Torque measurement device

A torque measurement, stepped shaft technology, applied in the field of torque measurement devices, can solve problems such as poor signal-to-noise ratio, unavoidable errors, and wear of contact parts, achieve simple on-site installation and torque testing operations, reduce on-site work, and avoid testing. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

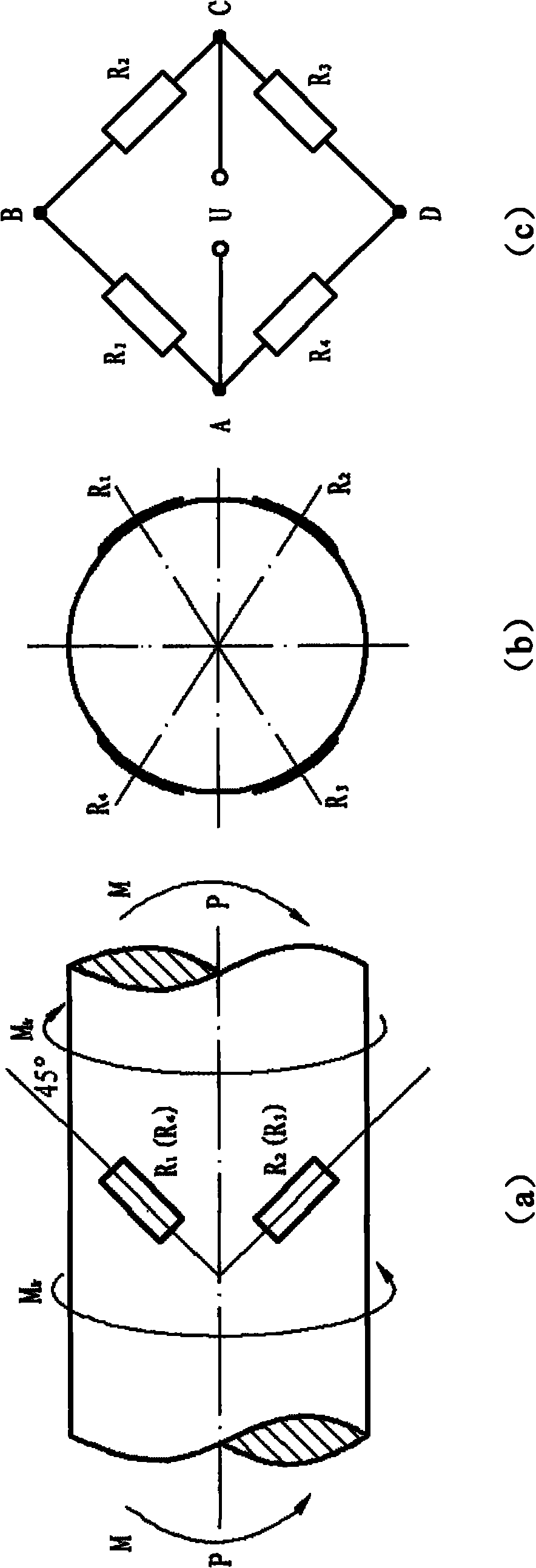

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

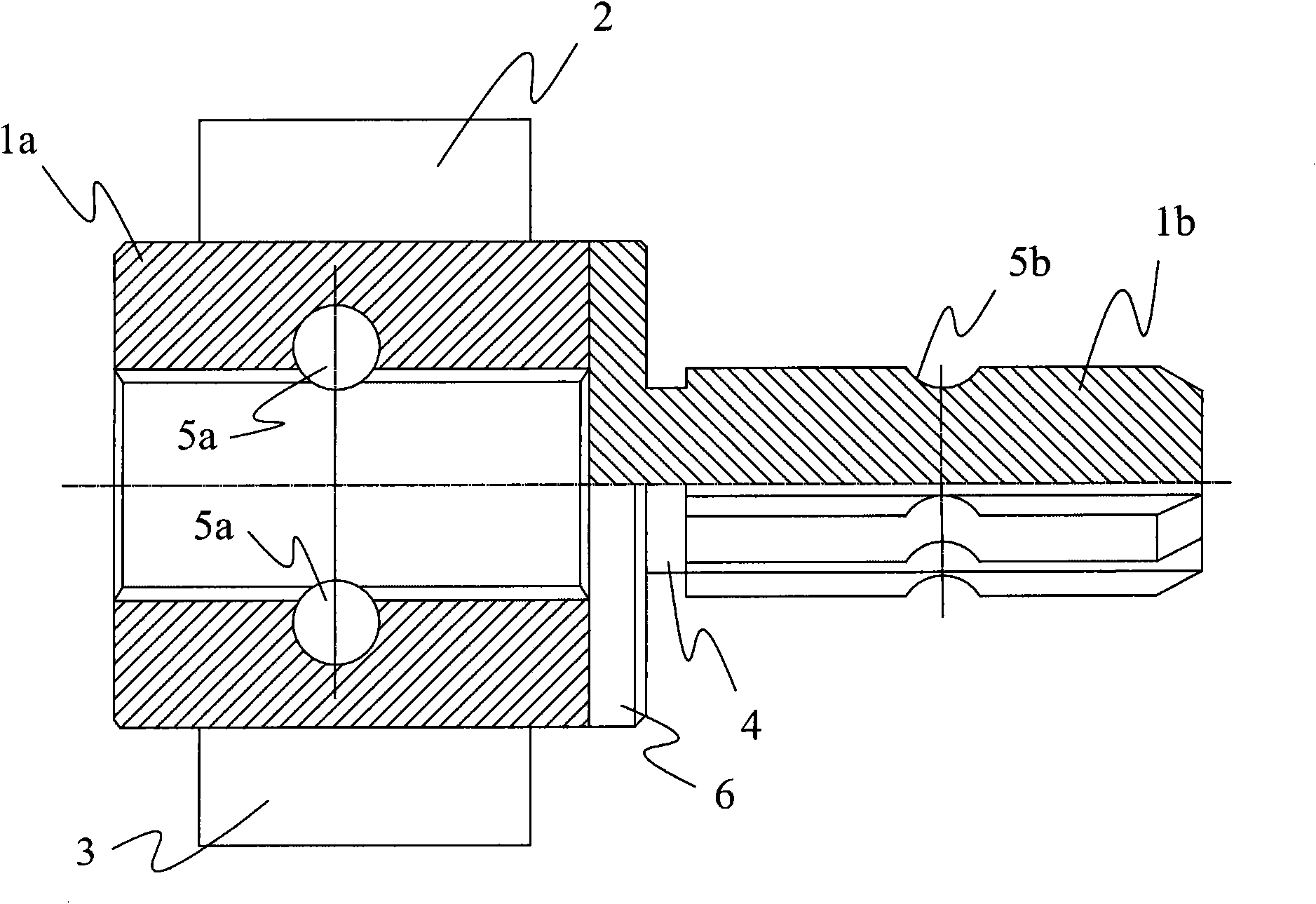

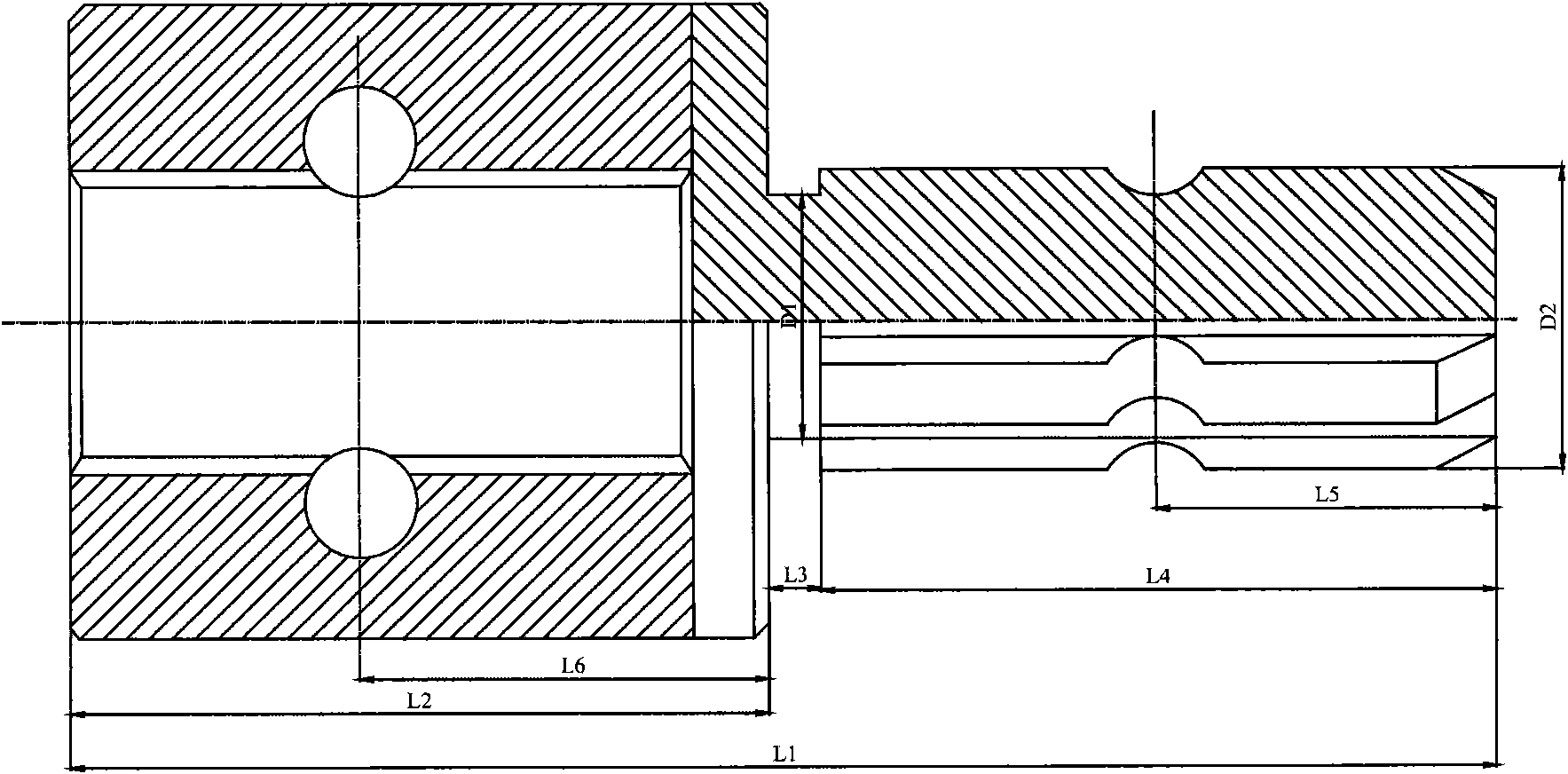

[0029] Such as figure 2 As shown, the torque measuring device of this embodiment comprises: a shaft sleeve 1a, a stepped shaft 1b welded to the shaft sleeve 1a, an inductive element, a wireless transmitting unit and a conditioning unit 2, and a power supply unit 3. The shaft sleeve 1a is a cubic metal body with an internal hollow structure, the hollow structure has internal splines, and the cross-sectional shape of the internal splines matches the cross-sectional shape of the external splines of the power output shaft of the power device to be connected. The height H1 of the inner spline = the outer spline addendum circle diameter φD of the power output shaft of the tractor and other power devices under test EE +(20~30mm); Width B1=Outer spline addendum circle diameter φD of the power output shaft of the tractor and other power devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com