Process for improving fermentation conversion rate of enzyme preparation

A technology of enzyme preparation and conversion rate, which is applied in the field of biochemistry, can solve problems such as the inability to fully meet the needs of large-scale production of enzyme preparations, and achieve the effects of improving energy utilization, ensuring aerobic demand, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

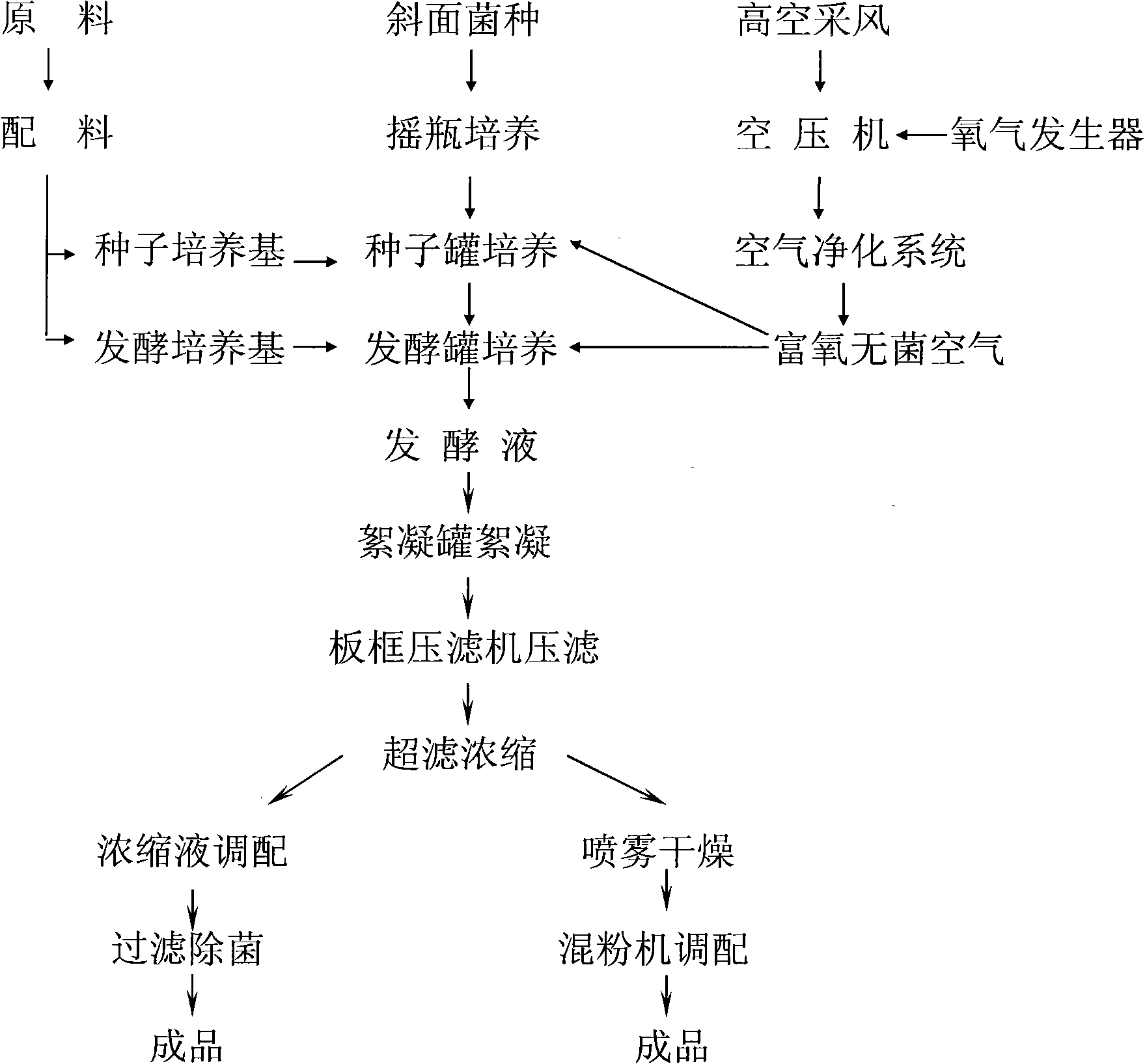

Image

Examples

Embodiment Construction

[0012] The present invention will be further described by taking the production of glucoamylase by Aspergillus niger as an example below.

[0013] Slant medium: 30g sucrose, NaNO 3 2g, K 2 HPO 4 1g, KCl 0.5g, magnesium sulfate heptahydrate 0.5g, ferrous sulfate heptahydrate 0.01g, agar 20g, distilled water 1000ml, natural pH.

[0014] Shake flask medium: glucose 100g, bean cake powder 30g, corn steep liquor 30g, distilled water 1000ml, natural pH.

[0015] Seed medium: 180g cornstarch, 30g bean cake powder, 30g corn syrup, 1000ml distilled water, natural pH.

[0016] Fermentation medium: 30% corn starch, 4% bean cake powder, 4% corn steep liquor, (NH 4 ) 2 SO 4 0.5%, natural pH.

[0017] First culture the strain on the slope of the slant medium at 33°C for 96h, then insert it into the shake flask containing the shake flask medium and cultivate it at 30°C for 48h, then insert it into the seed culture tank containing the seed medium at 32°C, 240rpm Cultivate for 48h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com