Automatic steel ball casting forming machine

A molding machine and steel ball technology, applied in the direction of casting molding equipment, molding machines, casting molds, etc., can solve the problems of not being able to meet mass production, high labor intensity of workers, poor production efficiency, etc., to meet the requirements of mass production, structure Compactness and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

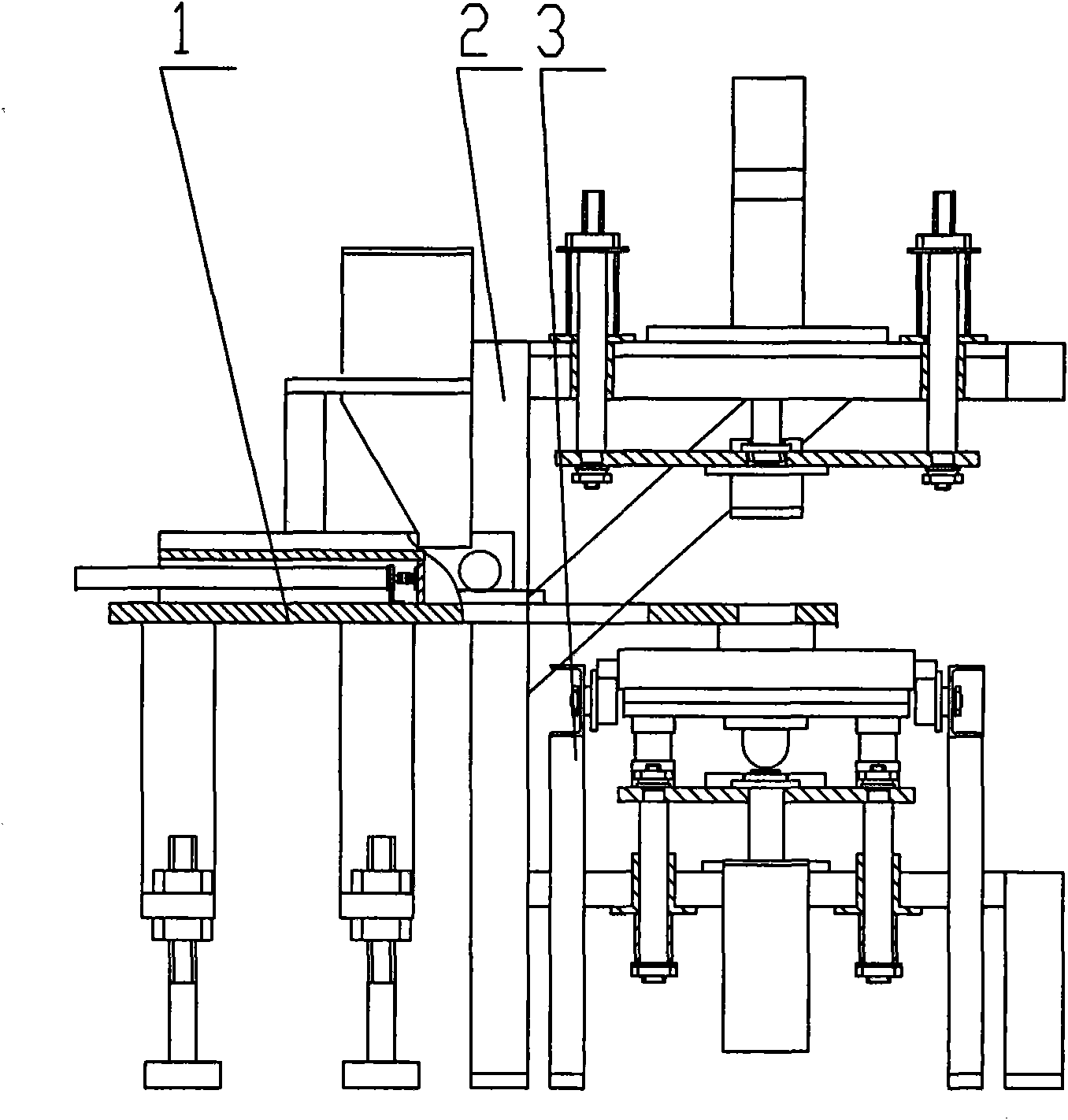

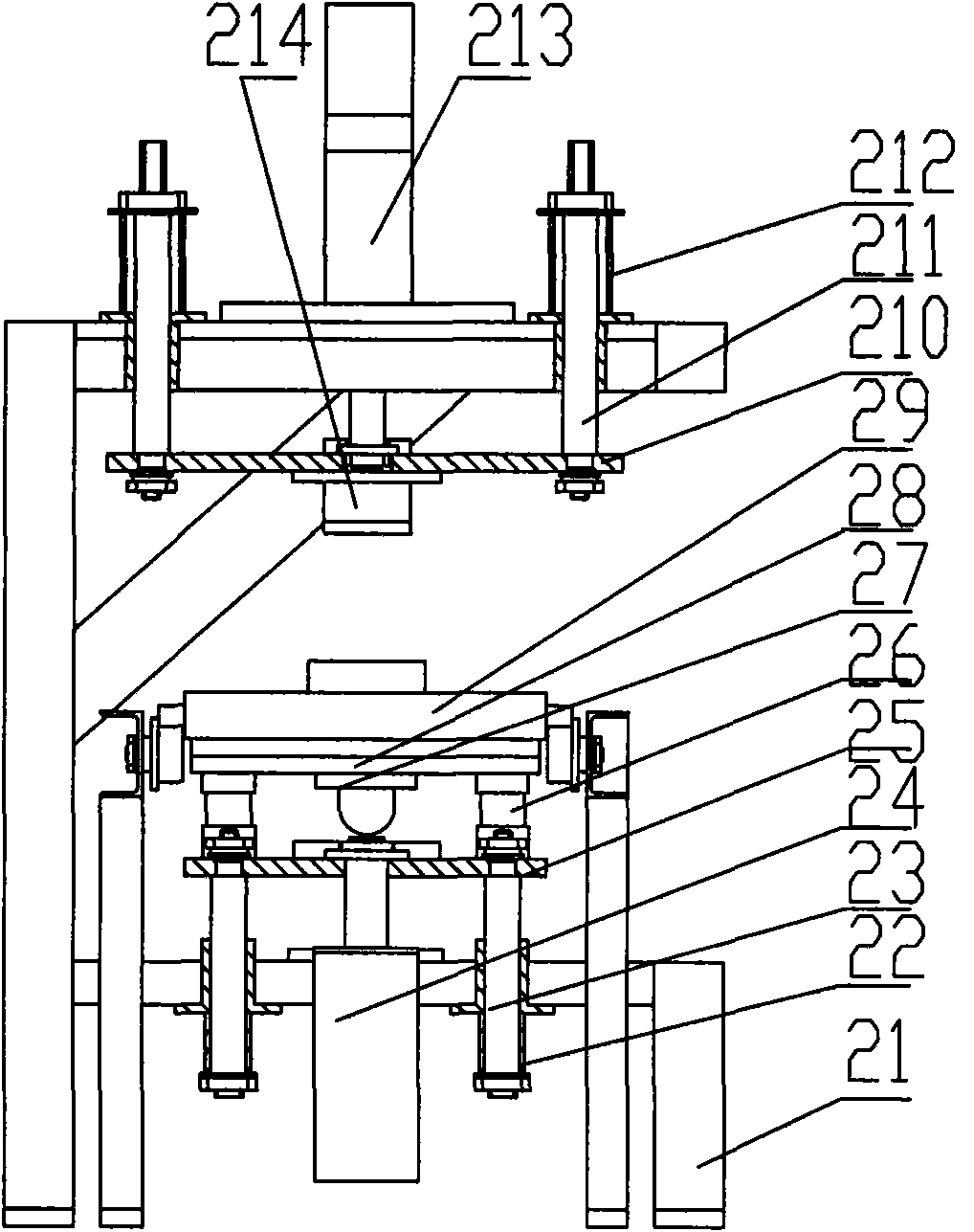

[0018] like figure 1 The automatic steel ball machine shown is composed of a feeder 1, a molding machine 2, and a guide rail 3. The feeder 1 is located at the rear of the molding machine 2, and the mold template 29 is located on the vibration table of the molding machine 2. When forming, the steel ball mold is located on the mold plate 29, and the round mouth of the feeding box bottom plate 13 of the feeder 1 is aligned with the mold plate. When working, the feeder 1 sends the molding sand to the cavity of the mold, and the vibrating table The vibration drives the mold to vibrate, the pressure head 214 presses down to form, and the molding sand is formed in the mold.

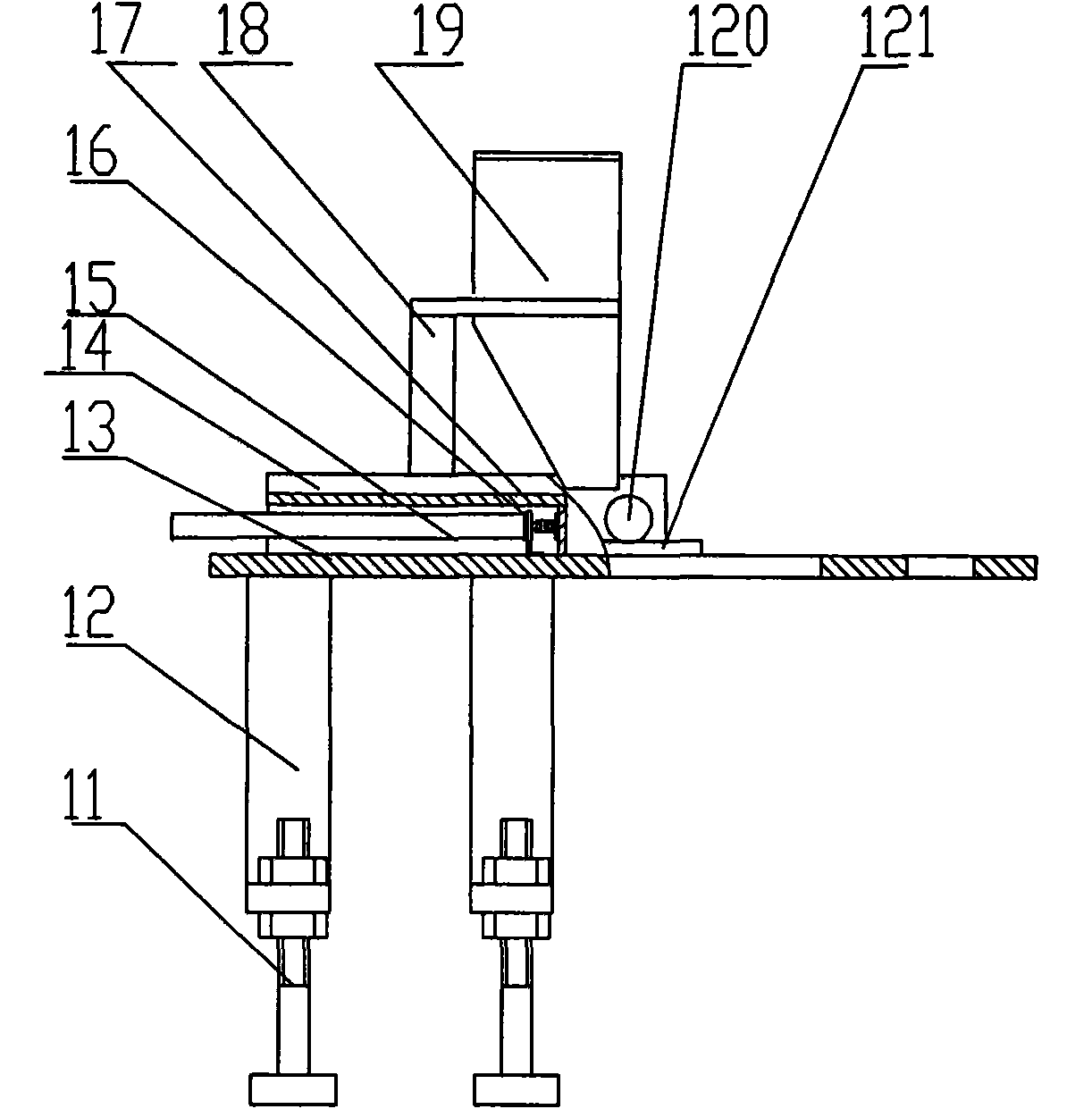

[0019] like figure 2 The shown feeder 1 is mounted on the rear of the molding machine 2, and consists of height adjustment bolts 11, adjustment feet 12, feed box bottom plate 13, feed box 14, telescopic cylinder 15, fixed bracket 16, material partition plate 17, hopper frame 18 , Storage box 19, guide wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com