Steam supply system for steam air heater of utility boiler

A technology of steam supply system and power station boiler, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of high operating cost, unrecovered working medium, and high quality of steam supply for air heaters. The effect of improving the heat recovery efficiency and reducing the operating cost of power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

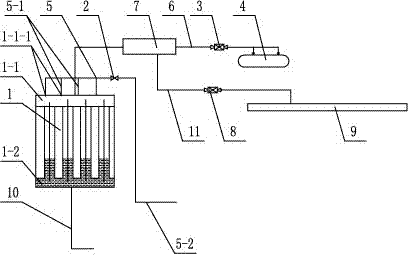

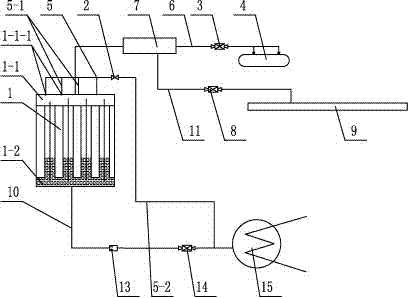

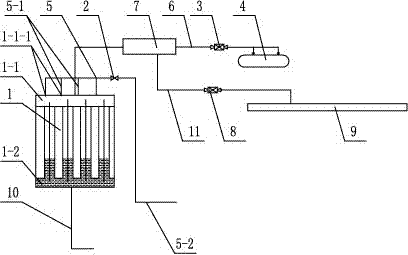

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, a steam supply system for a utility boiler heater in this embodiment includes a heater 1, a deaerator exhaust valve 3, a deaerator 4, a steam supply pipe 6 and a drain pipe 10, the heater The steam inlet header 1-1 of the fan 1 communicates with the deaerator 4 through the steam supply pipe 6, and the deaerator exhaust valve 3 is installed on the steam supply pipe 6, and the drain header of the air heater 1 Drain pipe 10 is installed on 1-2.

[0011] The air heater 1 is a finned air heater, a finned air heater or a bare tube air heater, which is the prior art. This embodiment is especially suitable for the case where the maximum pressure of the deaerator is lower than the design pressure of the air heater.

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 This embodiment will be described. The deaerator exhaust valve 3 in this embodiment is a deaerator exhaust regulating valve. Such setting can effectively prevent the air heater 1 from overpressure. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the steam supply system of this embodiment is also added with an exhaust valve 2 and an exhaust pipe 5, and a plurality of exhaust holes are opened on the upper end surface of the steam inlet header 1-1 of the air heater 1 1-1-1, the exhaust pipe 5 is composed of an exhaust main pipe 5-2 and a plurality of exhaust branch pipes 5-1, and one end of each exhaust branch pipe 5-1 is connected with the corresponding exhaust hole 1-1 -1 communicates, and the other end of each exhaust branch pipe 5-1 communicates with the exhaust main pipe 5-2, and the exhaust valve 2 is installed on the exhaust main pipe 5-2. With such arrangement, the air accumulated in the steam inlet header 1-1 will be discharged in time to prevent the heat exchange from being affected. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com