Continuous waste plastics refining unit

A technology for oil refining equipment and waste plastics, which is used in the petroleum industry and the preparation of liquid hydrocarbon mixtures. The effect of operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

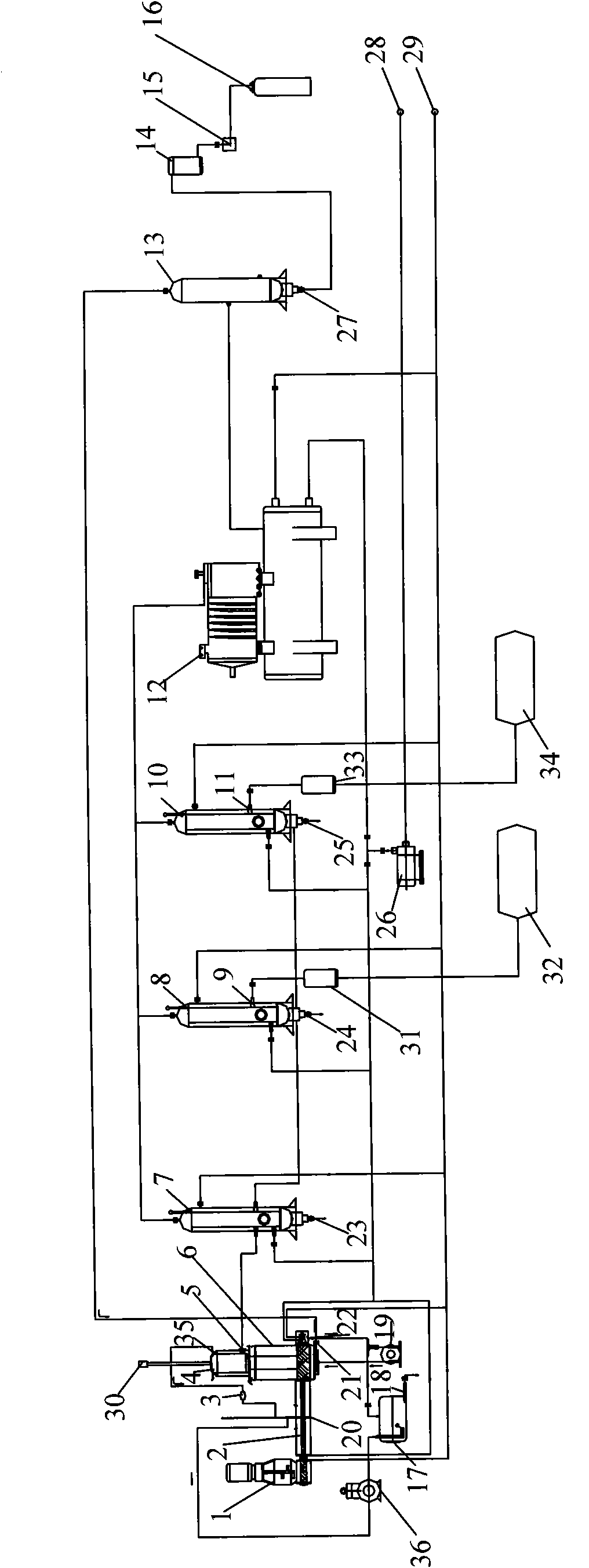

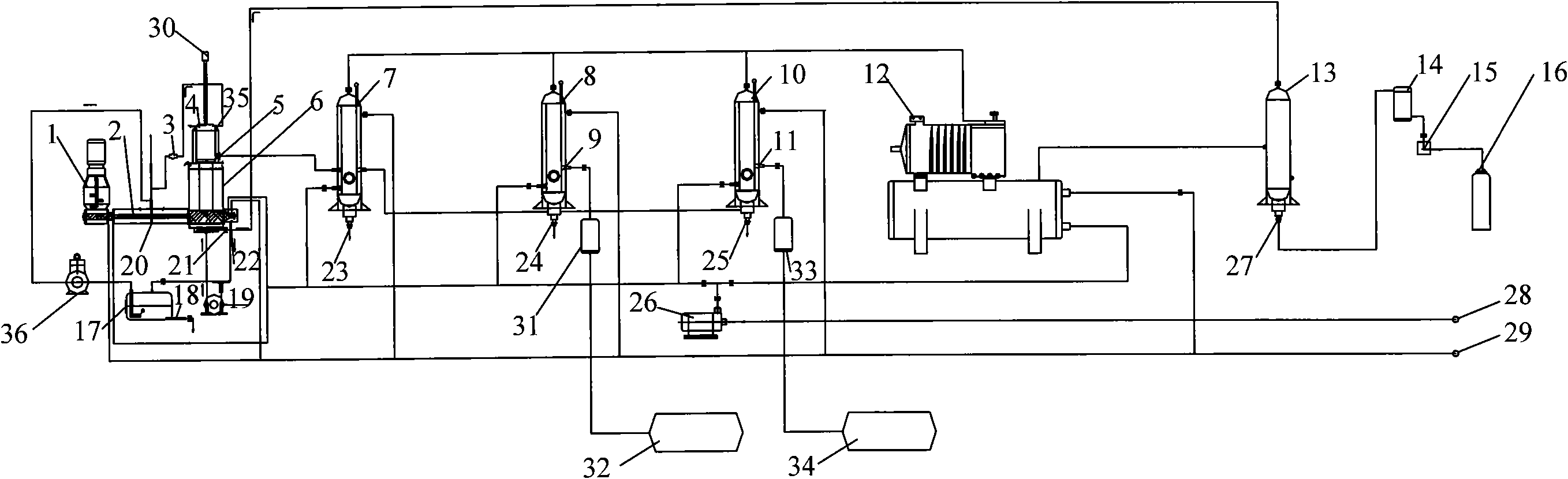

[0009] Such as figure 1 As shown, the continuous type waste plastic refining device of the present invention includes a feeder 1, a feeding screw propeller 2, a safety valve 3, a catalytic tank 4, an oil and gas outlet 5, a cracker 6, an intermediate condenser 7, and a gasoline distillation tank 8 , gasoline outlet 9, diesel rectification tank 10, diesel oil outlet 11, compressor 12, first gas storage tank 13, first filter 14, air release valve 15, second gas storage tank 16, bubbling chamber 17, hydrochloric acid Discharge port 18, fan 19, dechlorinator 20, burner air inlet 21, slag discharge port 22, first water discharge port 23, second water discharge port 24, heavy oil discharge port 25, water pump 26, liquefied gas outlet 27, cooling Water inlet 28, cooling water outlet 29, exhaust pipe 30, second fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com