Large two-stroke diesel engine with exhaust gas scrubber

A diesel engine, two-stroke technology, applied in the direction of machines/engines, engine components, combustion engines, etc., can solve the problems of fuel consumption, large energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

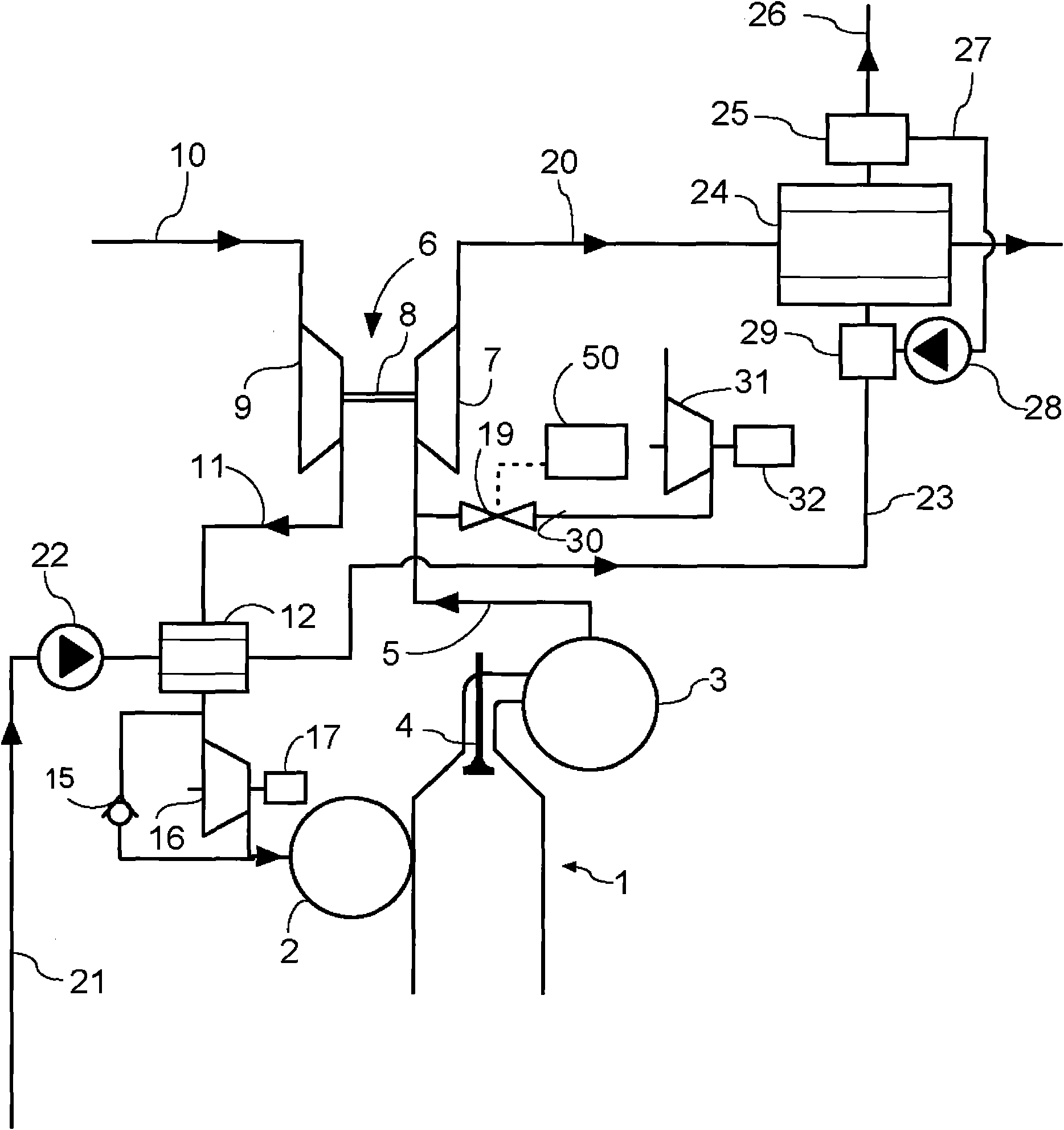

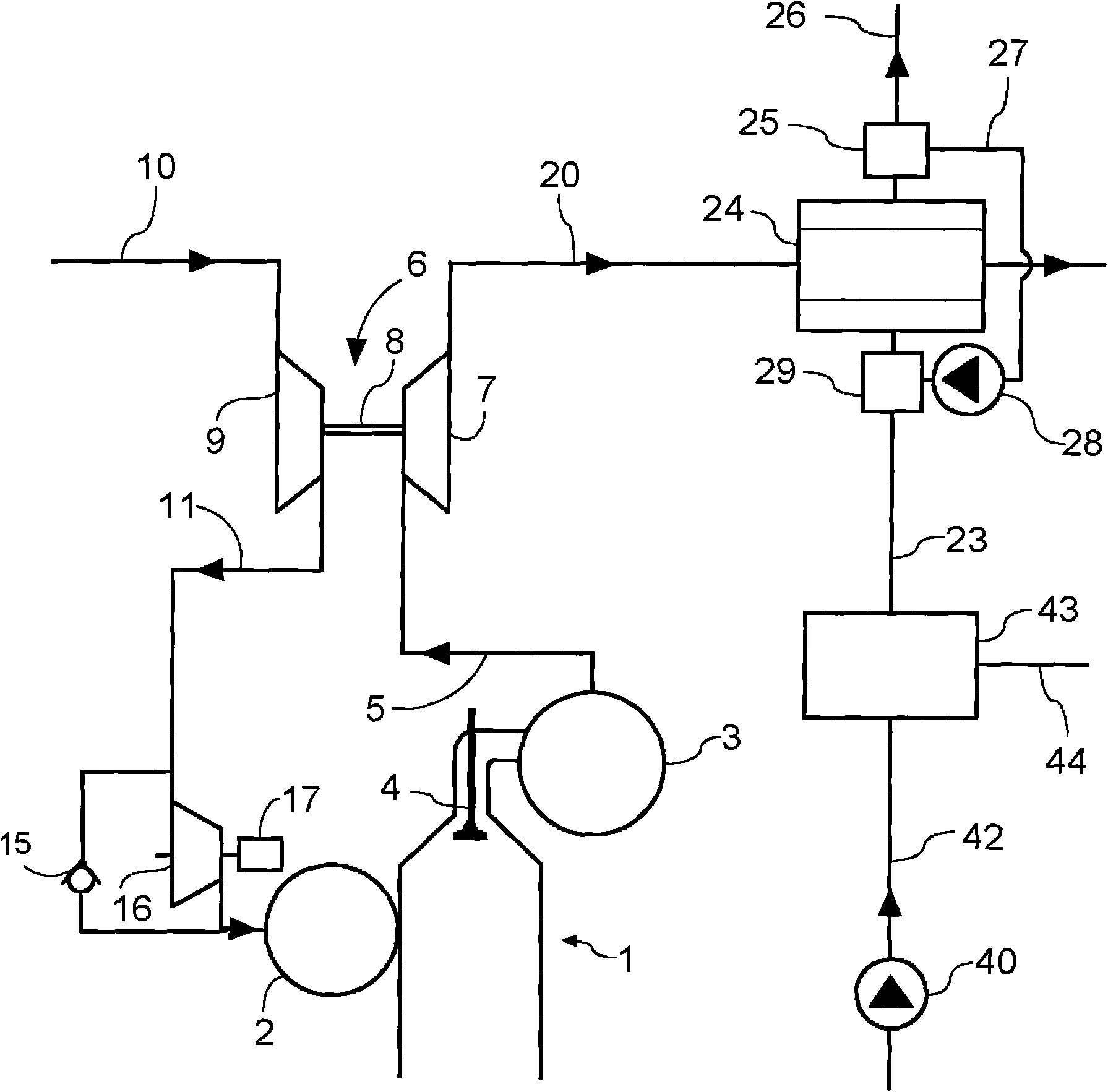

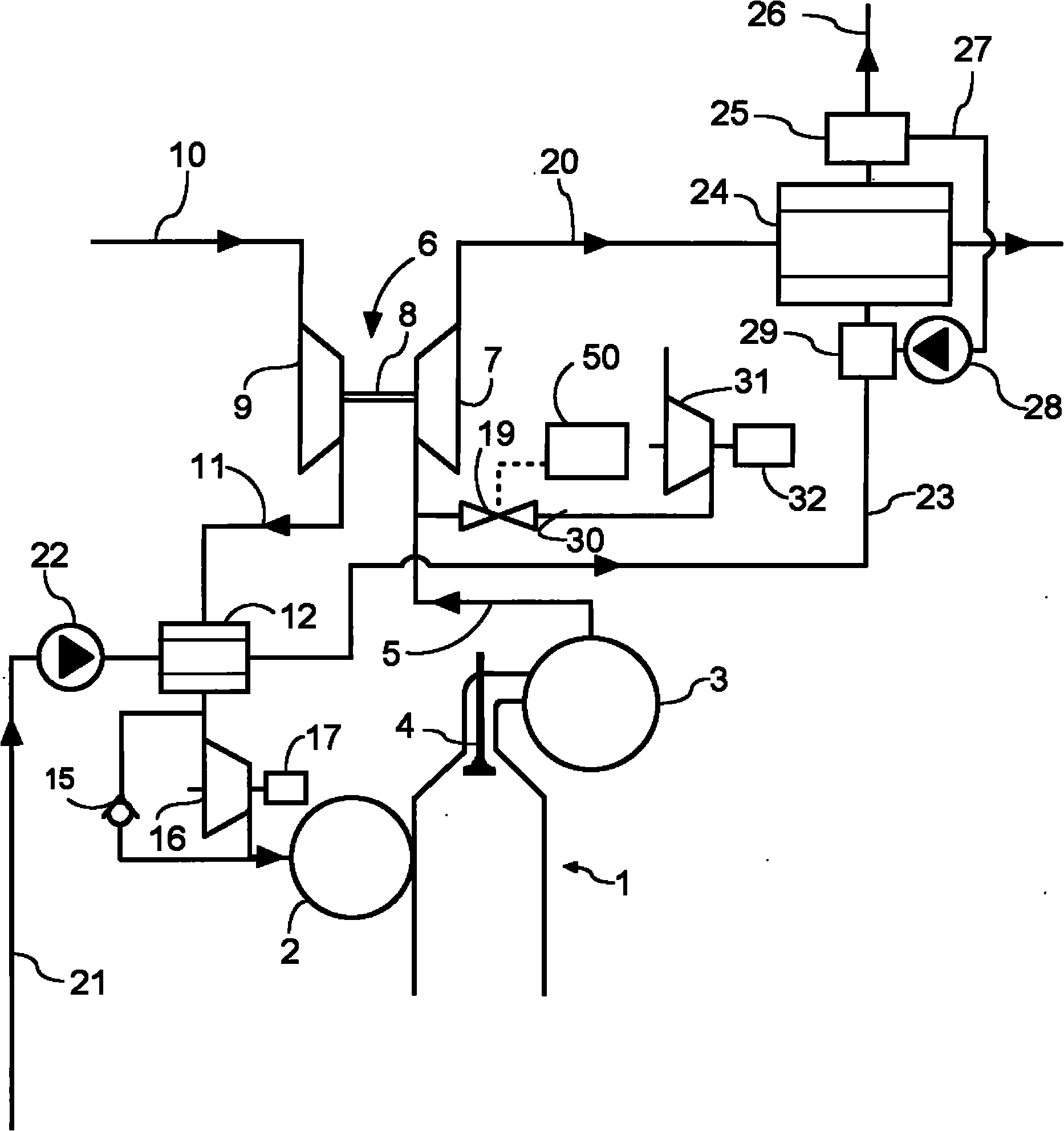

[0017] In the following detailed description, the invention will be described by way of preferred embodiments. figure 1 A diagram representing a crosshead large turbocharged two-stroke diesel engine 1 with an intake and exhaust system is shown. The engine 1 has a charge air receiver 2 and an exhaust gas receiver 3 . The exhaust valve belonging to the combustion chamber is indicated by 4 . For example, the engine 1 may be used as a main engine in a marine vessel or as a stationary engine for operating a generator in a power station. The total output of the engine may for example be in the range of 5,000 to 110,000 kw. The engine 1 is operated on heavy fuel oil and is therefore provided with a heavy fuel oil system comprising a heated heavy fuel oil tank and a heated heavy fuel oil piping system (not shown). Since heavy fuel oil is extremely viscous at ambient temperature, these heated elements of the fuel injection system are also heated during engine shutdown. Additionally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com