Encapsulation method of MEMS infrared sensor with infrared focusing function

An infrared sensor and packaging method technology, which is applied to instruments, decorative arts, measuring devices, etc., can solve the problems of infrared heat loss, reduce the sensitivity of infrared detectors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

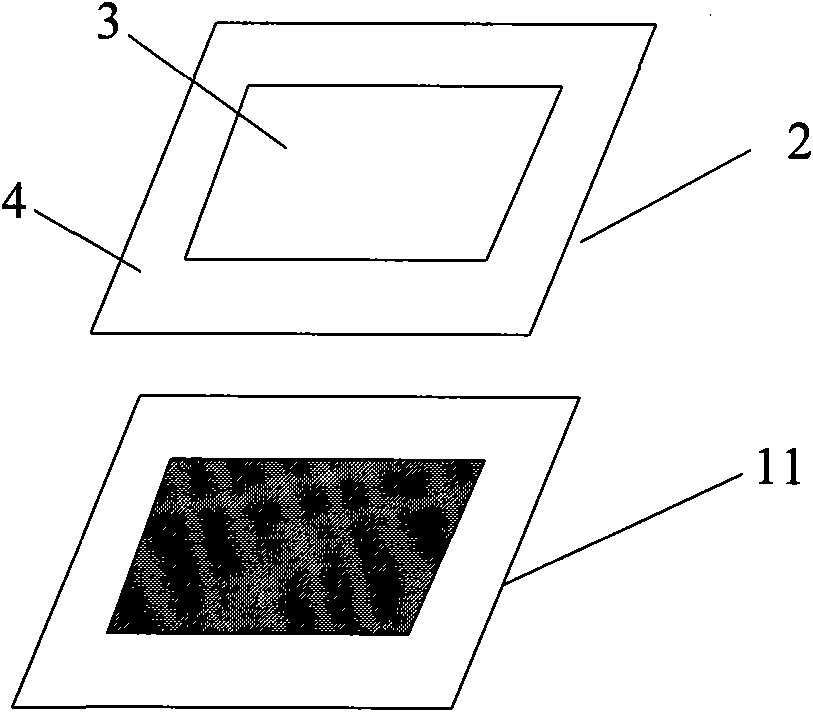

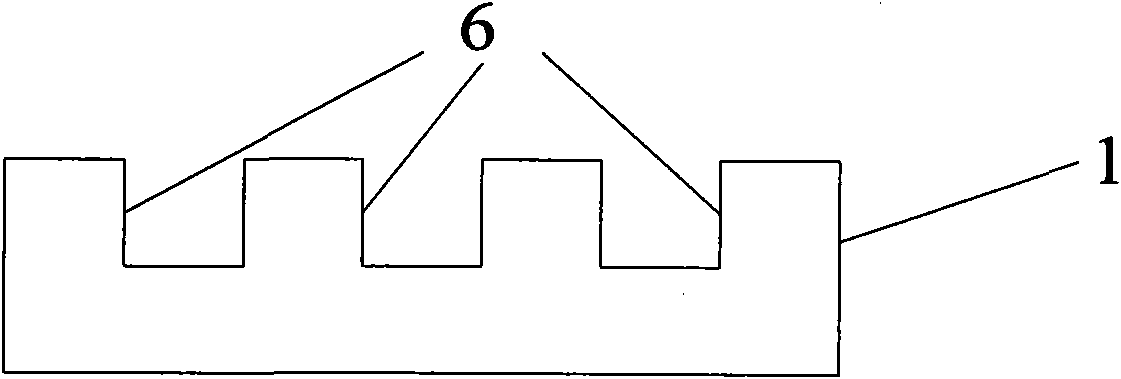

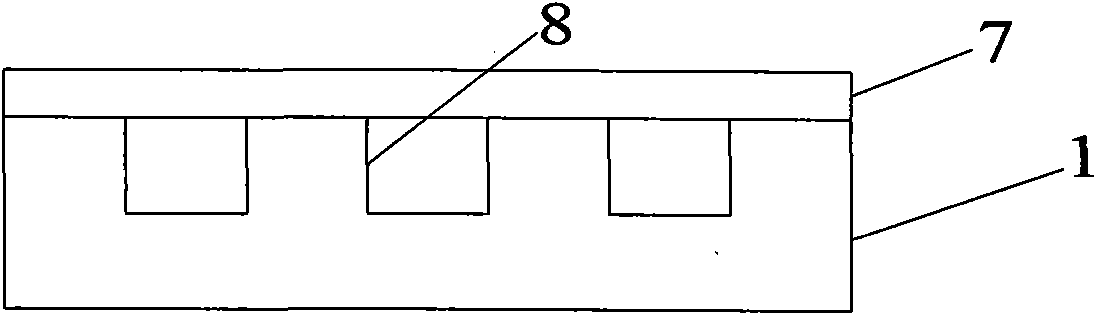

[0033] Embodiment 1 A kind of packaging method of MEMS infrared sensor with infrared focusing function, comprises the following steps: the first step, according to MEMS infrared sensor (can select infrared thermopile for use, it utilizes the variation of the thermocouple measurement temperature of multiple groups connected in series, One end of the thermocouple is connected to the infrared absorption area. Since the temperature rises after absorbing infrared rays, the thermocouple generates a temperature difference. According to the Seebeck effect, the thermopile outputs a voltage. The higher the temperature, the more infrared rays are absorbed, the greater the output voltage value, and the realization In order to detect infrared rays, n-type polysilicon / aluminum thermocouples are used here. For example, the chip size is 1*1 mm), and the pattern and size of the package cavity are determined, including the side length of the cavity and the size of the package area. width, design...

Embodiment 2

[0041] Embodiment 2 A wafer-level packaging method for a MEMS infrared sensor, comprising the following steps:

[0042] The first step is to determine the size of the packaging cavity and the packaging frame according to the structure of the MEMS infrared sensor chip, and design the layout size of the packaging glass microcavity. The MEMS infrared sensor uses multiple sets of thermocouples connected in series to measure the temperature. According to the Seebeck effect, when there is a temperature difference between the two ends of the thermocouple, a voltage will be generated, and the greater the temperature difference between the hot and cold ends, the greater the output voltage. Multiple sets of thermocouples connected in series can improve the detection sensitivity of the thermopile. The hot end of the thermopile is in contact with the infrared absorption area, and the cold end is away from the infrared absorption area, and is insulated with a heat-insulating material, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com