Method for producing gardenia yellow pigment

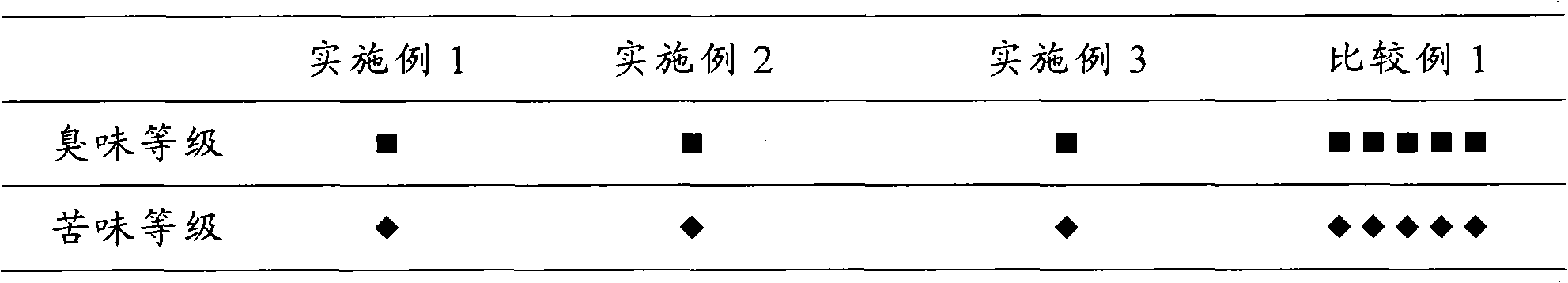

The technology of a gardenia yellow pigment and a production method is applied in the production field of the gardenia yellow pigment, and can solve the problems affecting the application range of the gardenia yellow pigment, and achieve the effects of low bitterness and odor and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dry and crush the gardenia fruit to 10 mesh, put 10kg of gardenia powder into the extraction tank, add 30kg of No. 6 extraction solvent oil, extract at 25°C for 60 minutes, filter, collect the filter residue, and repeat the above operation for the filter residue Carry out leaching again and collect filter residue;

[0033] Take 5 kg of the filter residue obtained in the previous step and put it into an extraction tank, add 20 kg of ethanol solution with a volume concentration of 60% to the filter residue and extract it at 25°C for 120 minutes, collect the filter residue and filtrate after filtering, repeat the above operation for the filter residue and then perform two leaching Extracting, combining the filtrate obtained after three extractions, and vacuum concentrating at 55°C under a vacuum degree of -0.08Mpa to obtain the first pigment concentrate;

[0034] Dilute the first pigment concentrate obtained in the previous step with 4 times the volume of deionized water a...

Embodiment 2

[0037]Dry and crush the gardenia fruit to 6 mesh, put 10kg of gardenia powder into the extraction tank, add 12kg of No. 6 extraction solvent oil, extract at 45°C for 60 minutes, filter, collect the filter residue, and repeat the above operation for the filter residue Carry out leaching again and collect filter residue;

[0038] Take 5kg of the filter residue obtained in the previous step and put it into the extraction tank, add 20kg of ethanol solution with a volume concentration of 45% to the filter residue and extract it at 20°C for 70min, collect the filter residue and filtrate after filtration, repeat the above operation for the filter residue and then extract again , combining the filtrates obtained after two leachings, and vacuum-concentrating at 50°C under a vacuum degree of -0.07Mpa to obtain the first pigment concentrate;

[0039] Dilute the first pigment concentrate obtained in the previous step with 4 times its volume of deionized water and apply it to D101 macropor...

Embodiment 3

[0042] Dry and crush the gardenia fruit to 15 mesh, take 10kg of gardenia powder and put it into the extraction tank, add 55kg of No. 6 extraction solvent oil, extract at 45°C for 150min, filter, collect the filter residue, and repeat the above operation for the filter residue Carry out leaching again and collect filter residue;

[0043] Take 5kg of the filter residue obtained in the previous step and put it into the extraction tank, add 20kg of ethanol solution with a volume concentration of 60% to the filter residue and extract it at 25°C for 150min, collect the filter residue and filtrate after filtration, repeat the above operation for the filter residue and then carry out leaching again , combining the filtrates obtained after two leachings, and vacuum-concentrating at 70°C under a vacuum degree of -0.08Mpa to obtain the first pigment concentrate;

[0044] Dilute the first pigment concentrate obtained in the previous step with 4 times its volume of deionized water and app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com