Constant speed universal joint

A technology of constant velocity universal joints and outer joints, which is applied to gear transmission mechanisms, furnace types, couplings, etc., can solve the problems of reduced life of punches, easy damage of punches, and increased number of processes to achieve increased strength , the effect of inhibiting quenching cracking and inhibiting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the best mode for carrying out the present invention will be described.

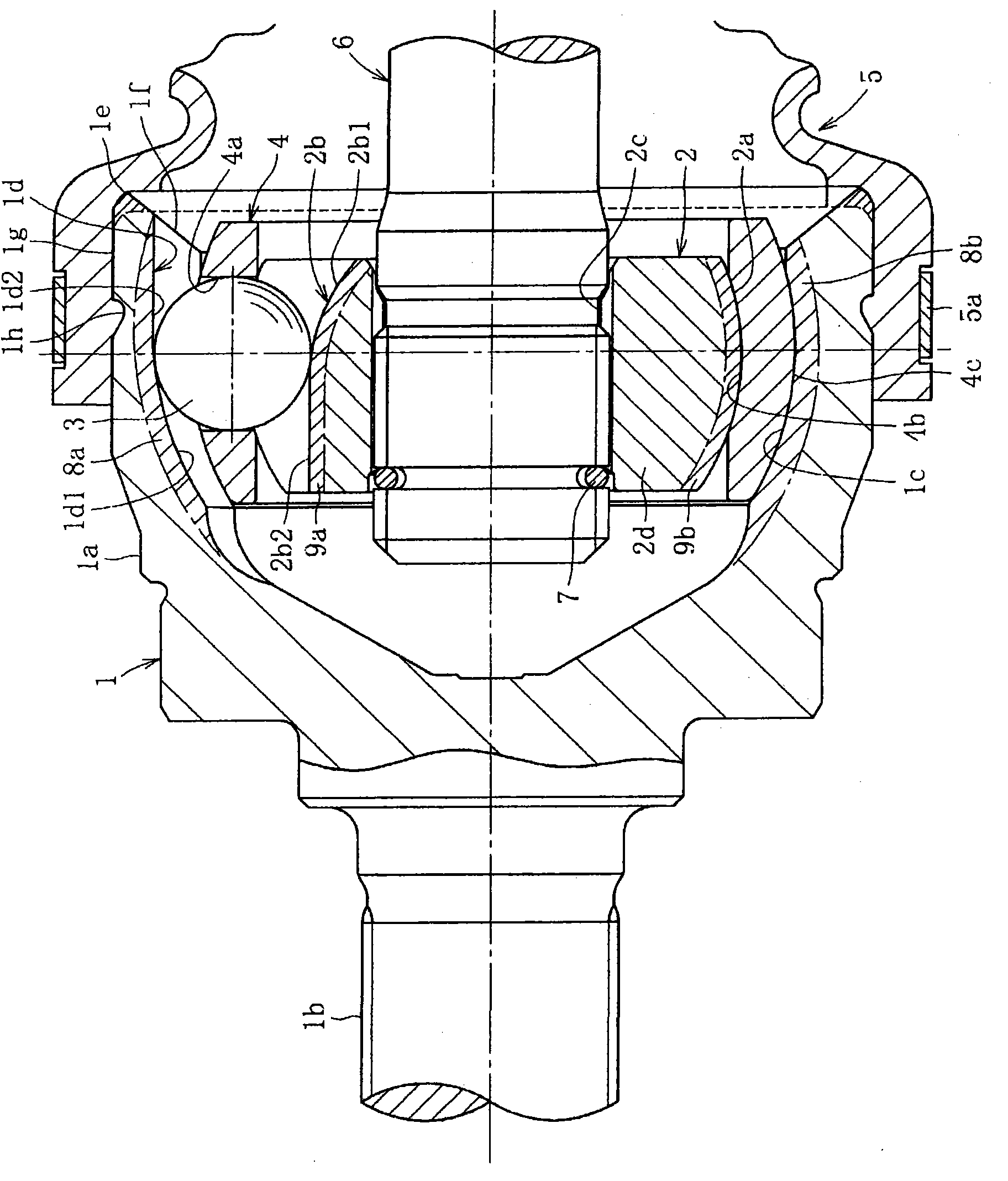

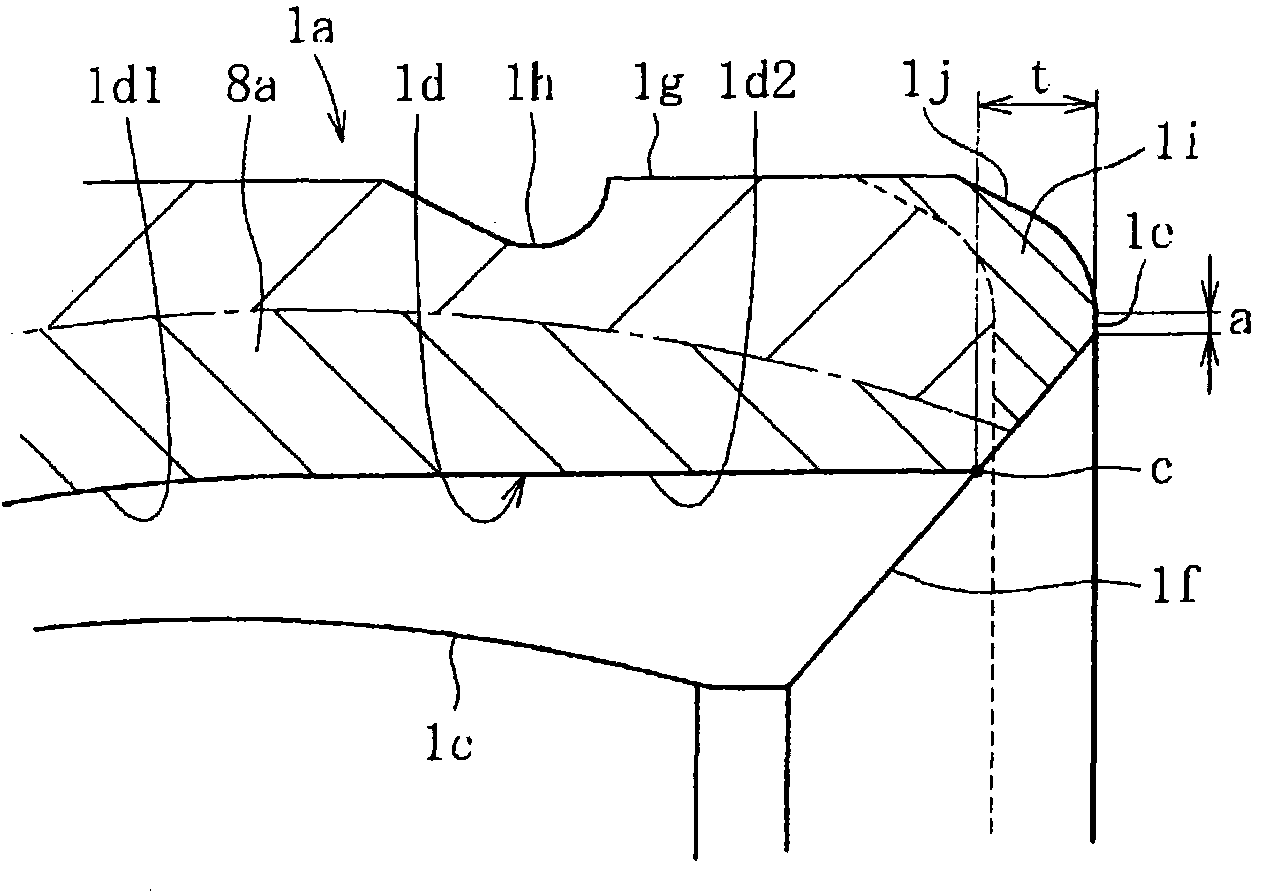

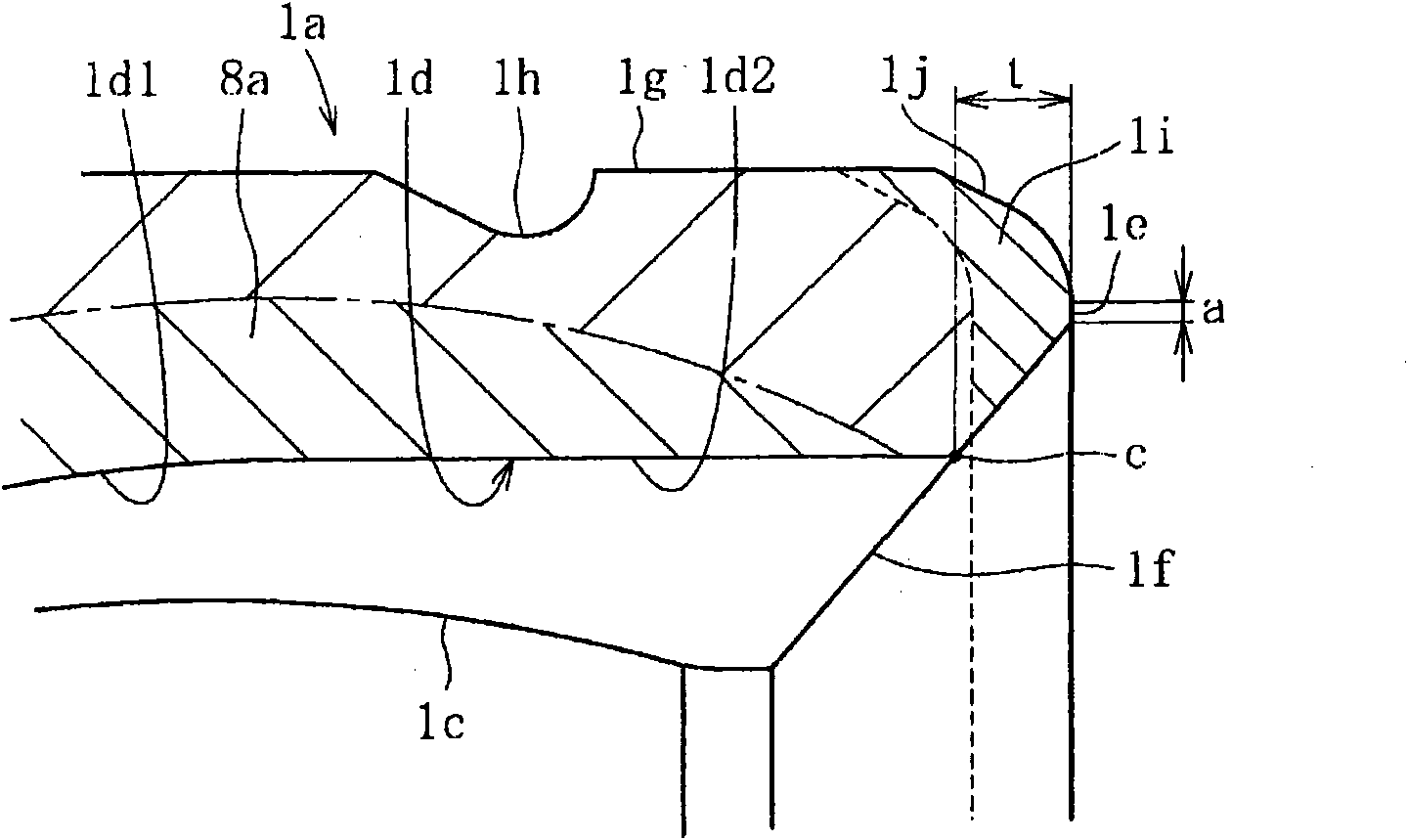

[0055] figure 1 An undercut-free constant velocity universal joint (hereinafter referred to as UJ) according to an embodiment of the present invention is illustrated. This UJ includes an outer joint member 1 , an inner joint member 2 , a ball 3 , and a cage 4 as main components. The outer joint member 1 is composed of a cup-shaped portion 1a with one opening and a rod portion 1b. The cup-shaped portion 1a has a track groove 1d formed on the inner peripheral surface 1c, a tapered escape surface 1f that is continuous from the inner peripheral surface 1c to the opening end surface 1e, and a hole for attaching the protective cover 5 formed on the outer peripheral surface 1g. Circumferentially extending boot groove 1h.

[0056] The inner joint member 2 is positioned inside the cup-shaped portion 1a of the outer joint member 1, and has a spherical outer peripheral surface 2a. A track g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com