Vertical launching quantum cascade laser structure

A quantum cascade and vertical emission technology, applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as difficult material growth and complex etching processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

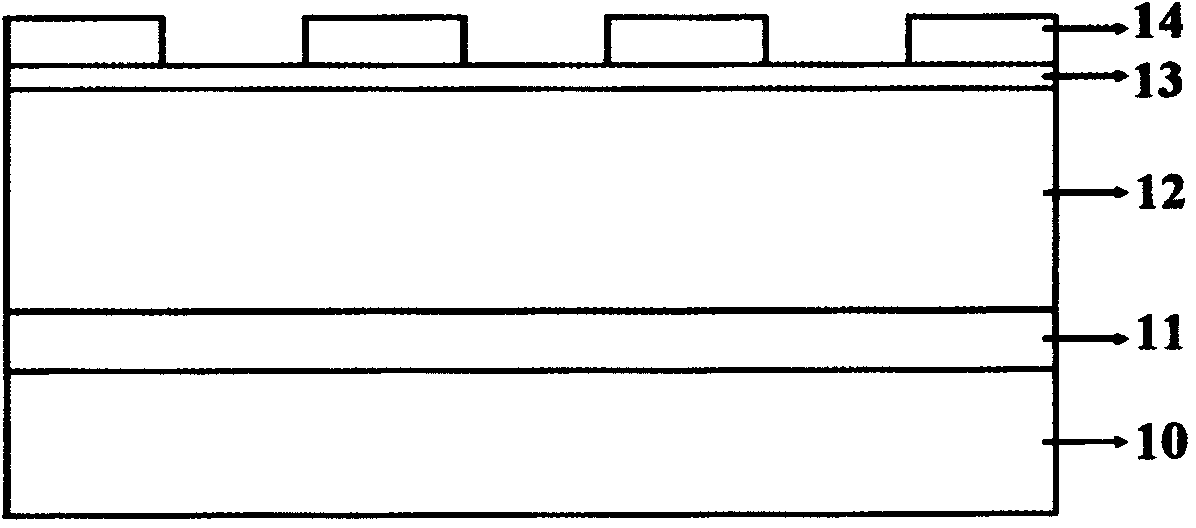

[0020] Please refer to the figure, the present invention provides a vertical emission quantum cascade laser structure, including:

[0021] A substrate 10, on which a waveguide layer 11, an active layer 12 and a contact layer 13 are grown sequentially; the substrate 10 is an InP substrate; the material of the waveguide layer 11 is InGaAs, the The waveguide layer 11 is n-type doped with a doping concentration of 6×10 16 cm -3 , with a layer thickness of 0.55 μm; the active layer 12 is composed of 40 cycles of InGaAs / InAlAs, and the wavelength corresponding to the active layer is 8-12 μm; the material of the contact layer 13 is InGaAs, and the doping concentration is 1×10 19 cm -3 , the layer thickness is 0.05 μm;

[0022] Metal grating layer 14, the metal grating layer 14 is located above the contact layer 13, and the metal grating layer 14 has a second-order Bragg period; the material of the metal grating layer 14 is silver, and the thickness of the metal grating layer 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com