Electric roller brush

A rolling brush, electric technology, applied in the direction of construction, building structure, etc., can solve the problems of easy-to-pollute decorative ornaments, low work efficiency, dripping and other problems, and achieve the effect of wide application range, high work efficiency, and simple filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

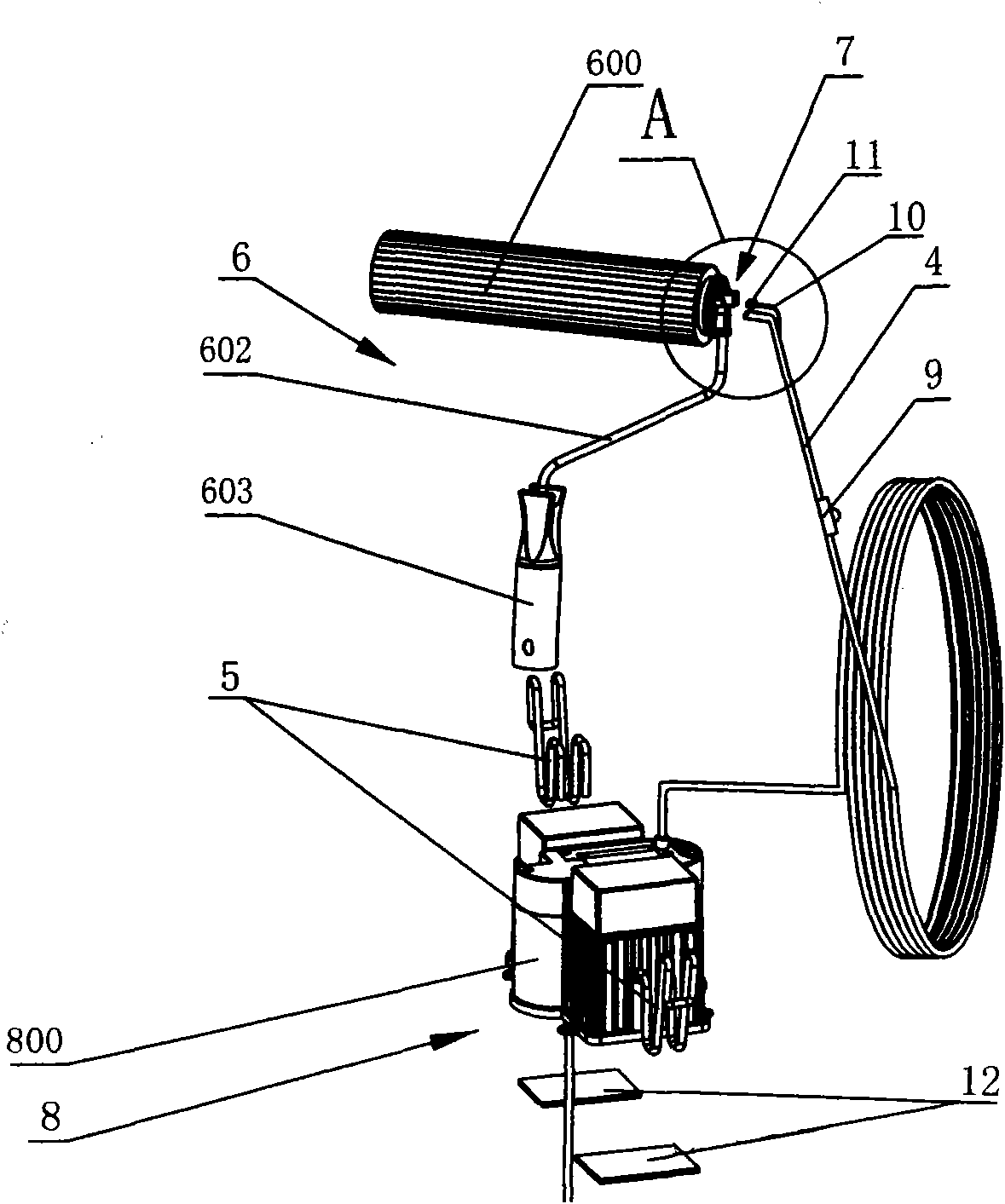

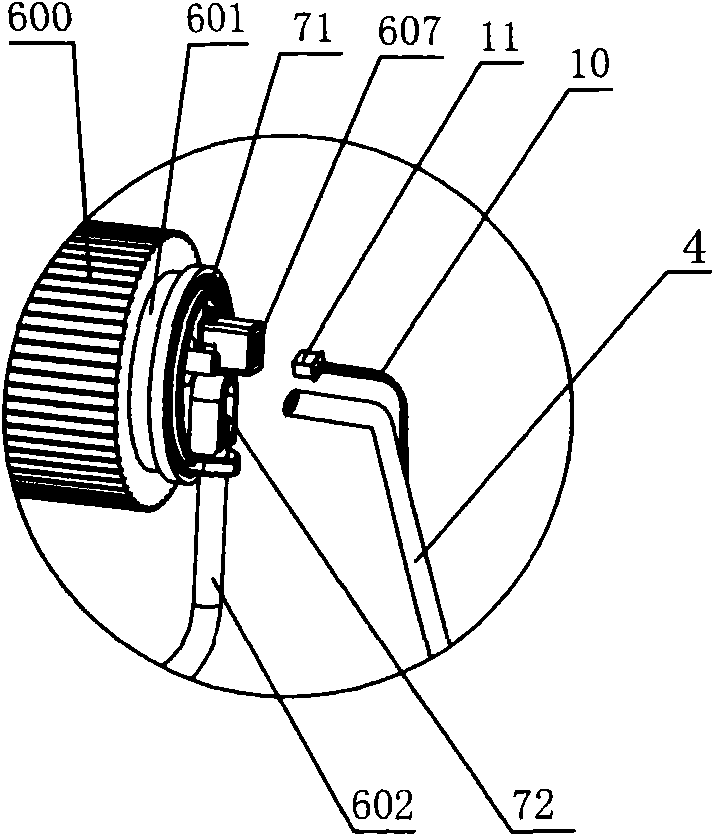

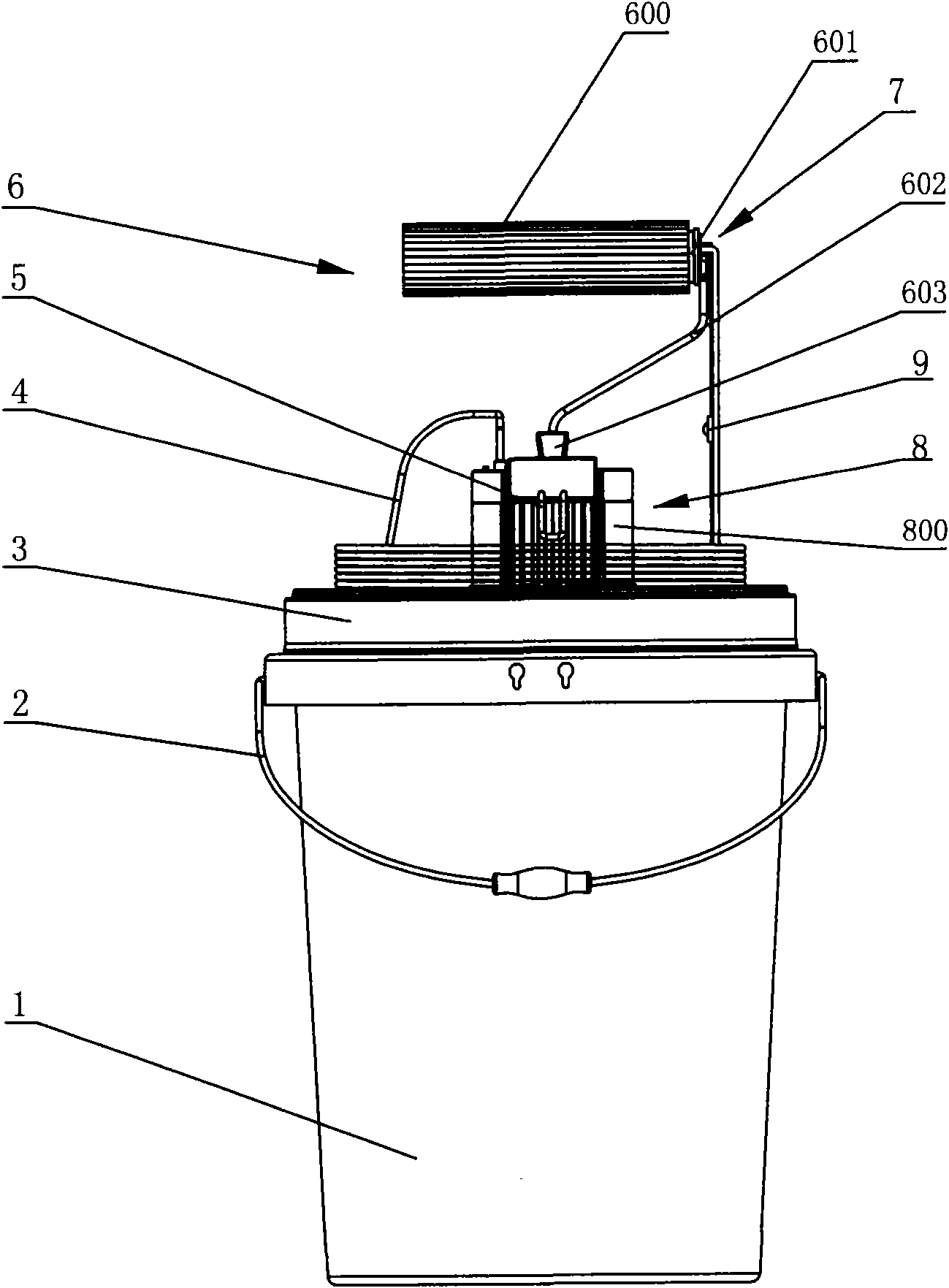

[0035] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings. like Figure 1 ~ Figure 2 As shown in 0, 1. material barrel, 2. lifting ring, 3. barrel cover, 4. feeding pipe, 5. bracket, 6. roller brush, 600. bristle, 601. right roller sleeve, 602. brush rod, 603. Brush handle, 604. Bolt, 605. Limiting ring, 606. Left roller sleeve, 607. Connecting socket, 608. Rib, 609. Filter cover, 610. Drum, 611. Inner ring gear, 612. Left Fixed ring, 613. Discharge pipe, 614. Discharge hole, 615. Support rod, 616. Right fixed ring, 617. Connector, 618. Belt, 619. Gear frame, 7. Switch device, 71. Roller jacket, 72. Groove, 73. Cam, 74. First stage gear, 75. Third stage gear, 76. Second stage gear, 77. Micro switch, 78. Concave edge, 79. Convex edge, 8. Host pump . Wheel slot, 810. Runner, 811. Runner shaft, 812. Pressure tube wheel, 813. Gap, 9. Manual switch, 10. Wire, 11. Plug, 12. Adhesive, 13. Motor, 14. Battery, 15. Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com