Mass continuous safe production diazomethane reactor and working method thereof

A technology of diazomethane and safe production, which is applied in the direction of chemical methods, chemical instruments and methods, and dissolution of liquids and liquids, which can solve the problems of increasing safety hazards, explosives, explosions, etc., and achieve increased safety and reduced Explosion hazard, simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

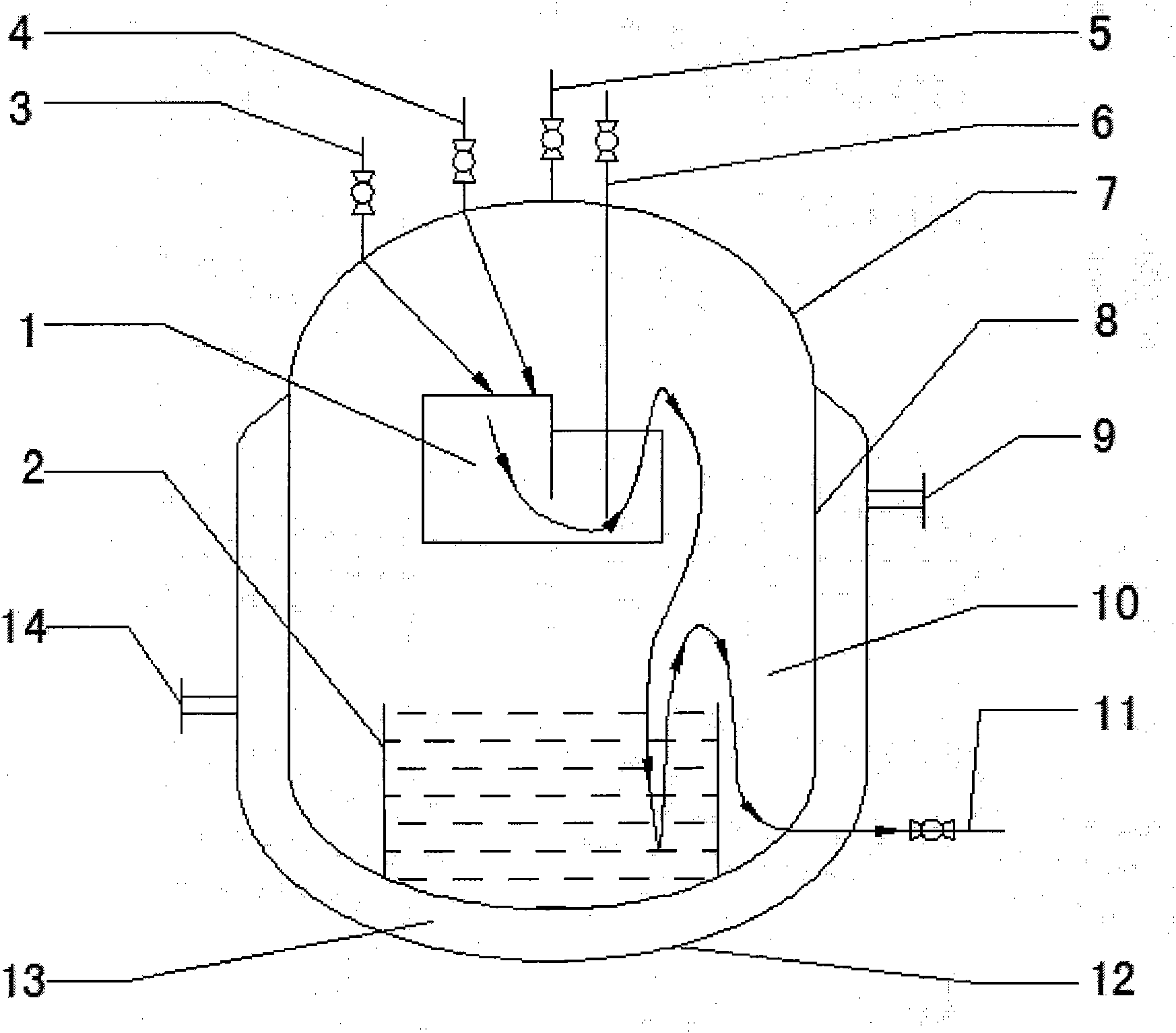

[0028] Embodiment: a kind of large-scale continuous safe production diazomethane reactor and working method thereof (see figure 1 ), is characterized in that by cavity 10, reaction center I1, reaction center II2, raw material A dropping port 3, raw material B dropping port 4, N 2 Air intake bubbling pipe 6, diazomethane outlet pipe 5, cooling jacket 13, cooling medium inlet 14, cooling medium outlet 9, and waste liquid discharge pipe 11.

[0029] The cavity 10 is composed of an upper head 7, a reactor wall 8, and a lower head 12, and the top of the upper head 7 is provided with a raw material A dropping port 3, a raw material B dropping port 4, N 2 Inlet bubbling pipe 6 and diazomethane outlet pipe 5; said reaction center I1 and reaction center II2 are in the cavity 10, wherein the reaction center I1 is located at the upper part of the cavity 10, and the reaction center II2 is located at the bottom of the cavity 10 The reaction center II2 is connected with the lower head 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com