Gas feeding device, treating device, treating method, and storage medium

一种气体供给、气体的技术,应用在薄料处理、电气元件、运输和包装等方向,能够解决没有记载气体解决方法等问题,达到自由度大、容易制造、生产率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

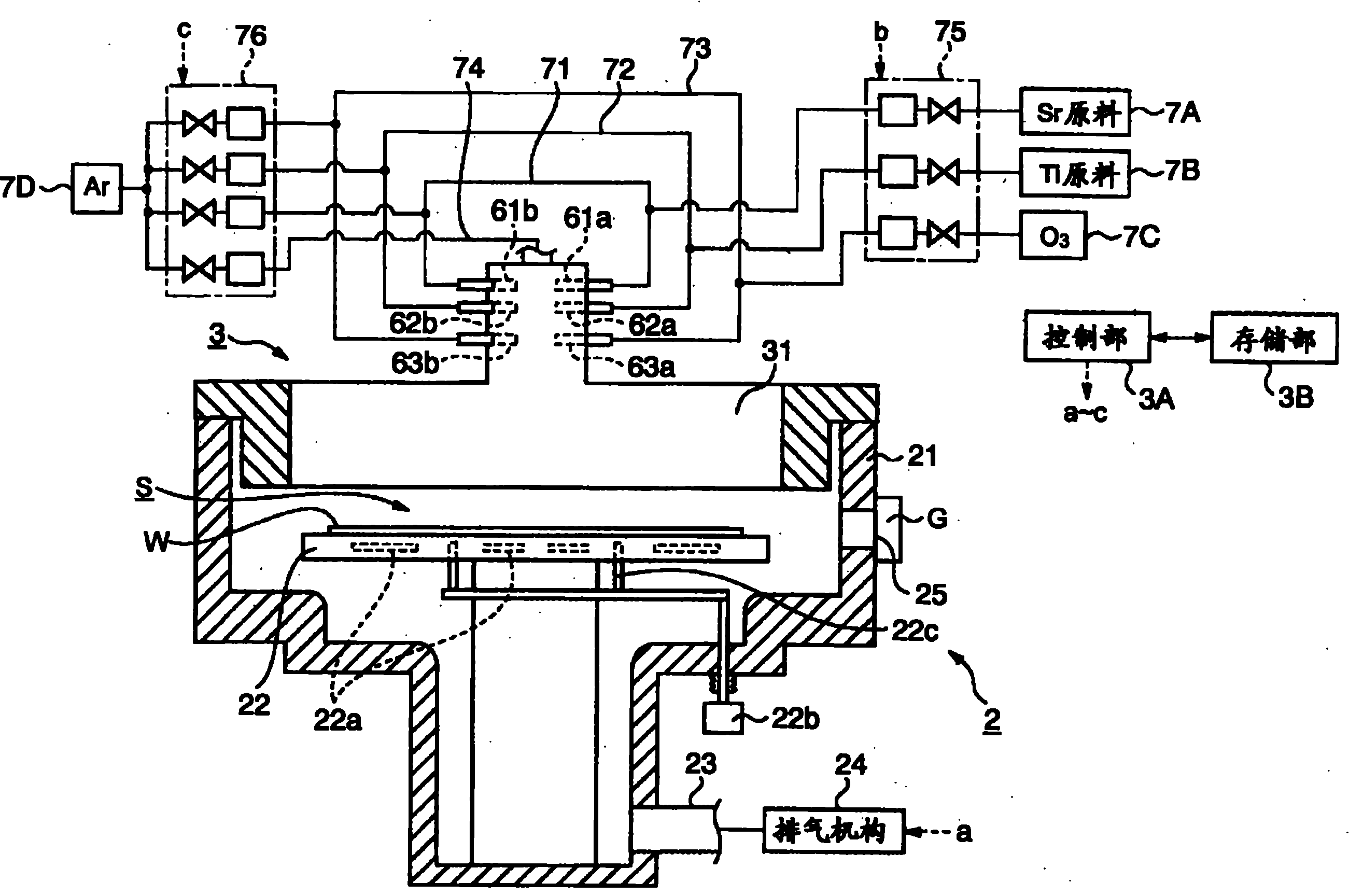

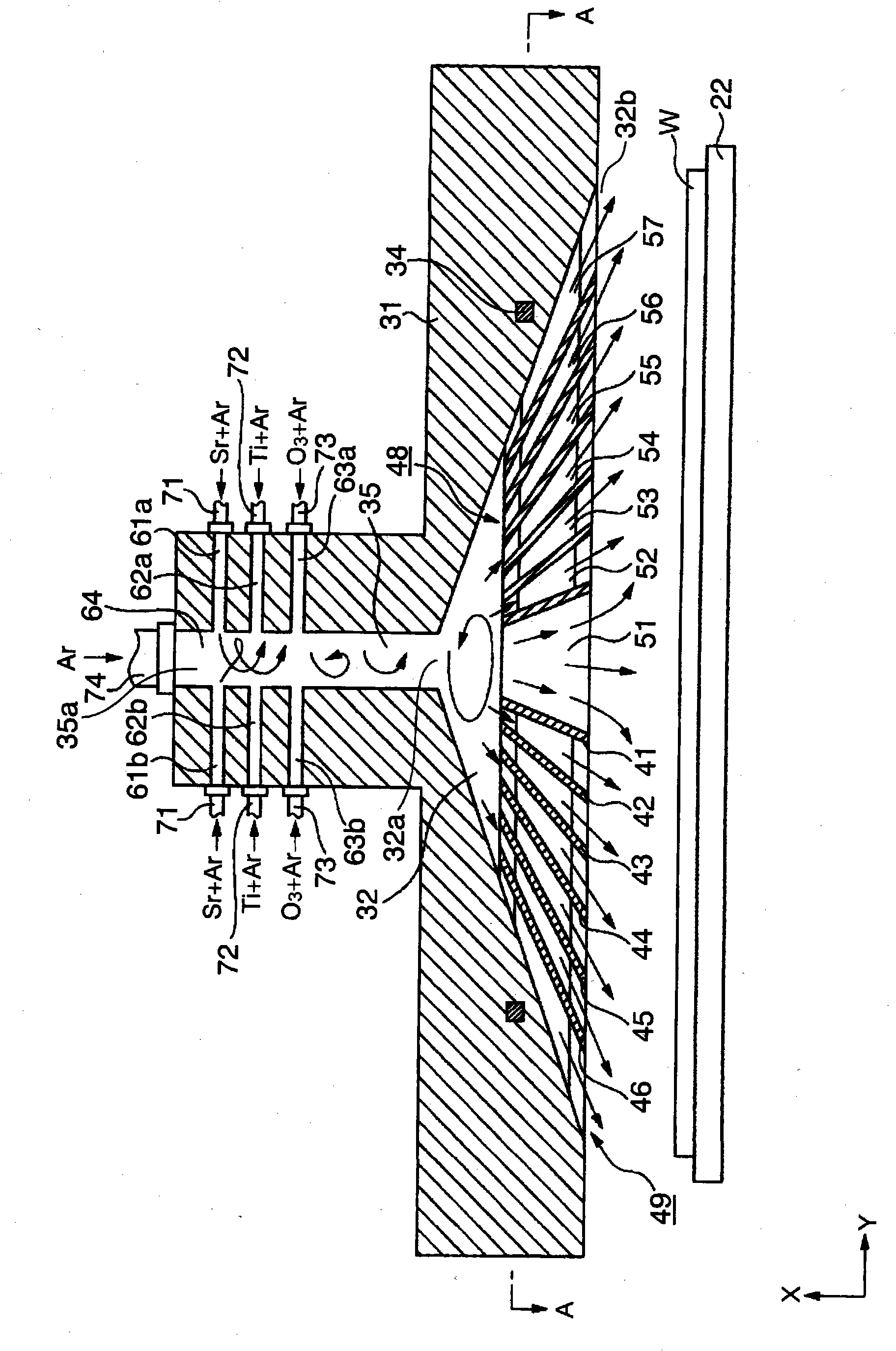

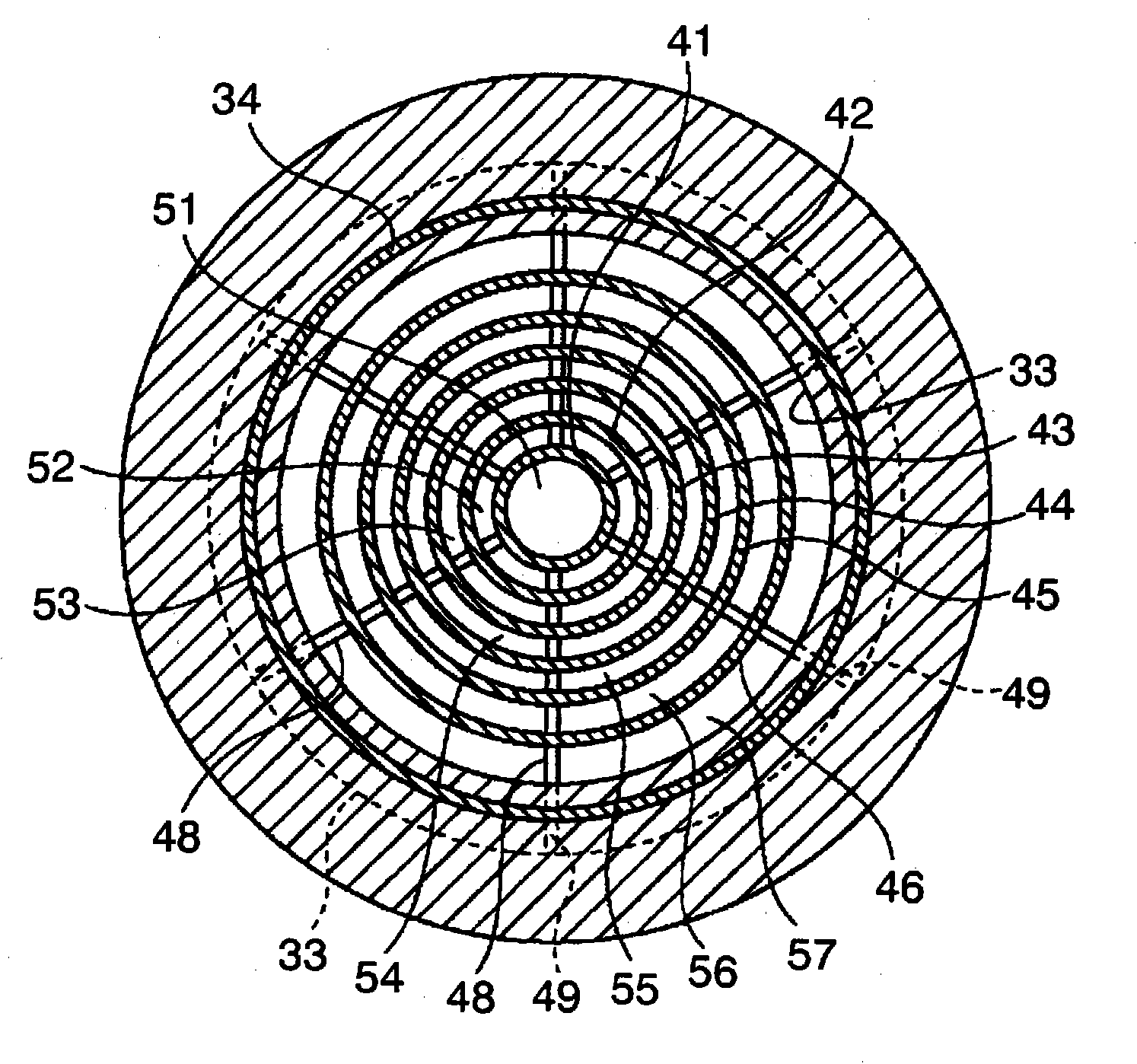

[0053] First, edge reference figure 1 , the overall configuration of the film forming apparatus 2 as an embodiment of the present invention will be described.

[0054] The film forming apparatus 2 of the present embodiment has a function of using, for example, a source gas containing strontium (Sr) (hereinafter referred to as Sr source gas) as the first process gas, and a source gas containing titanium (Ti) (hereinafter referred to as referred to as Ti raw material gas) as the second processing gas, and make these gases and ozone (O 3 ) gas reaction, using the ALD process to form strontium titanate (SrTiO 3 , hereinafter abbreviated as STO) film.

[0055] The film forming apparatus 2 includes a processing container 21 . In the processing container 21, a mounting table 22 for horizontally mounting the wafer W is provided. Inside the mounting table 22, a heater 22a constituting a temperature adjustment mechanism for the wafer W is provided. In addition, three lift pins 22c...

no. 2 approach

[0093] Next, in reference to Figure 11 Along with (a), a second embodiment of the gas supply device constituting the gas supply unit of the above-mentioned film forming apparatus 2 will be described.

[0094] Although Figure 11 The gas supply unit 100 shown in (a) has the same configuration as the gas supply unit 3, however, the above-mentioned dividing members 41 to 46 are not provided in the gas circulation space 32, and instead of them, the gas circulation space 32 is divided in the circumferential direction. Plate-shaped partition members 103-106 arranged in a manner. Each of the partition members 103 to 106 extends radially from the center of the gas circulation space 32 toward the inner peripheral surface 33 of the main body portion 31 .

[0095] For example, one end of each partition member 103-106 is supported by the said inner peripheral surface 33, and the other end is supported by the support member 107 provided in the center of the said radial direction. Figu...

no. 3 approach

[0101] Next, a third embodiment of the gas supply device constituting the gas supply unit of the above-described film forming apparatus 2 will be described. In referring to the sectional perspective view as this embodiment Figure 12 At the same time, the description will focus on the differences from the gas supply unit 3 .

[0102] Figure 12 The main body part 120 of the gas supply part 110 shown has a flat circular shape. Moreover, in the main body part 120, instead of the gas circulation space 32 whose diameter was enlarged in the lower side, the disk-shaped gas circulation space 121 is formed. In addition, the partition members 41 to 46 are not provided in the gas circulation space 121 , and the plate-shaped member 111 is provided on the downstream end 121 a side of the gas circulation space 121 .

[0103] Annular slits 112 divided into four in the circumferential direction are concentrically formed in the plate-shaped member 111 . Figure 13 (a) is a bottom view of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com