Quick shutdown system and method of industrial sewing machine

A technology for industrial sewing machines and parking systems, applied in the direction of stopping devices, etc., can solve problems such as unsatisfactory reliability and safety, unstable stopping process, affecting production efficiency, etc., so as to improve system reliability and safety, and improve reliability. Safety and security, the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

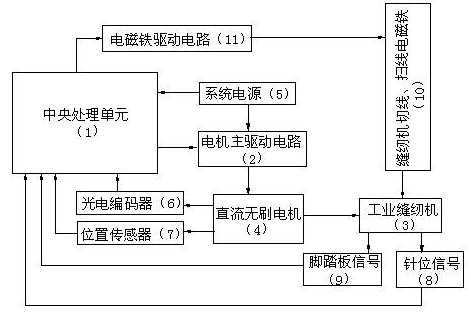

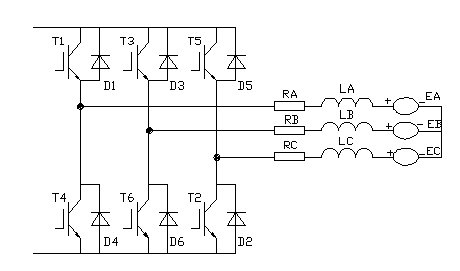

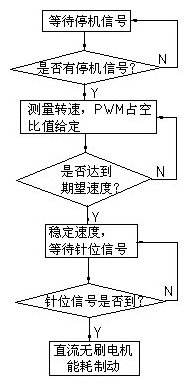

[0019] Embodiment 1: the industrial sewing machine quick stop system of the present embodiment, as figure 2 As shown, it includes a central processing unit 1 , a motor main drive circuit 2 and a DC brushless motor 4 that controls the operation of an industrial sewing machine 3 . The motor main drive 2 circuit includes a bridge stack circuit composed of six switch tubes T1~T6, such as figure 1 As shown, the three switch tubes T1, T3 and T5 form the upper bridge arm, and the three switch tubes T4, T6 and T2 form the lower bridge arm. In this embodiment, the six switch tubes T1-T6 are selected as field effect tubes. The drains of the effect transistors T1, T3 and T5 are connected in parallel, the sources of the field effect transistors T4, T6 and T2 are connected in parallel, the drain of the upper bridge arm and the source of the lower bridge arm constitute the input end of the bridge stack circuit, and the bridge stack The input end of the circuit is connected to the system p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com