Microwave desulfurization equipment

A microwave desulfurization and equipment technology, which is applied in industrial flue gas treatment and environmental protection fields, can solve problems such as insufficient energy utilization, high operating costs, and reactor corrosion, and achieve the effects of low cost, improved processing capacity, and high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

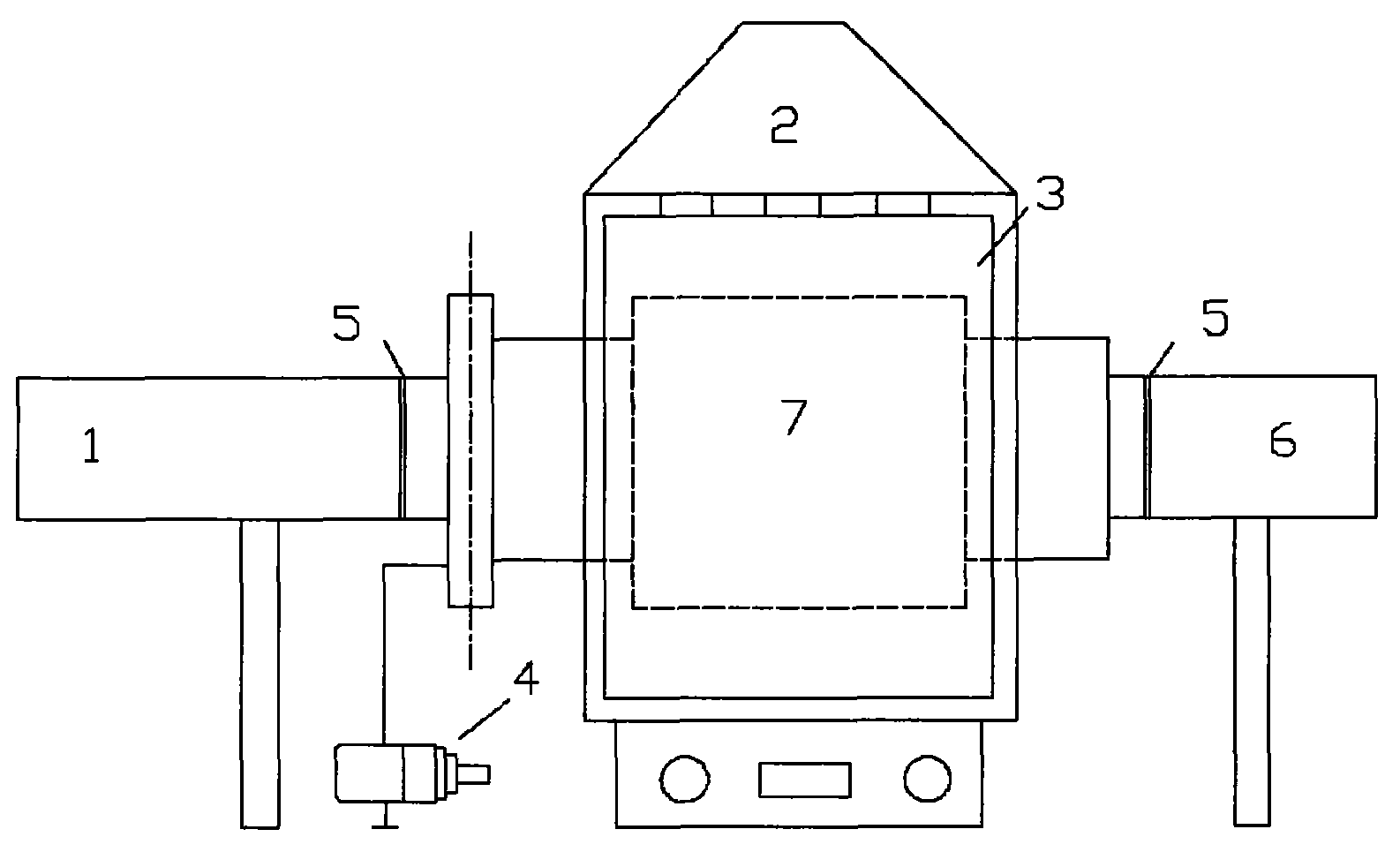

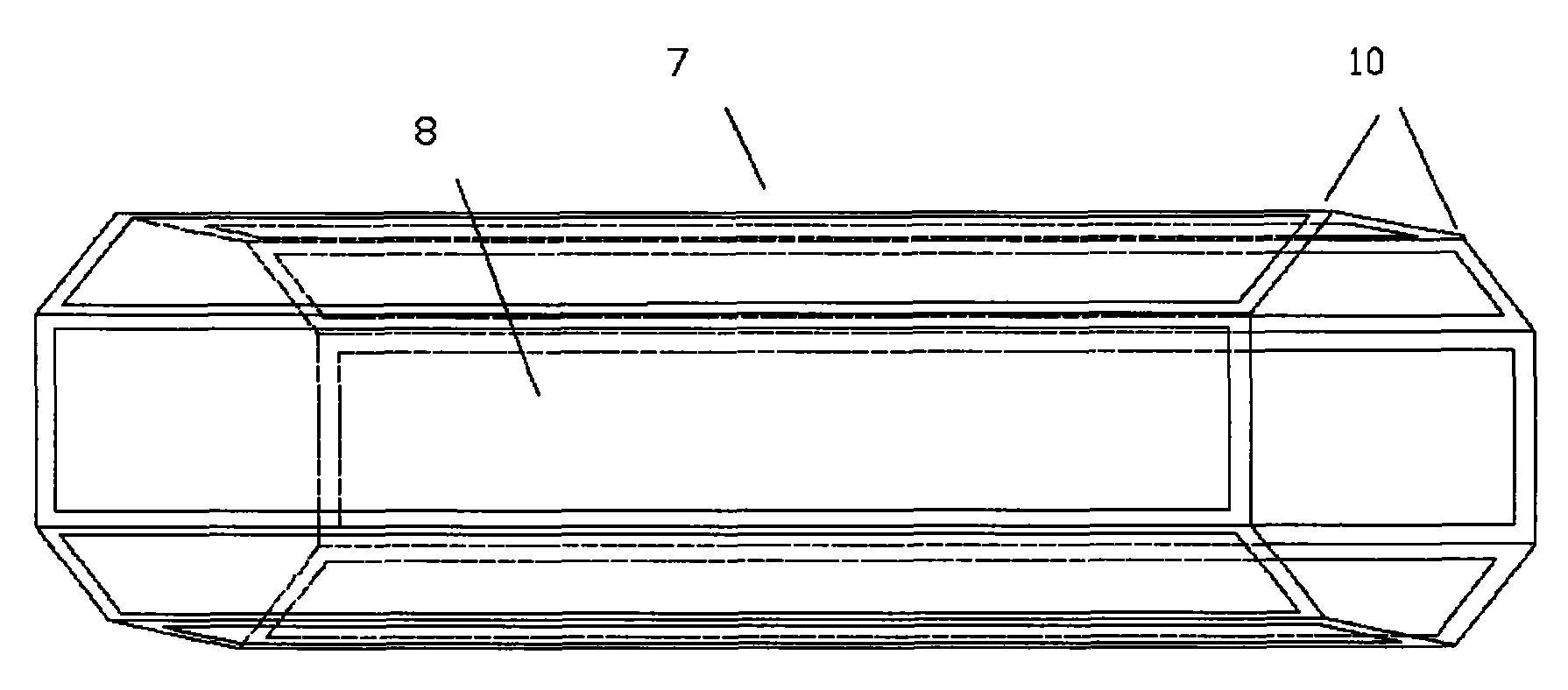

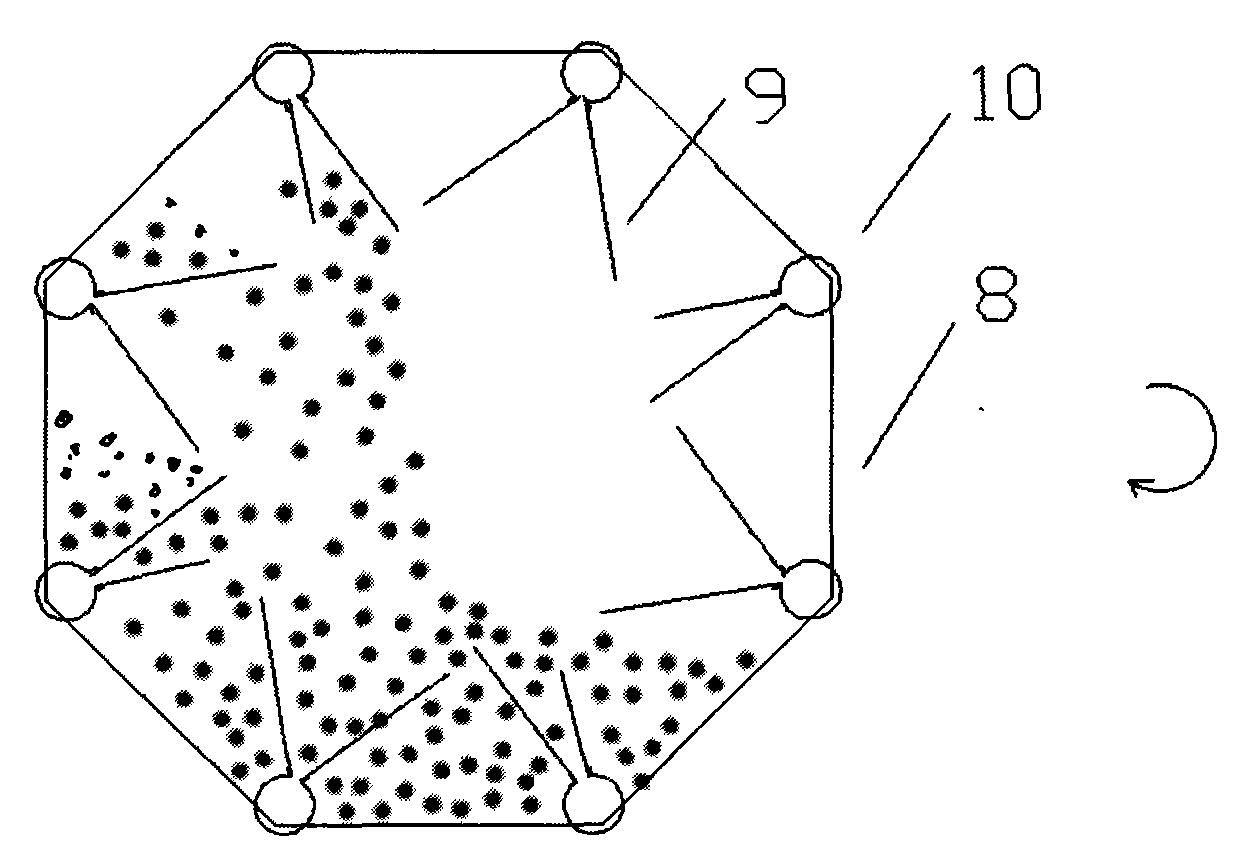

[0025] Such as Figure 1 ~ Figure 3 As shown, a microwave desulfurization equipment of the present invention includes a microwave resonant cavity 3 in which activated carbon can circulate, a microwave suppressor 5 outside the resonant cavity, a microwave generator 2, a rotary drive device 4, a flue gas input device 1 and a flue gas output Device 6 has six parts. The flue gas output device includes elemental sulfur recovery and condensation equipment. Activated carbon is built in the microwave resonant cavity, and the drum inside the microwave resonant cavity is connected with the rotary drive device outside the microwave resonant cavity, and is driven by the rotary drive device to rotate. regular replenishment. In this embodiment, the drum is horizontally built into the microwave resonant cavity, and is made of a material through which microwaves can pass through completely or partially; structurally, it consists of a quartz glass sheet, a stainless steel frame and ribs 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com