Mn-Zn soft magnetic ferrite for saving energy and lighting, and preparation method of obtained magnetic core

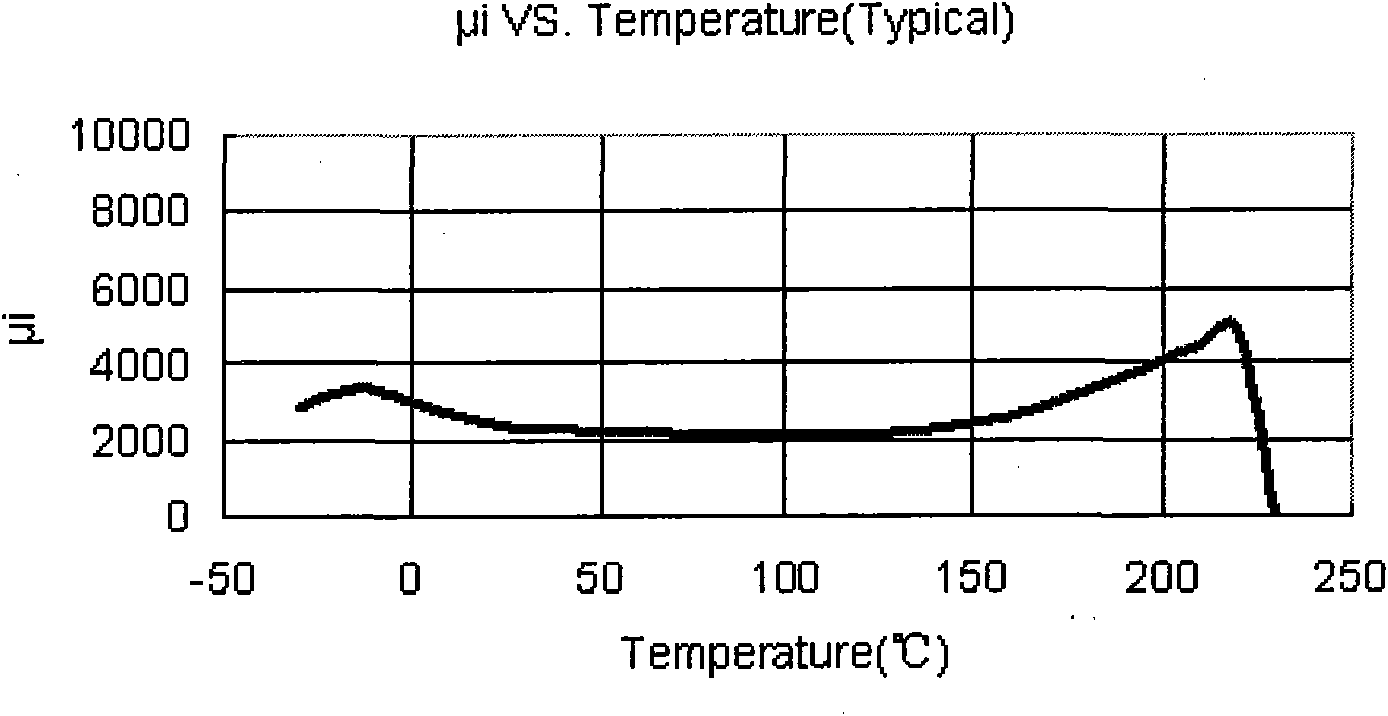

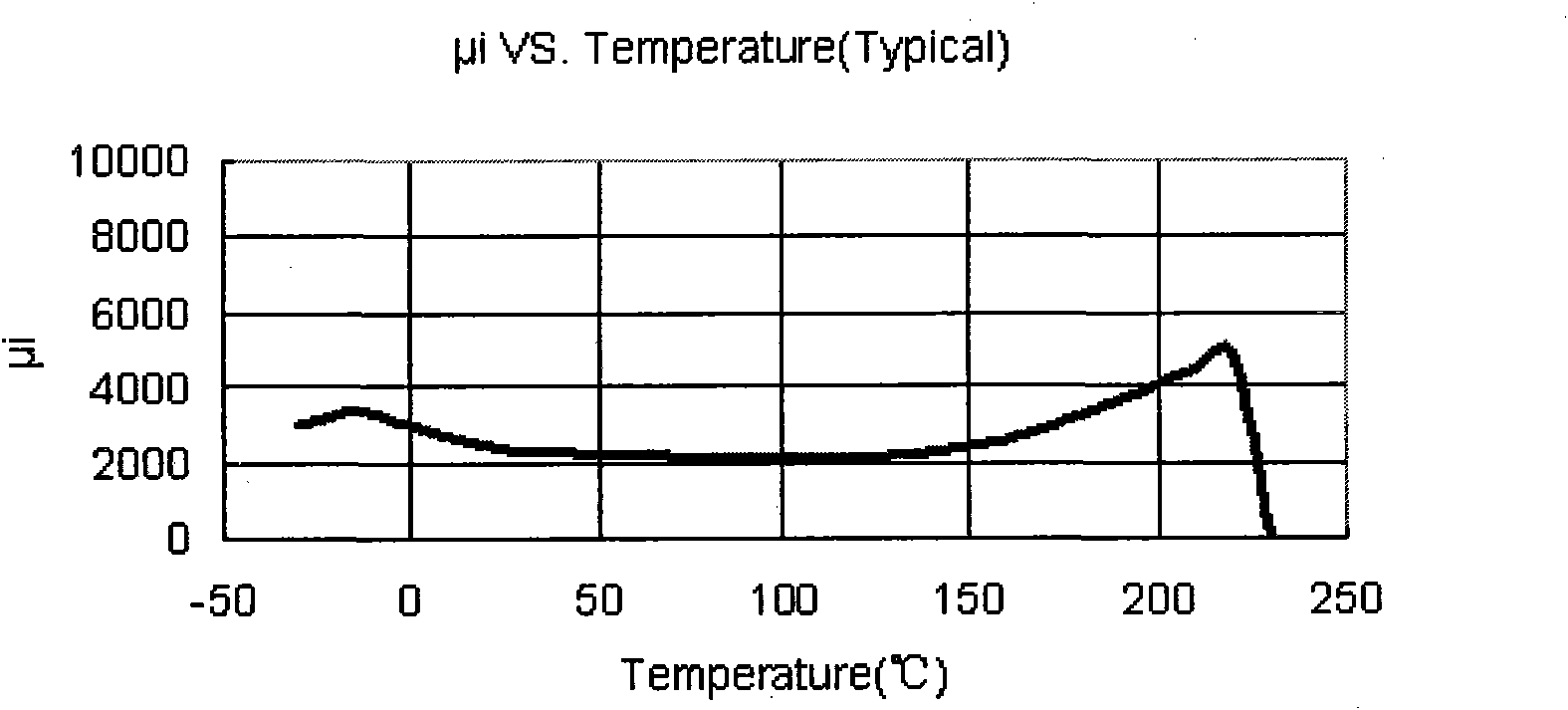

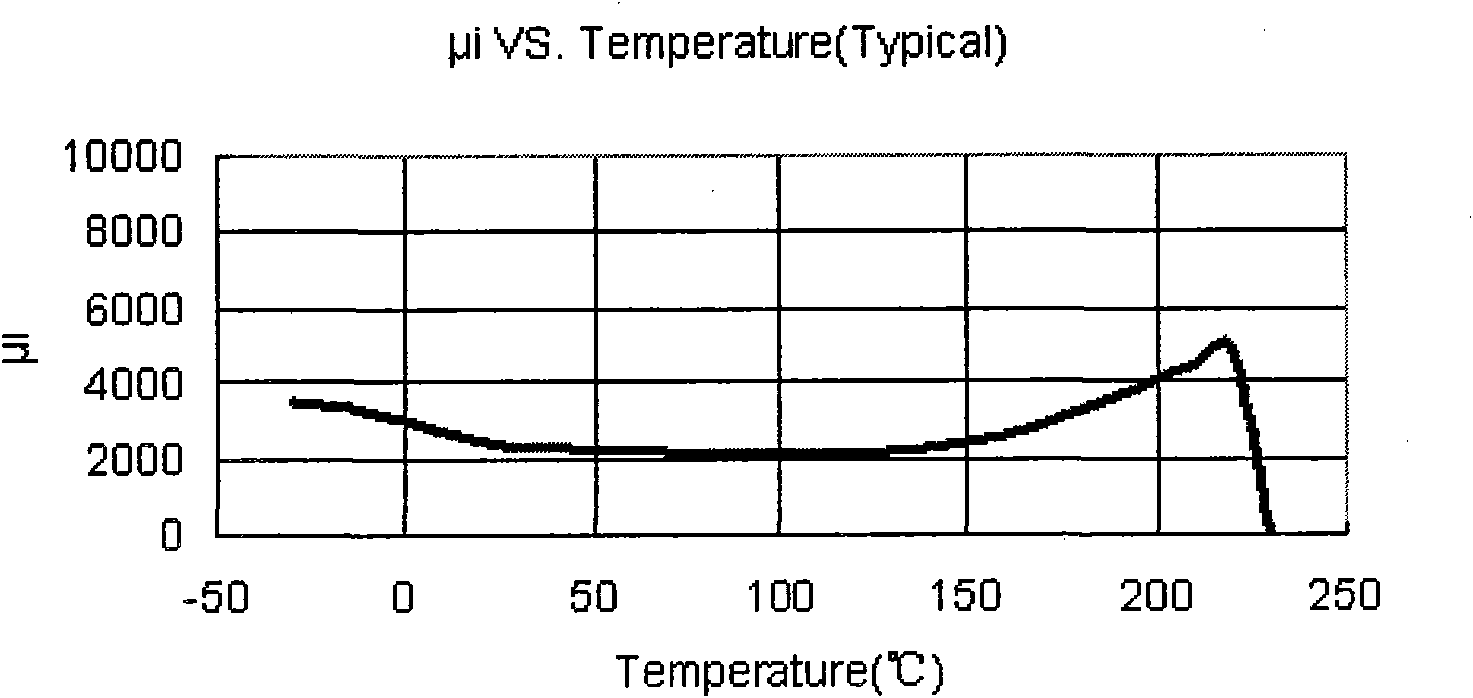

A manganese-zinc soft magnet and soft ferrite technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of no μi temperature curve, large difference in μi, and failure to meet the high-quality requirements of energy-saving lighting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Press Fe 2 o 3 : MnO: ZnO = 52.2: 37.5: 10.3 for a batching, where Fe 2 o 3 German ThyssenKrupp iron red, purity ≥ 99.3wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , purity ≥ 98.8wt%, ZnO adopts ZnO from Haimen, Zhejiang, indirect method, purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 2 to 6 hours. Spray drying and pre-calcination are carried out. The pre-calcination temperature is 800-960° C. and the pre-calcination time is 30-90 minutes to obtain a calcined material. Pre-fired materials are used for secondary batching, put into a ball mill for secondary ball milling, and A and B auxiliary materials are added. The A group auxiliary materials are CaCO with a weight percentage of 50-500ppm 3 , SiO 2 One or two of them, the composition of the auxiliary materials in group B is Bi with a weight percentage of 100-2000ppm 2 o 3 ...

Embodiment 2

[0015] Press Fe 2 o 3 : MnO: ZnO = 53.2: 38: 10.3mol formula for a batching, where Fe 2 o 3 German ThyssenKrupp iron red, purity ≥ 99.3wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , purity ≥ 98.8wt%, ZnO adopts the ZnO indirect method in Haimen, Zhejiang, with a purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 2 to 6 hours. Spray drying and pre-calcination are carried out. The pre-calcination temperature is 800-960° C. and the pre-calcination time is 30-90 minutes to obtain a calcined material. Pre-fired materials are used for secondary batching, put into a ball mill for secondary ball milling, and A and B auxiliary materials are added. The A group auxiliary materials are CaCO with a weight percentage of 50-500ppm 3 , SiO 2 One or two of them, the composition of the auxiliary materials in group B is Bi with a weight percentage of 100...

Embodiment 3

[0017] Press Fe 2 o 3 : MnO: ZnO = 54.2: 37.5: 10.3mol% of the formula for a batching, where Fe 2 o 3 German ThyssenKrupp iron red, purity ≥ 99.3wt%, MnO converted to Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 , purity ≥ 98.8wt%, ZnO adopts ZnO from Haimen, Zhejiang, indirect method, purity ≥ 99.7wt%. Pour the three raw materials into a mixing tank, add a dispersant and deionized water, fully stir and mix, and perform a ball mill for 2 to 6 hours. Spray drying and calcining are carried out, the calcining temperature is 800-960° C., the calcining time is 30-90 minutes, and the calcined material is obtained. The calcined material is used for secondary batching, put into a ball mill for secondary ball milling, and auxiliary materials A, B, and C are added. The auxiliary material of group A is CaCO with a weight percentage of 50-500ppm 3 , SiO 2 One or two of them, the composition of the auxiliary materials in group B is Bi with a weight percentage of 100-200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com