Composite coated bearing shell

A composite coating and bearing pad technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low anti-fatigue strength of the anti-friction layer and the urgent need to improve the anti-fatigue strength, so as to achieve comprehensive performance improvement, enhanced hardness, resistance to fatigue, etc. Excellent corrosive effect

Active Publication Date: 2010-09-29

GUANGZHOU ANDA AUTOMOBILE PARTS

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

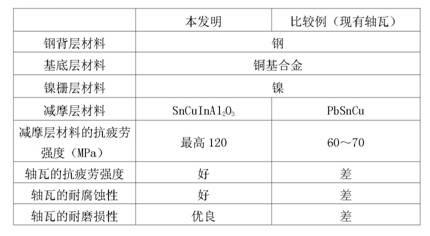

This kind of bearing pad can meet the basic requirements of the engine to a certain extent, but it is applied to the strengthened internal combustion engine. Due to the low fatigue resistance of the anti-friction layer, it cannot meet the development needs of the automotive internal combustion engine. The fatigue resistance, corrosion resistance and Wear resistance needs to be improved urgently

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0024] The ratio of each element in tin-copper-indium oxide aluminum alloy is: copper 0.7%, indium 20%, aluminum oxide 1.5%, and the rest is tin.

Embodiment 2

[0026] The ratio of each element in tin-copper-indium oxide aluminum alloy is: copper 0.7%, indium 2%, aluminum oxide 1%, and the rest is tin.

Embodiment 3

[0028] The proportion of each element in tin copper indium oxide aluminum alloy is: copper 5%, indium 20%, aluminum oxide 0.5%, and the rest is tin.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

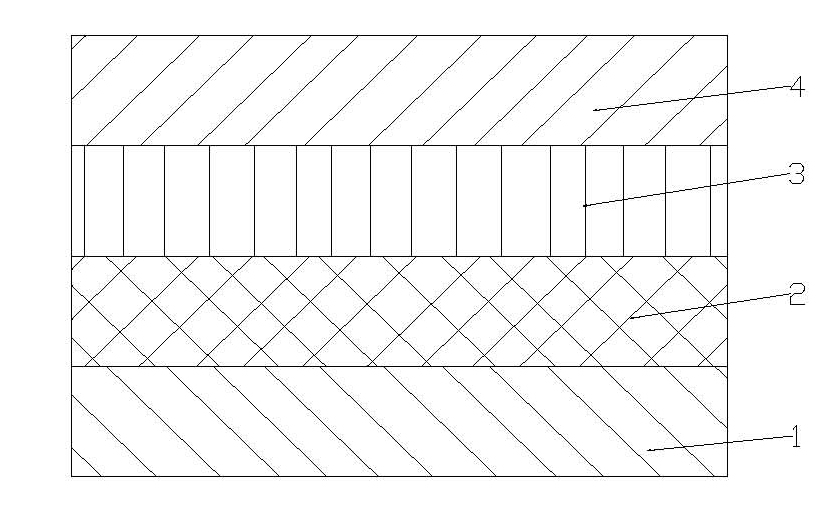

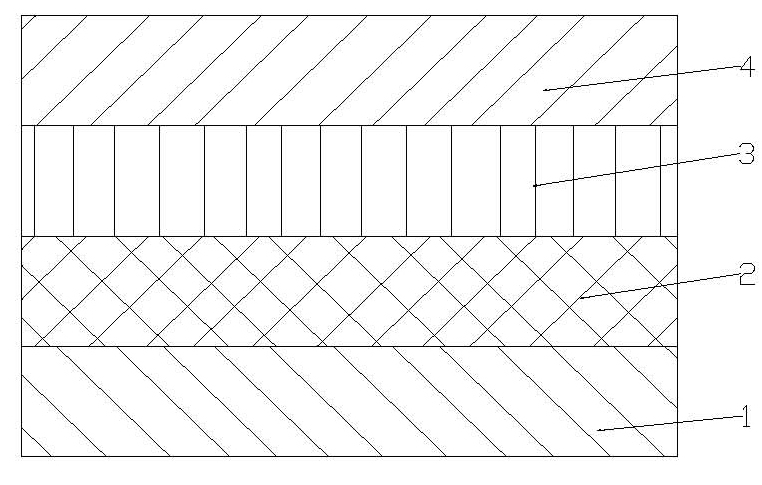

The invention discloses a composite coated bearing shell which comprises a steel backing layer, a basal layer, a nickel grid layer and an antifriction layer which are sequentially arranged. The composite coated bearing shell is characterized in that the antifriction layer is made of tin-copper-indium-aluminum oxide alloy, wherein the tin-copper-indium-aluminum oxide alloy comprises the following elements by proportion: 0.7-5% of copper, 2-20% of indium, 0.5-1.5% of aluminum oxide and the balance of tin. The composite coated bearing shell has the advantages of high bearing, wear resistance, seizure resistance, good embedding performance and corrosion resistance, no lead, environment friendliness and the like.

Description

technical field [0001] The invention relates to the sliding bearing technology of an internal combustion engine, in particular to an improvement technology for a bearing bush of a high-load bearing sliding bearing, and in particular to a composite coating bearing bush. [0002] Background technique [0003] With the development of internal combustion engines in the direction of high speed and high load, the requirements for the performance of bearing pads are constantly increasing. It is required that the bearing pads not only have high load capacity and fatigue resistance, but also have good wear resistance and corrosion resistance. While the comprehensive performance requirements of the bearing bush are improved, more and more attention is paid to the issue of environmental protection. [0004] Traditional copper alloy bearing bushes are currently widely used in high-load internal combustion engines. In terms of structure, they consist of a steel back layer, a copper allo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C33/06F16C33/12

Inventor 刘会学

Owner GUANGZHOU ANDA AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com