Sintering ore burdening method

A sintering ore and scheme technology, applied in the field of iron and steel metallurgy, can solve problems such as the difficulty of reasonably and accurately controlling the sintering process, and achieve the effects of reducing experimental workload and labor intensity, small experimental errors, and good experimental reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

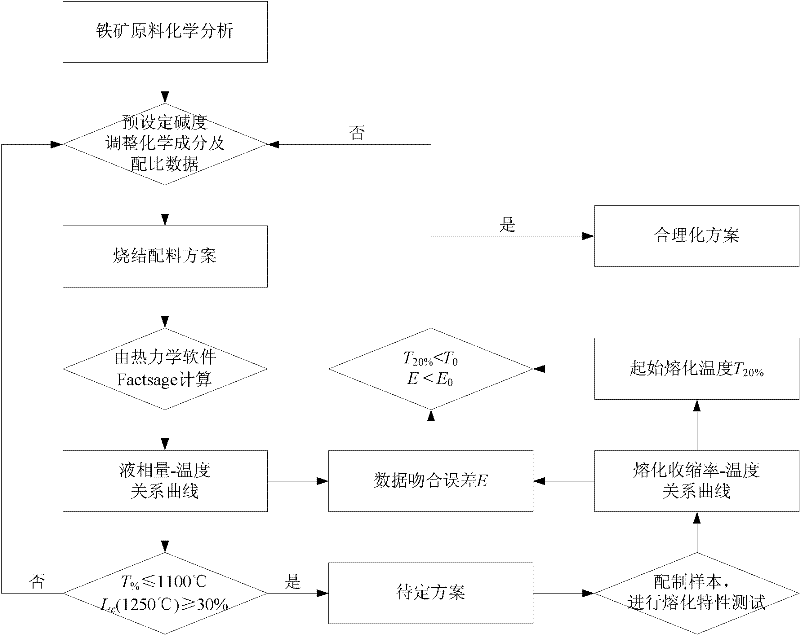

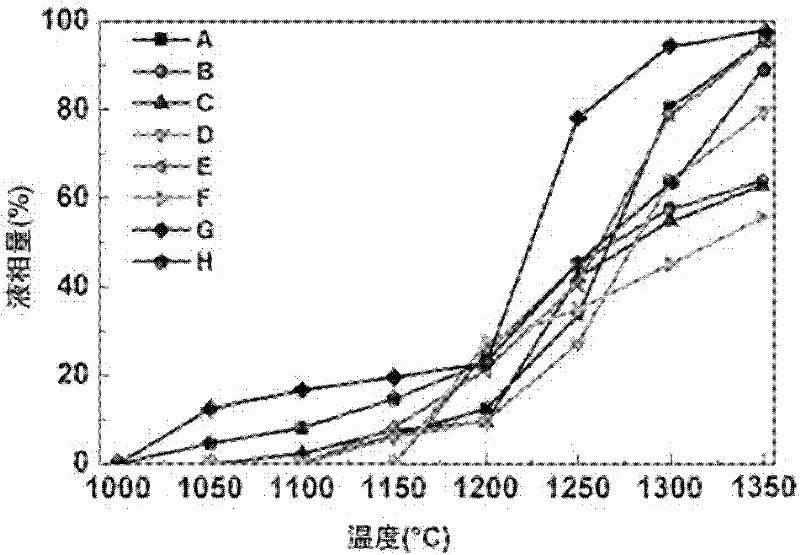

[0070] In this embodiment, 8 kinds of iron ores used by an enterprise for sintering are selected, each of which has a different sintering batching scheme. During the analysis and research, the chemical composition and ratio data of the 8 iron ores were analyzed and confirmed by conventional chemical analysis methods. In order to reduce the complexity of the calculation and improve the accuracy, this embodiment only considers the main oxide components in the ore; for the existing form of Fe in the iron ore, according to the ratio of TFe and FeO, it is converted into Fe 2 o 3 and Fe 3 o 4 form. Then, in this embodiment, the binary alkalinity of the sintered ore is preset to be 2.0, and the chemical composition and ratio data of the 8 iron ores are adjusted respectively to obtain 8 groups of sintering batching schemes from A to H. These 8 groups of sintering batching schemes One-to-one correspondence with 8 kinds of iron ore. The chemical composition and proportioning ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com