Device for removing harmful gas from airflow

A technology of harmful gas and air flow, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of complex adsorbent regeneration and subsequent treatment systems, and the inability to decompose harmful gases, so as to improve energy utilization efficiency, The effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

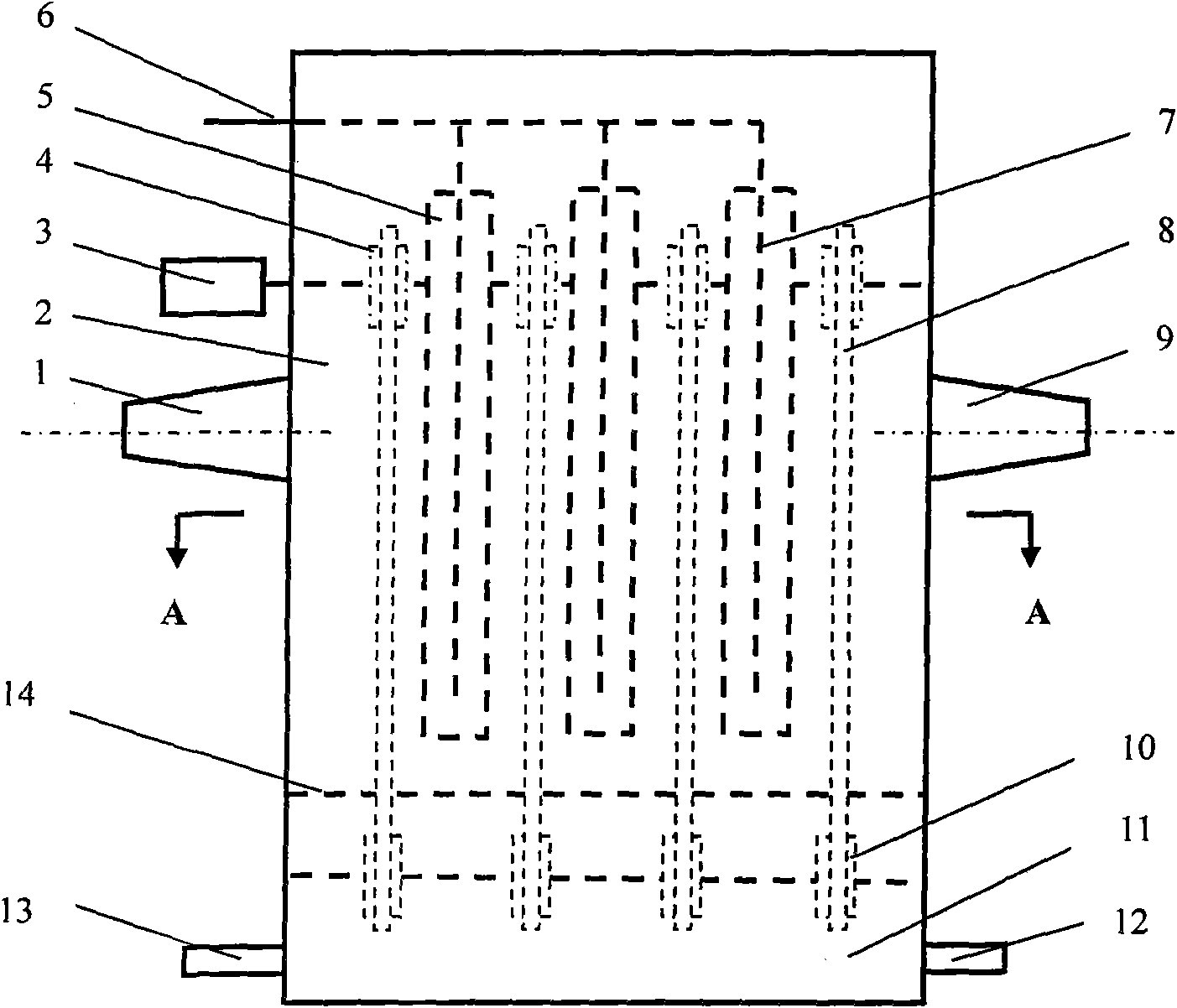

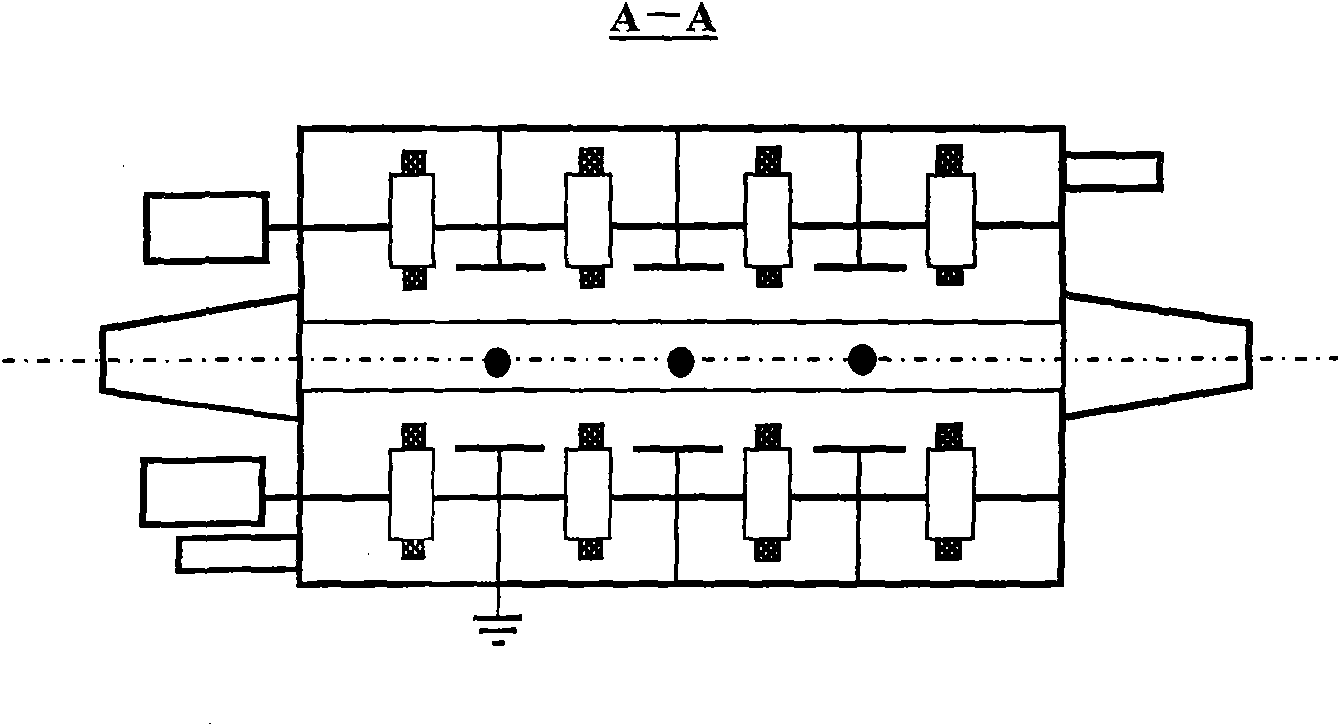

[0019] refer to figure 1 : A purification device for harmful exhaust gas, comprising gas inlet 1, gas circulation space 2, conveyor belt driving motor 3, upper conveyor pulley 4, electrode plate (grounding) 5, corona high voltage wiring 6, corona wire 7, and the surface is for uploading Conveyor belt with absorbent 8, gas outlet 9, lower conveyor pulley 10, absorbent slurry pool 11, absorbent slurry inlet 12, absorbent slurry outlet 13 at the lower part of the device, and partitions between the upper gas circulation space and the absorbent slurry layer 14 apart.

[0020] The treatment process is to introduce the gas containing harmful gas to be treated into the reactor through the gas inlet 1, and the gas flow first passes through the corona discharge area, and under the action of the corona discharge in the reaction area, the harmful gas in the gas flow is oxidized and decomposed. Then in the gas-solid absorption reaction zone, the acidic product in the product reacts with t...

Embodiment 2

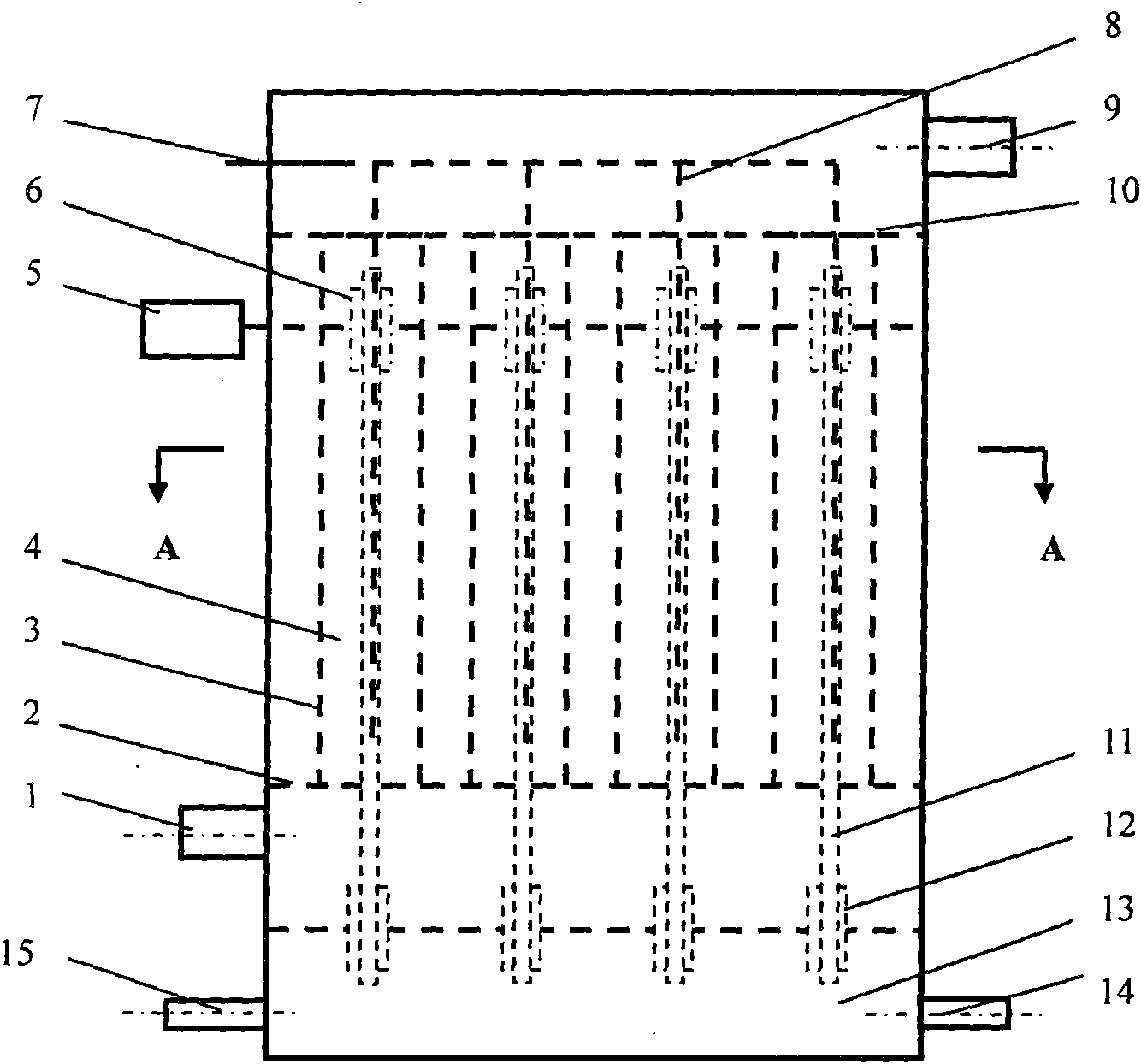

[0031] refer to figure 2 : A purification device for harmful exhaust gas, comprising a gas inlet 1, a lower baffle plate 2, a cylindrical electrode plate 3, a gas circulation space 4, a conveyor belt drive motor 5, an upper conveyor pulley 6, a corona high-voltage connection 7, and a corona wire 8. Gas outlet 9, upper baffle 10, conveyor belt 11 with absorbent on the surface, lower conveyor pulley 12, absorbent slurry pool 13, absorbent slurry inlet 14, absorbent slurry outlet 15 at the bottom of the device.

[0032] The treatment process is to introduce the gas containing harmful gas to be treated into the reactor through the gas inlet 1, and the gas flow flows from bottom to top in the cylinder, and in the flow channel, under the action of corona discharge, the harmful gas in the gas flow is eliminated Oxidation, decomposition, and then in the gas-solid absorption reaction zone, the acidic product in the product reacts with the absorbent and is absorbed by the absorbent. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com