High-speed breather valve for oil tanker

A breathable valve, high-speed technology, used in safety valves, balance valves, valve devices, etc., can solve problems such as easy valve opening and gas loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

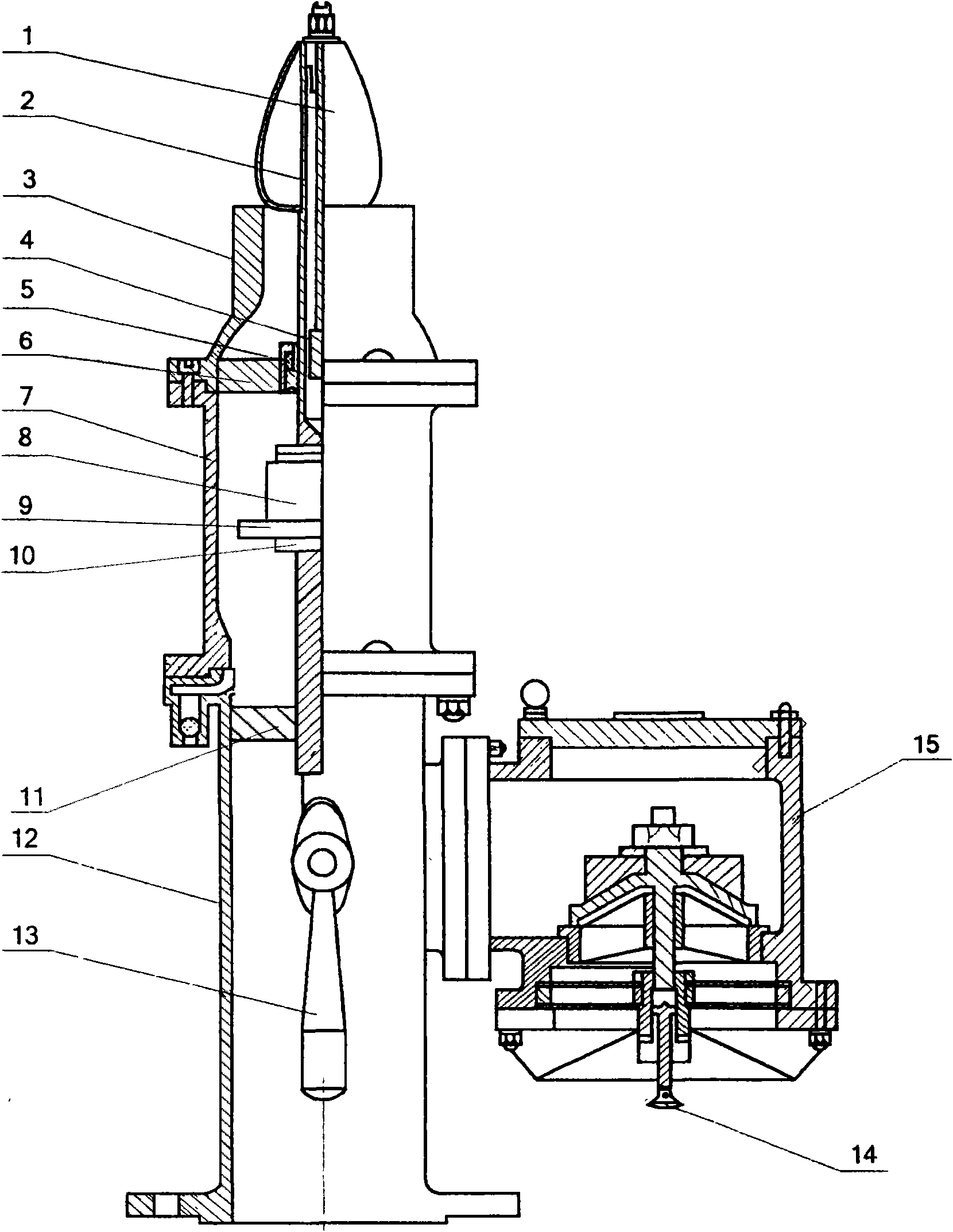

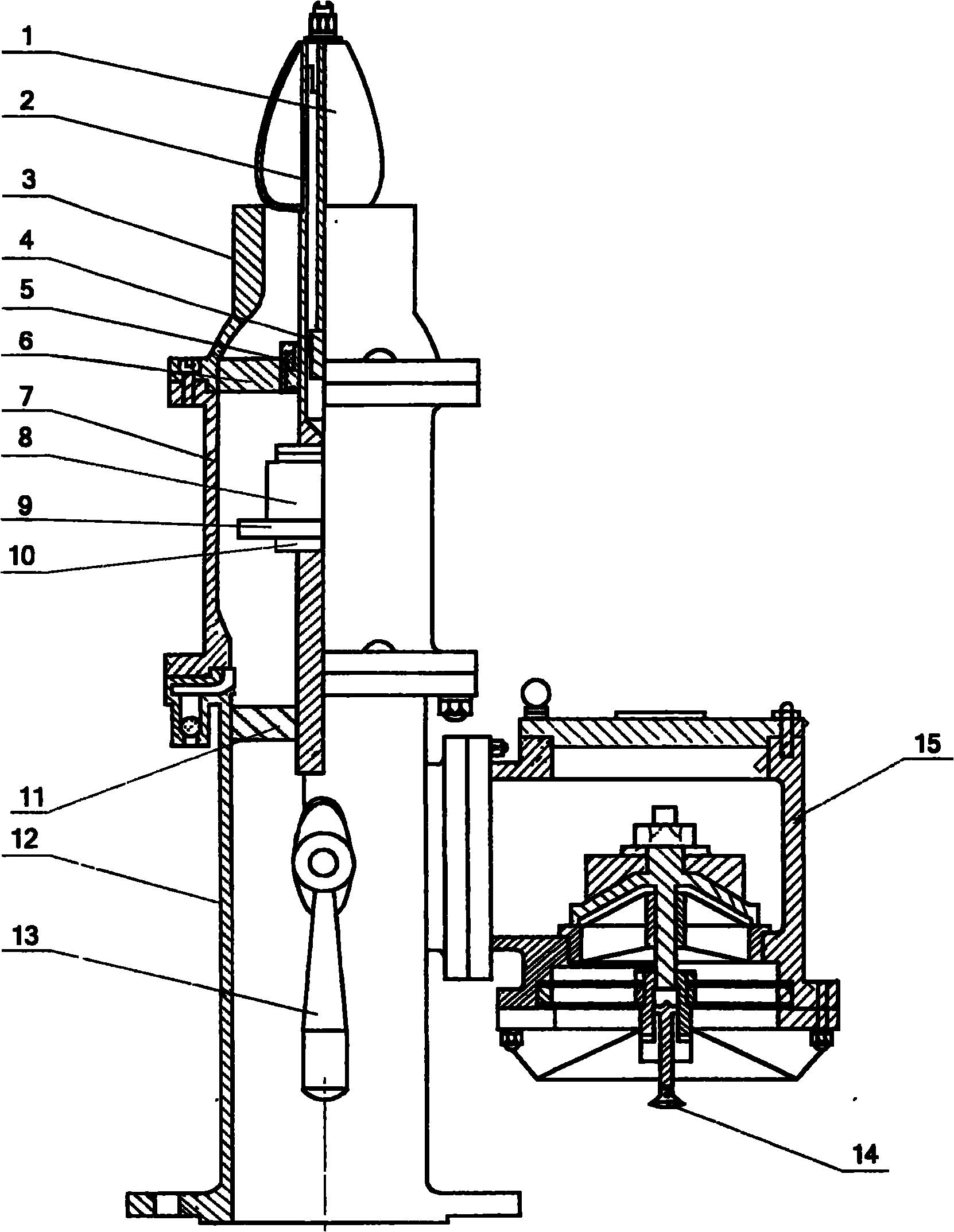

[0010] Such as figure 1 The shown high-speed venting valve for oil tankers mainly includes a pressure valve, a vacuum valve 15, and a deflector 1. The vacuum valve 15 is connected to the side of the three-way lower valve body 12 of the pressure valve. The pressure valve is composed of a three-stage series connection of a guide body 3, an upper valve body 7, and a three-way lower valve body 12. A valve stem 2 is placed in the upper valve body 7 and the cavity of the guide body 3, and its top protrudes from the guide body 3 and is fixedly connected to the guide device 1. The valve stem 2 is equipped with a magnetic adjustment rod 4, and the cavity of the guide body 3 is equipped with There is a permanent magnet ring 5 set on the valve stem 2 and corresponding to the magnetic adjustment rod 4. The permanent magnet ring 5 is fixed by the upper fixed wing 6 fixed in the cavity of the guide body 3. The lower part of the valve stem 2 is connected to the weight 8 and the damping Shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com