Epoxy silsesquioxane/epoxy resin hybridized glue for packaging photoelectric devices and preparation method thereof

A technology of silsesquioxane and epoxy resin, which is applied in the direction of epoxy resin glue, chemical instruments and methods, electrical components, etc., can solve the problem of difficulty in meeting the application requirements of optoelectronic device packaging, poor fatigue resistance and impact resistance, and adhesion Low strength and other problems, to achieve the effect of improving bond strength and elongation at break, good electrical properties, and small curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

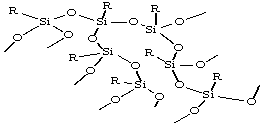

[0031] 1. Synthesis of epoxy silsesquioxane:

[0032] a) Add 10 mL of organic solvent tetrahydrofuran, 25 mL of organosiloxane γ-(2,3 glycidoxy)propyltrimethoxysilane and 5 mL of deionized water into the reaction device.

[0033] b) 11 mL of formic acid catalyst was slowly added dropwise, the temperature was raised to 65° C., and the reaction was stirred for 6 h.

[0034] c) After removing water under reduced pressure, 5 mL of tetrahydrofuran was added, and the system continued to react for 2 h.

[0035] d) removing water and solvent under reduced pressure to obtain epoxy silsesquioxane.

[0036] e) Add trimethylchlorosilane, the volume ratio of which to epoxysiloxane is 0.01:1.

[0037] 2. Preparation of epoxy silsesquioxane / epoxy resin hybrid adhesive for photoelectric packaging:

[0038] a) Weigh 1.0 g of the above-mentioned product and 1.0 g of bisphenol A epoxy resin, and mix them uniformly at 45°C.

[0039] b) Add 0.02 g of triethylamine and mix well.

[0040] c) Ad...

Embodiment 2

[0044] 1. Synthesis of epoxy silsesquioxane:

[0045] a) 15 mL of organic solvent tetrahydrofuran, 28 mL of organosiloxane γ-(2,3 glycidoxy)propyltrimethoxysilane and 7 mL of deionized water were added to the reaction device.

[0046] b) 13 mL of formic acid catalyst was slowly added dropwise, the temperature was raised to 65° C., and the reaction was stirred for 6 h.

[0047] c) After removing water under reduced pressure, 6 mL of organic solvent tetrahydrofuran was added, and the system continued to react for 2 h.

[0048] d) removing water and solvent under reduced pressure to obtain epoxy silsesquioxane.

[0049] e) Add trimethylchlorosilane, the volume ratio of which to epoxysiloxane is 0.01:1.

[0050] 2. Preparation of epoxy silsesquioxane / epoxy resin hybrid adhesive for photoelectric packaging:

[0051] a) Weigh 0.4g of the above-mentioned product and 0.6g of bisphenol A epoxy resin, and mix them uniformly at 45°C.

[0052] b) Add 0.015 g of triethylamine and mix w...

Embodiment 3

[0057] 1. Synthesis of epoxy silsesquioxane:

[0058]a) 22 mL of organic solvent tetrahydrofuran, 34.86 mL of organosiloxane γ-(2,3 glycidoxy)propyltrimethoxysilane and 11.31 mL of deionized water were added to the reaction device.

[0059] b) 14.5 mL of formic acid catalyst was slowly added dropwise, the temperature was raised to 80°C, and the reaction was stirred for 6 h.

[0060] c) After removing water under reduced pressure, 8 mL of organic solvent tetrahydrofuran was added, and the system continued to react for 6 h.

[0061] d) removing water and solvent under reduced pressure to obtain epoxy silsesquioxane.

[0062] e) Add trimethylchlorosilane, the volume ratio of which to epoxysiloxane is 0.01:1.

[0063] 2. Preparation of epoxy silsesquioxane / epoxy resin hybrid glue for optoelectronic device packaging:

[0064] a) Weigh 0.3g of the above-mentioned product and 0.7g of bisphenol A epoxy resin, and mix them uniformly at 45°C.

[0065] b) Add 0.02 g of triethylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com