Method for manufacturing positive pole plate of lithium-ion capacitor and lithium-ion capacitor using same

A production method and lithium ion technology, applied in capacitor electrodes, capacitor parts, liquid electrolytic capacitors, etc., can solve problems such as large differences in specific gravity, difficulty in slurry coating, and difficulty in forming a stable and uniform slurry. The effect of unstable slurry, easy mass production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

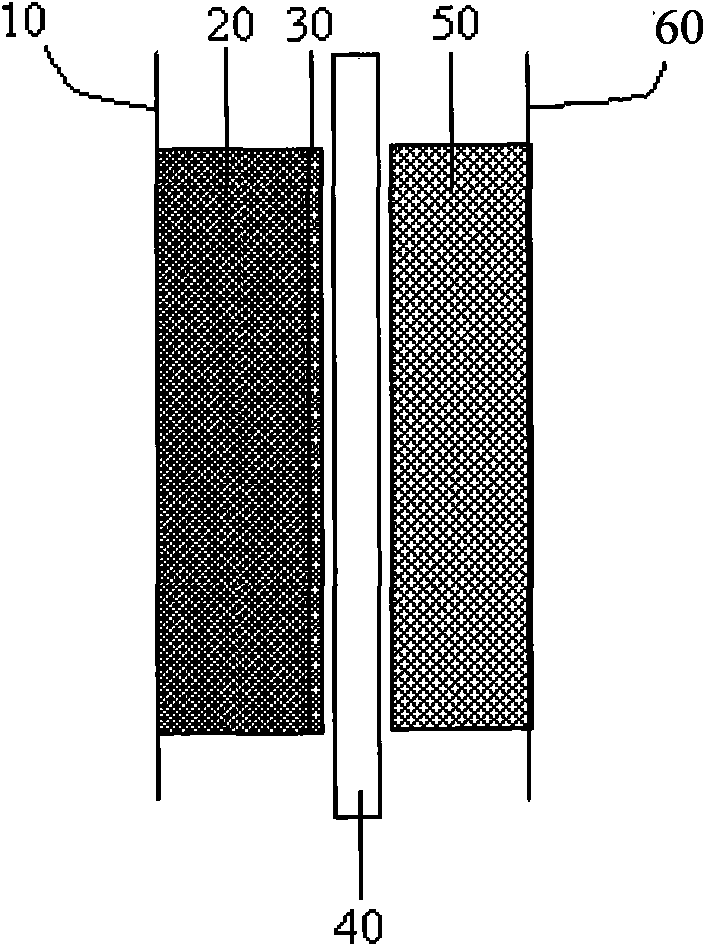

Image

Examples

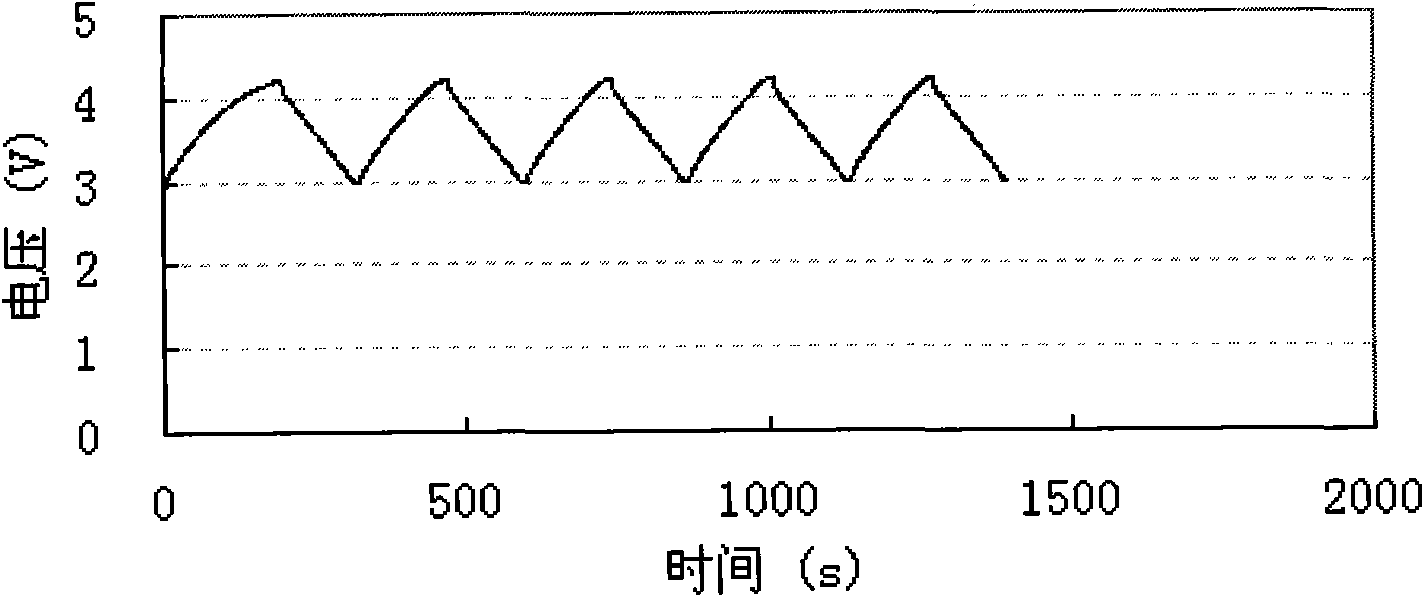

specific Embodiment Embodiment 1

[0029] The preparation of lithium-ion capacitor positive plate: special activated carbon for supercapacitor (1800m 2 / g) and conductive agent SuperP, adhesive polyvinylidene fluoride (PVDF) according to the mass ratio of 87:3:10 to make a slurry, coated on the current collector aluminum foil and dried at 120 ° C, the coating amount is 6.51 mg / cm 2 ; Lithium cobaltate, conductive agent SuperP, and binder PVDF are mixed uniformly at a mass ratio of 95:2.5:2.5 to make a certain viscosity lithium-ion battery positive electrode slurry, which is coated on the current collector aluminum foil coated with a layer of activated carbon. Its coating amount is 4.13mg / cm 2 , after drying at 120°C, cold pressing is carried out; the positive electrode sheet prepared according to the above process is baked at a high temperature of 180°C for 40 minutes, and after edge trimming, cutting, and striping, a lithium ion capacitor meeting the requirements is made Positive sheet.

[0030] Preparation...

Embodiment 2

[0034] The preparation of lithium-ion capacitor positive plate: special carbon fiber (2100m 2 / g) and conductive agent SuperP, binder PVDF according to the mass ratio of 87:3:10 to make a slurry, coated on the current collector aluminum foil and dried at 120 ° C, the coating amount is 12.53mg / cm 2 ; Mix lithium manganate, conductive agent SuperP, and binder PVDF according to the mass ratio of 95:2.5:2.5 to make a certain viscosity lithium ion battery positive electrode slurry, and coat it on the current collector aluminum foil coated with a layer of carbon fiber , coating amount is 6.68mg / cm 2 , after drying at 120°C, cold pressing is carried out; the positive electrode sheet prepared according to the above process is baked at a high temperature of 180°C for 40 minutes, and after trimming, cutting, and slitting, a lithium-ion capacitor meeting the requirements is made Positive sheet.

[0035] Preparation of lithium-ion capacitor negative electrode sheet: soft carbon, conduct...

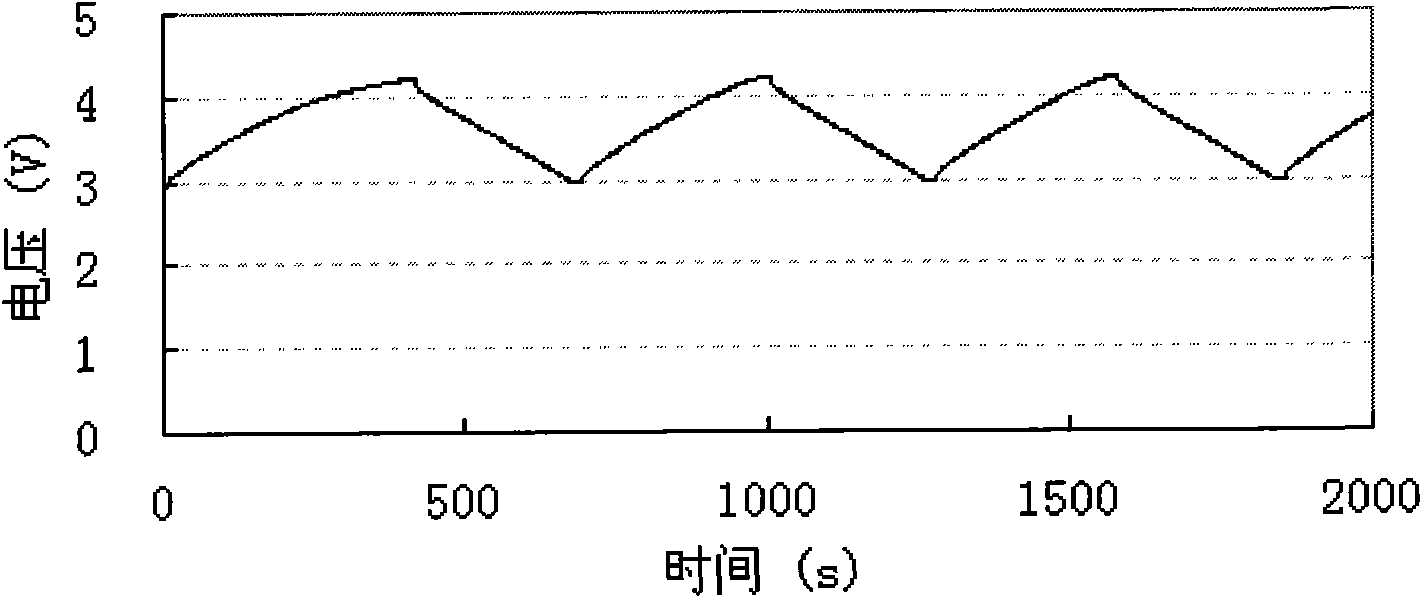

Embodiment 3

[0038] The preparation of lithium-ion capacitor positive plate: special activated carbon for supercapacitor (2300m 2 / g) and conductive agent SuperP, binder PVDF according to the mass ratio of 87:3:10 to make a slurry, coated on the current collector aluminum foil and dried at 120 ° C, the coating amount is 8.75mg / cm2 ; Mix lithium iron phosphate, conductive agent SuperP, and binder PVDF according to the mass ratio of 95:2.5:2.5 to make a certain viscosity lithium ion battery positive electrode slurry, and coat it on the current collector aluminum foil coated with a layer of activated carbon , coating amount is 5.16mg / cm 2 , after drying at 120°C, cold pressing is carried out; the positive electrode sheet prepared according to the above process is baked at a high temperature of 180°C for 40 minutes, and after trimming, cutting, and slitting, a lithium-ion capacitor meeting the requirements is made Positive sheet.

[0039] Preparation of lithium-ion capacitor negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com