Method for improving fermentation conversion rate of enzyme preparation by utilizing oxygen partial pressure

An enzyme preparation and conversion rate technology, applied in the field of biochemistry, can solve problems such as the inability to fully meet the needs of large-scale production of enzyme preparations, and achieve the effects of improving energy utilization, increasing production, and ensuring oxygen demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

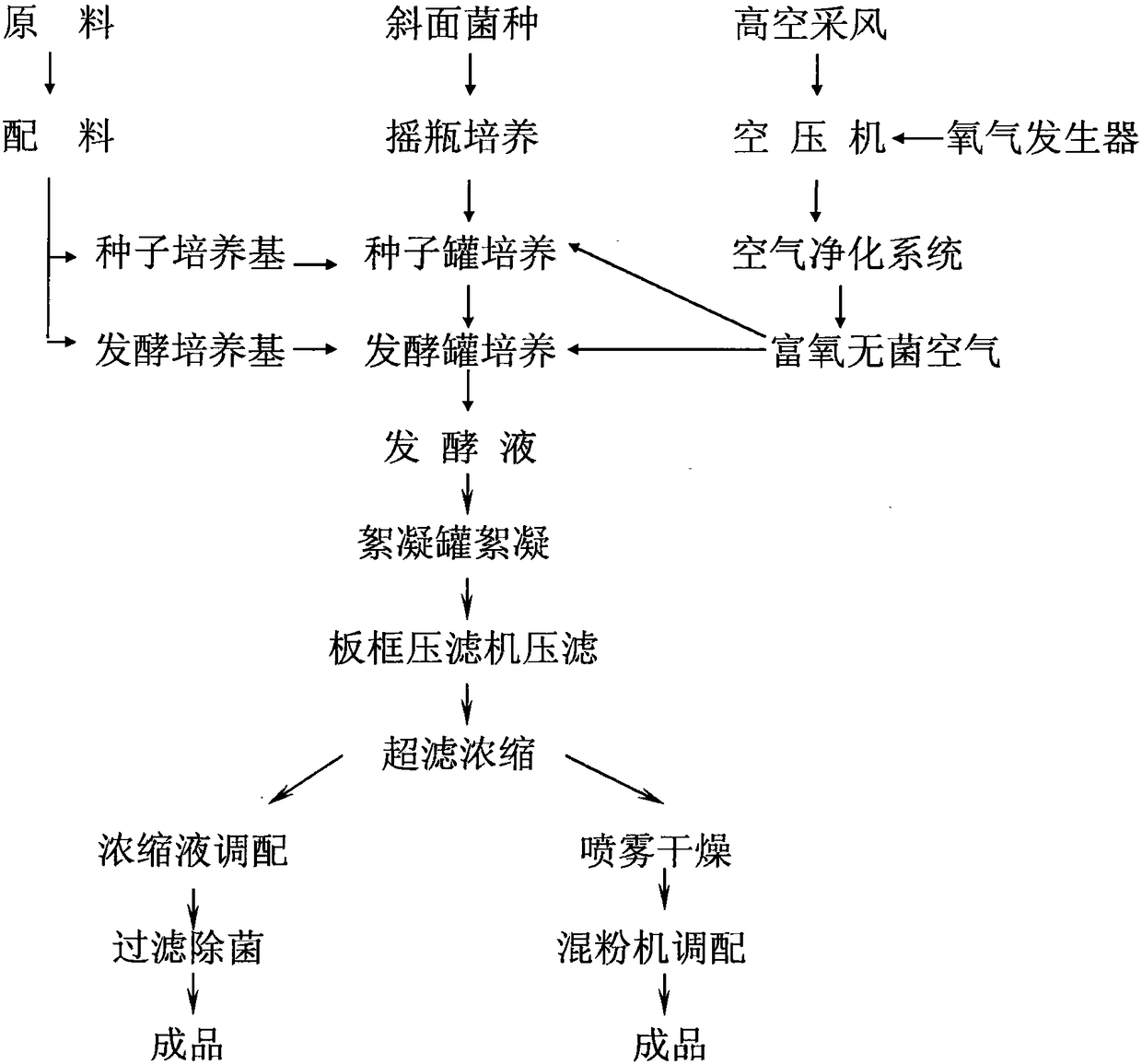

Image

Examples

Embodiment Construction

[0012] The present invention will be further described by taking the production of glucoamylase by Aspergillus niger as an example below.

[0013] Slant medium: 30g sucrose, 32g NaNO, 41g K2HPO, 0.5g KCl, 0.5g magnesium sulfate heptahydrate, 0.01g ferrous sulfate heptahydrate, 20g agar, 1000ml distilled water, natural pH.

[0014] Shake flask medium: glucose 100g, bean cake powder 30g, corn steep liquor 30g, distilled water 1000ml, natural pH.

[0015] Seed medium: 180g cornstarch, 30g bean cake powder, 30g corn syrup, 1000ml distilled water, natural pH.

[0016] Fermentation medium: 30% cornstarch, 4% bean cake powder, 4% corn steep liquor, (NH4)2SO40.5%, natural pH.

[0017] First culture the strain on the slope of the slant medium at 33°C for 96h, then insert it into the shake flask containing the shake flask medium and cultivate it at 30°C for 48h, then insert it into the seed culture tank containing the seed medium at 32°C, 240rpm Cultivate for 48h. The 10% inoculum wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com