Components of armyworm adhesive and method for preparing same

An adhesive and armyworm technology, which is applied in the directions of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of poor control effect of male Liriomyza sativa and poor stickiness of pests, and achieves remarkable control effect, strong selectivity, Environmentally compatible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

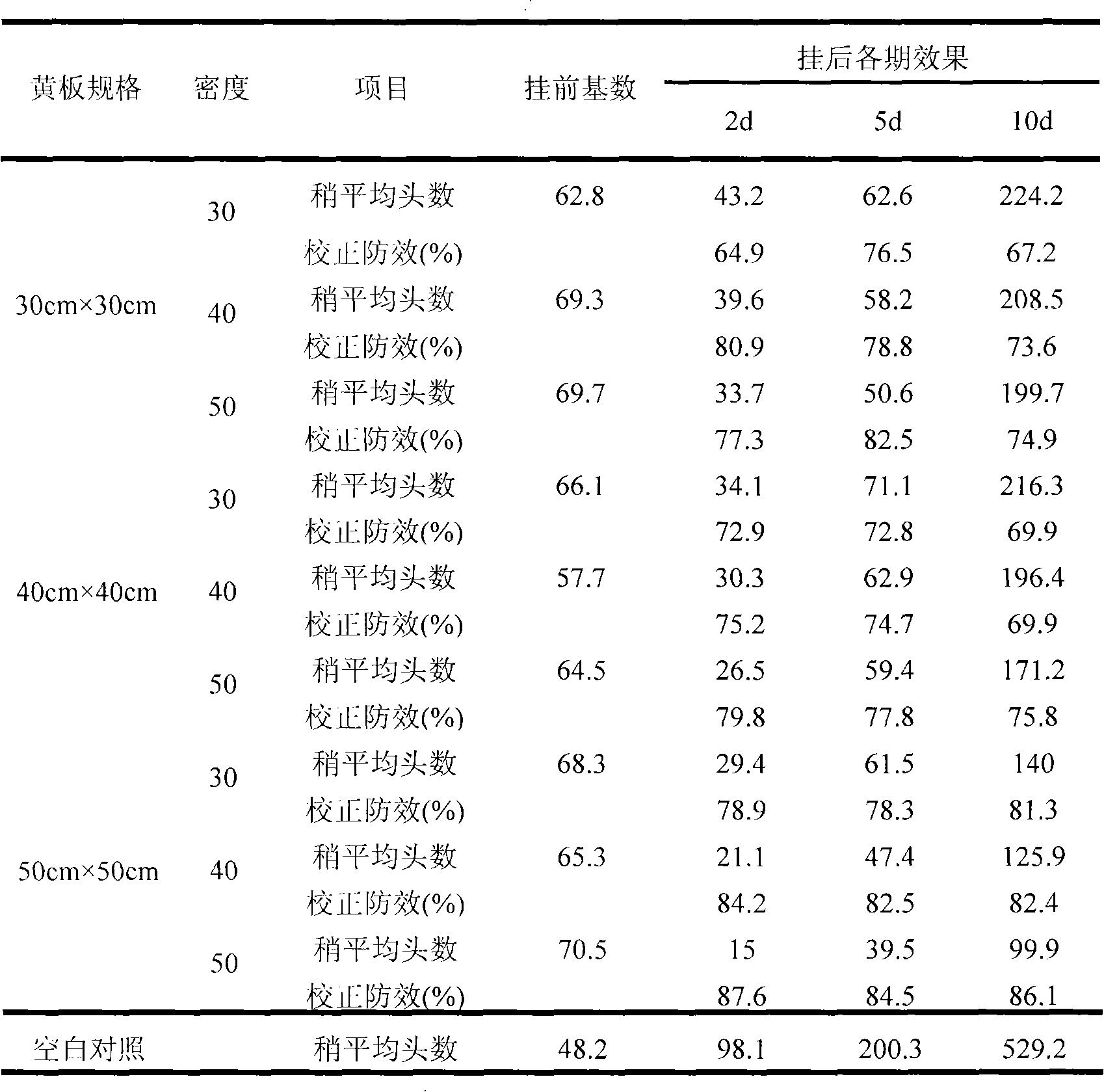

Image

Examples

Embodiment 1

[0028] Armyworm adhesive, its components and the mass ratio of each component are as follows:

[0029] 36 parts of EVA (ethylene-vinyl acetate);

[0030] CSM (chlorosulfonated polyethylene) 15 parts;

[0031] 8 parts of polymerized rosin;

[0032] 8 parts of hydrogenated rosin;

[0033] 3 parts of anti-aging agent D;

[0034] 14 parts of mineral oil;

[0035] 8 parts Vaseline;

[0036] Kaolin 8 parts.

[0037] The preparation method of this armyworm adhesive comprises the following steps:

[0038] 1) After adding mineral oil, heat it to 130°C, add EVA and CSM in proportion, and then stir evenly until fully dissolved;

[0039] 2) Add polymerized rosin and hydrogenated rosin, stir evenly, and after fully dissolving, vacuumize until there are no bubbles;

[0040] 3) Cool down to 70°C, then add anti-aging agent and Vaseline;

[0041] 4) Add kaolin at last and keep warm until there are no air bubbles in the adhesive.

Embodiment 2

[0043] Armyworm adhesive, its components and the mass ratio of each component are as follows:

[0044] 40 parts of EVA (ethylene-vinyl acetate);

[0045] 20 parts of CSM (chlorosulfonated polyethylene);

[0046] 6 parts of polymerized rosin;

[0047] 6 parts of hydrogenated rosin;

[0048] Antiaging agent D 2 parts;

[0049] 15 parts of mineral oil;

[0050] 5 parts Vaseline;

[0051] Kaolin 6 parts.

[0052] The preparation method of this armyworm adhesive comprises the following steps:

[0053] 1) After adding mineral oil, heat it to 140°C, add EVA and CSM in proportion, and then stir evenly until fully dissolved;

[0054] 2) Add polymerized rosin and hydrogenated rosin, stir evenly, and after fully dissolving, vacuumize until there are no bubbles;

[0055] 3) Cool down to 80°C, then add anti-aging agent and Vaseline;

[0056] 4) Add kaolin at last and keep warm until there are no air bubbles in the adhesive.

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is that the mass ratios of the various components of the armyworm adhesive are different.

[0059] Armyworm adhesive, its components and the mass ratio of each component are as follows:

[0060] 35 parts of EVA (ethylene-vinyl acetate);

[0061] CSM (chlorosulfonated polyethylene) 15 parts;

[0062] 8 parts of polymerized rosin;

[0063] 8 parts of hydrogenated rosin;

[0064] 3 parts of anti-aging agent D;

[0065] 14 parts of mineral oil;

[0066] 8 parts Vaseline;

[0067] Kaolin 9 parts.

[0068] The preparation method of this armyworm adhesive comprises the following steps:

[0069] 1) After adding mineral oil, heat it to 130°C, add EVA and CSM in proportion, and then stir evenly until fully dissolved;

[0070] 2) Add polymerized rosin and hydrogenated rosin, stir evenly, and after fully dissolving, vacuumize until there are no bubbles;

[0071] 3) Cool down to 70°C, then add anti-aging agent and Vase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com