Method for improving gelling performance of minced Tilapia mossambica products

A technology for surimi products and tilapia, which is applied in food preparation, application, food science and other directions, can solve the problems of weakening the flavor of fish meat, reducing the whiteness of products, etc., so as to reduce the risk of food safety problems, improve the gel performance, and the coagulation. Excellent glue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

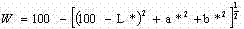

Image

Examples

example 1

[0037] Example 1 Production of fish and ham sausage

[0038] (1) Preparation of surimi: Tilapia and yellow croaker are used as raw materials. The raw materials are gutted and meat harvested by a meat harvester. The resulting fish paste is rinsed twice. The water ratio is 1:3 (w:w). After rinsing, dehydration and fine filtration, the moisture content of tilapia and croaker surimi are 76% (w:w) and 80% (w:w) respectively. ;

[0039] (2) Mixing of surimi: The mass ratio of tilapia surimi to croaker surimi is 4:6 (w:w), and the two kinds of surimi are evenly mixed to obtain mixed surimi;

[0040] (3) Chop and mix: add the mixed surimi to the chopping machine and mix for 5 minutes, then add 2% of the weight of the surimi, salt, 1% of the weight of the surimi, soybean protein isolate, and 5% of the weight of the surimi, and mix for 15 minutes . During the chopping process, 35% ice by weight of the surimi was added to keep the temperature of the surimi paste below 15°C;

[0041] ...

example 2

[0043] Example 2: Making fried fish balls

[0044] (1) Surimi preparation: yellow croaker and leftover meat from tilapia fillets are used as raw materials. Yellow croaker is viscerally removed and meat is harvested by meat harvester to make fish paste; the corner meat is directly harvested by meat harvester to make fish paste. Rinse the obtained surimi twice. During each rinsing, the temperature of the rinsing water is kept at 5°C, and the ratio of meat to water is 1:4 (w:w). The moisture content of fish surimi is 79% (w:w), 76% (w:w);

[0045] (2) Mixing of surimi: mix the two kinds of surimi according to the mass ratio of tilapia surimi to croaker surimi 4:2 (w:w) to prepare mixed surimi;

[0046] (3) Chop and mix: add the mixed surimi to the chopping machine and mix for 6 minutes, then add 2.5% salt by weight of surimi, soybean protein isolate by 1% by weight of surimi, and starch by 5% by weight of surimi, and mix for 13 minutes . During the chopping process, 45% ice b...

example 3

[0050] Example 3 Kamaboko making

[0051] (1) Preparation of surimi: Tilapia and yellow croaker are used as raw materials. The raw materials are gutted and meat harvested by a meat harvester. The resulting surimi is rinsed twice. The water ratio is 1:5 (w:w). After rinsing, it is dehydrated and finely filtered. The moisture content of tilapia and croaker surimi are 79% (w:w) and 79% (w:w) respectively. ;

[0052] (2) Mixing of surimi: mix the two kinds of surimi according to the mass ratio of tilapia surimi to croaker surimi 4:3 (w:w) to prepare mixed surimi;

[0053] (3) Chop and mix: Add the mixed surimi into the chopping machine and mix for 5 minutes, then add 2.5% salt by weight of surimi, soybean protein isolate by 1% by weight of surimi, and starch by 5% by weight of surimi, and mix for 13 minutes . During the chopping process, 38% ice by weight of the surimi was added to keep the temperature of the surimi pulp below 15°C;

[0054] (4) Forming and shaping: fill the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com