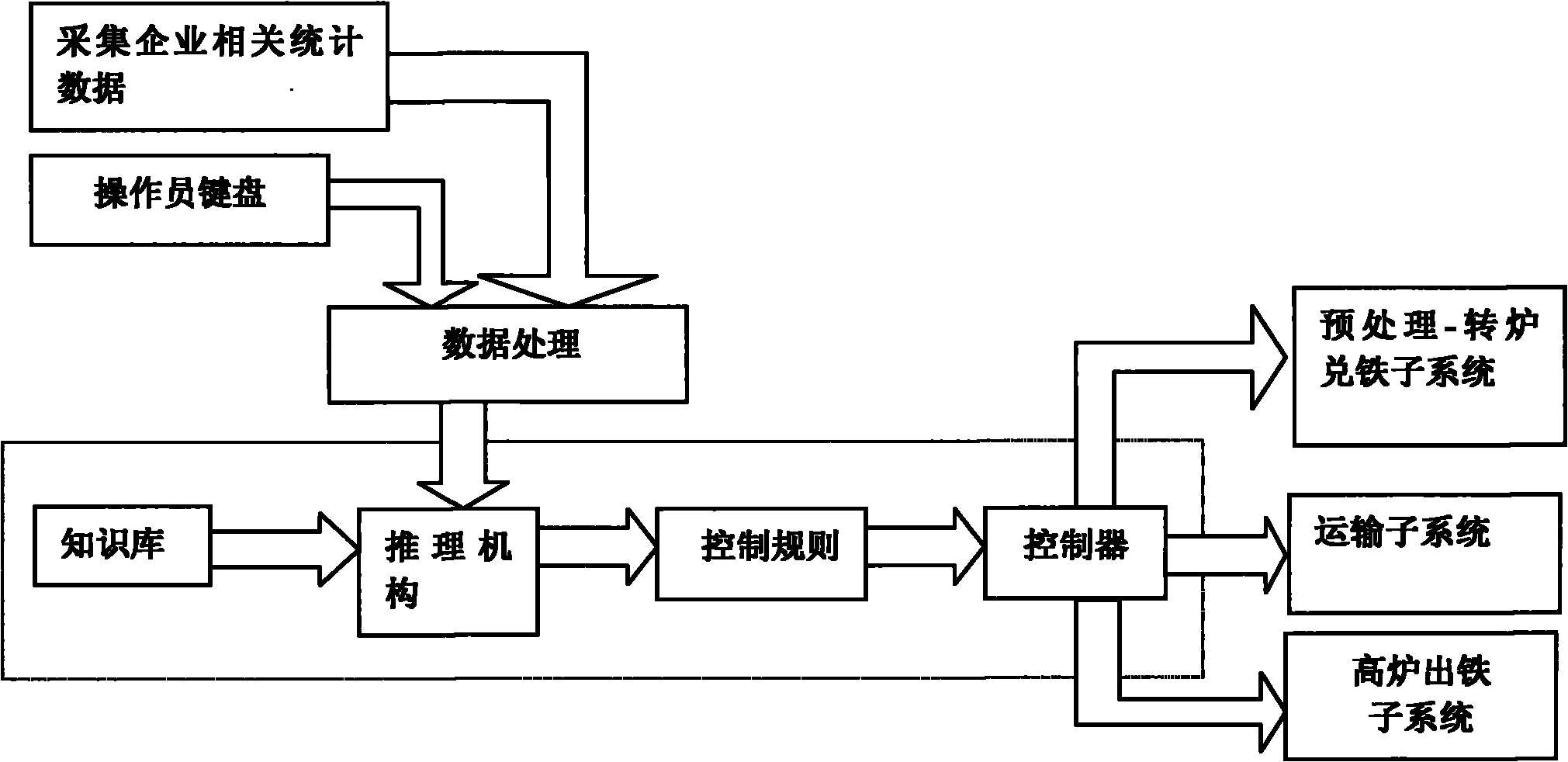

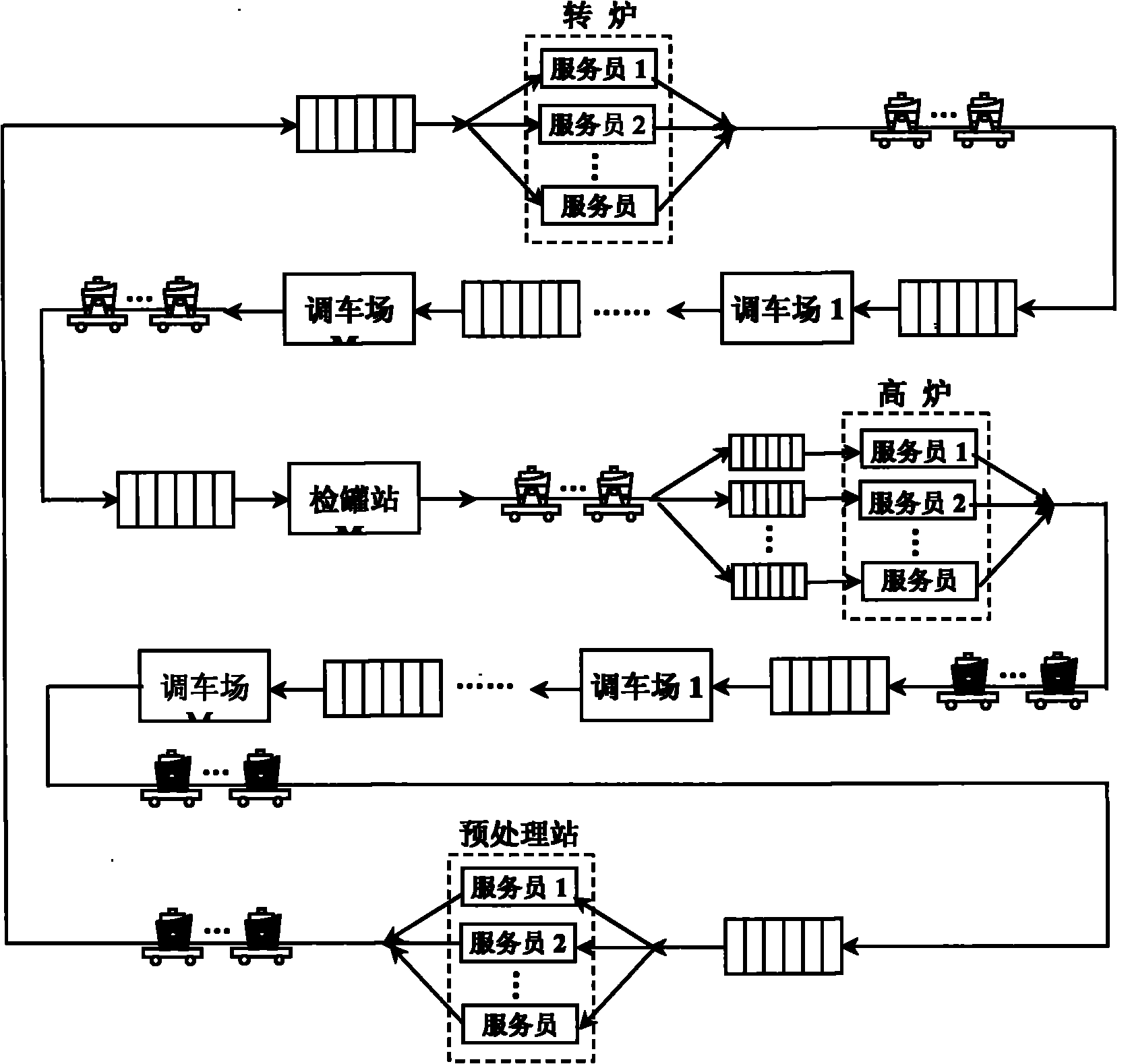

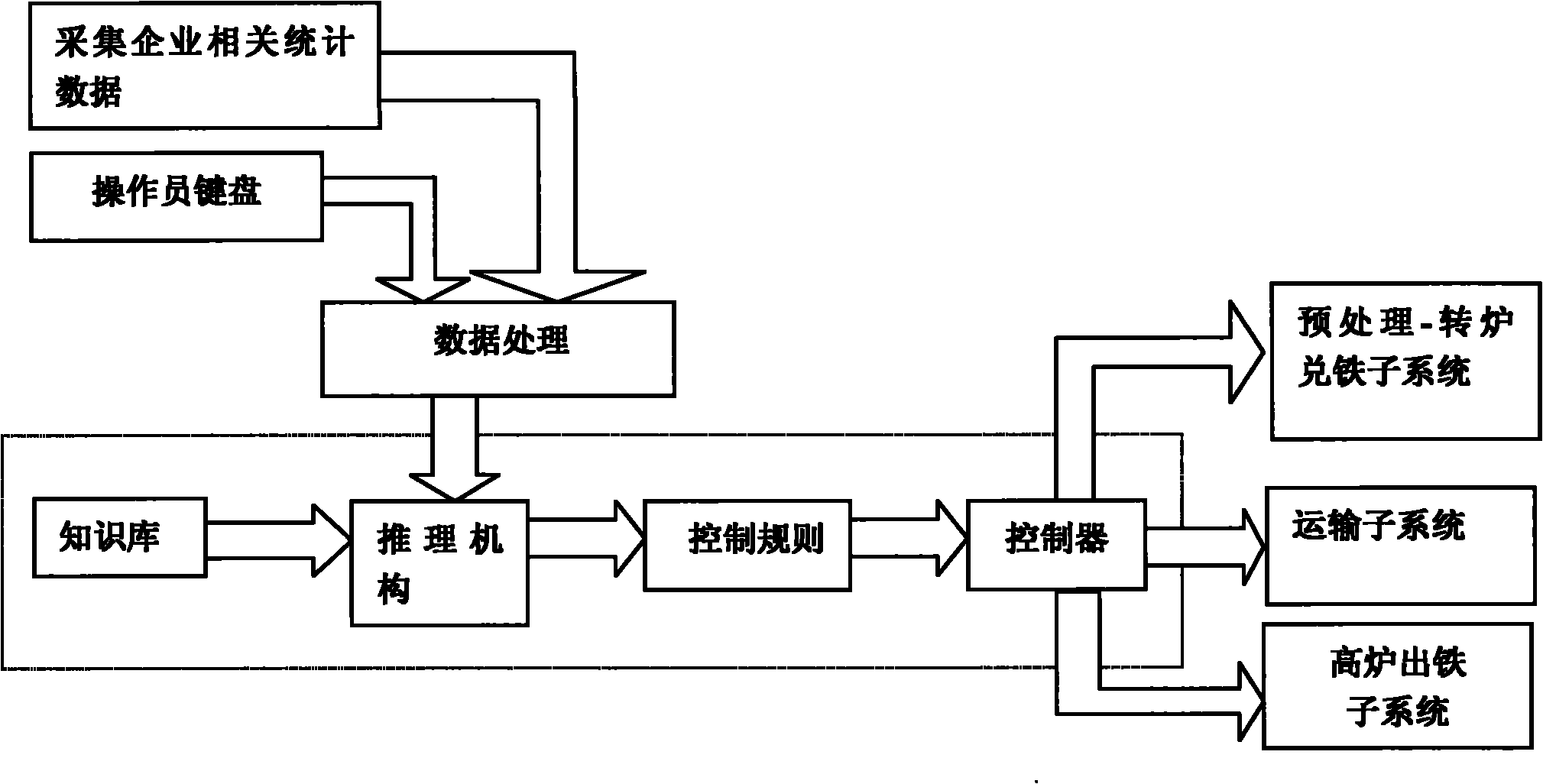

[0043] Such as figure 1 and figure 2 , the expert system applied to the production scheduling process control of blast furnace-converter section in iron and steel enterprises is composed of knowledge base, control rule set, reasoning mechanism and information processing part, which integrates the operation experience of workers and supplements it with queuing theory method and system Simulation and other theories are used to reason and judge, make necessary decisions, and guide reasonable production scheduling. The expert system applied to the production scheduling process control of the blast furnace-converter section in iron and steel enterprises is characterized in that the knowledge base is used to store empirical data, performance indicators and empirical fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com