Two-chambered alga microbial fuel cell and treatment wastewater method of low energy consumption thereof

A fuel cell and wastewater treatment technology, applied in biochemical fuel cells, fuel cells, sustainable biological treatment, etc., can solve the problems of high energy consumption and high cost, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

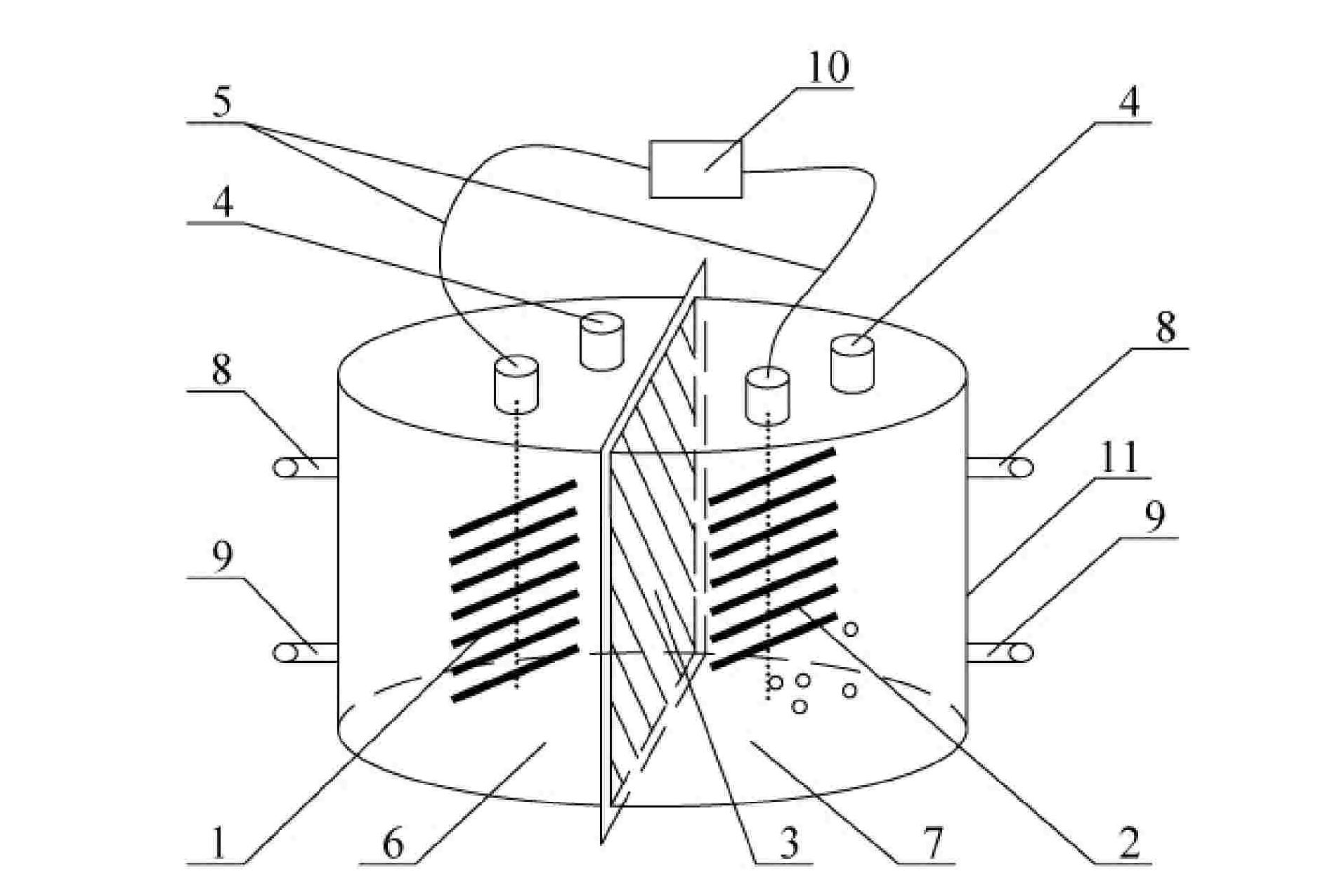

[0014] Embodiment 1: In this embodiment, the double-chamber algae microbial fuel cell consists of an anode 1, a cathode 2, a diaphragm 3, a sampling port 4, an anode chamber 6, a cathode chamber 7, a water inlet 8, a water outlet 9, a casing 11, an outer The circuit 10 and the wire 5 constitute, the anode chamber 6 and the cathode chamber 7 are separated by a diaphragm 3, and a vacuum pad is sandwiched between the diaphragm 3 and the anode chamber 6 and the cathode chamber 7 (to keep the seal), and the anode chamber 6 is provided with Anode 1 and cathode chamber 7 are provided with cathode 2, anode 1 and cathode 2 are connected to external circuit 10 provided outside housing 11 through wire 5, water inlets 8 are respectively opened on the side walls of cathode chamber 7 and anode chamber 6 , and have water outlets 9 respectively at the bottom of the side wall, the cathode chamber 7 is made of plexiglass (to ensure sufficient sunlight), and algae are added in the cathode chamber...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the material of the anode 1 is carbon cloth, carbon paper, carbon felt, carbon brush, activated carbon particles, graphite plate, graphite particle, stainless steel plate, Stainless steel mesh, titanium plate or titanium mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the carbon brushes are pretreated, and the carbon brush pretreatment method is to heat the carbon brushes at 450°C for 30 minutes, and then cool them to room temperature, then soaked in 10% H 2 SO 4 solution for 10 minutes, then neutralized with a 10% NaOH solution, and finally washed with distilled water. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com