Composite sensing material of fluorescent conjugated polymer and organic metal complex and application

A conjugated polymer and fluorescent polymer technology, which is applied in the fields of luminescent materials, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of no fluorescence, weak fluorescence, and difficult film formation, and achieves easy high integration and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

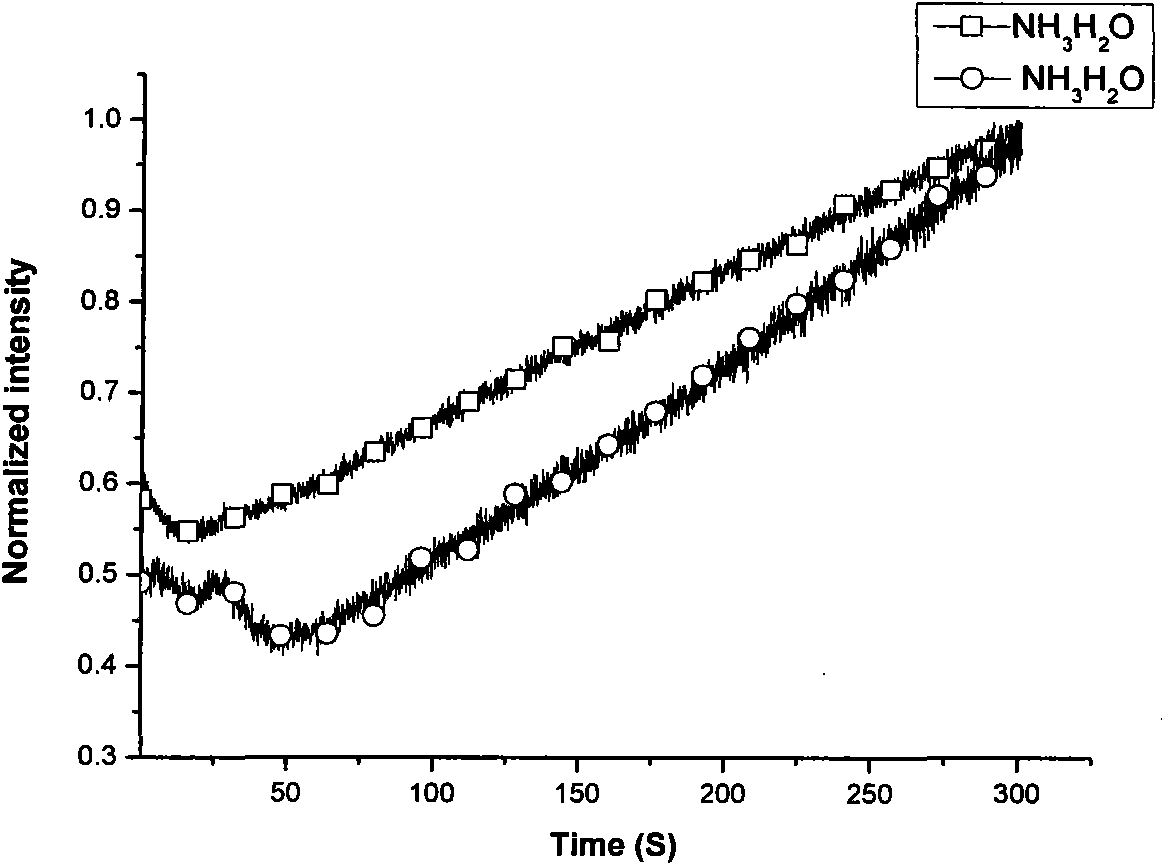

[0037] Embodiment 2 (ammonia sensing), the process is as follows:

[0038] Place a small ball of cotton at the bottom of the quartz pool, drop a few drops of ammonia water on the cotton, put a small ball of cotton on it, and place the composite sensing film prepared in Example 1 on the cotton to test its time response curve. It can be seen that the fluorescence of the composite sensing film decreased slightly in the first 50 seconds, and then the fluorescence gradually increased, and the fluorescence intensity increased by 40% within 300 seconds. The results are shown in figure 1 .

Embodiment 3

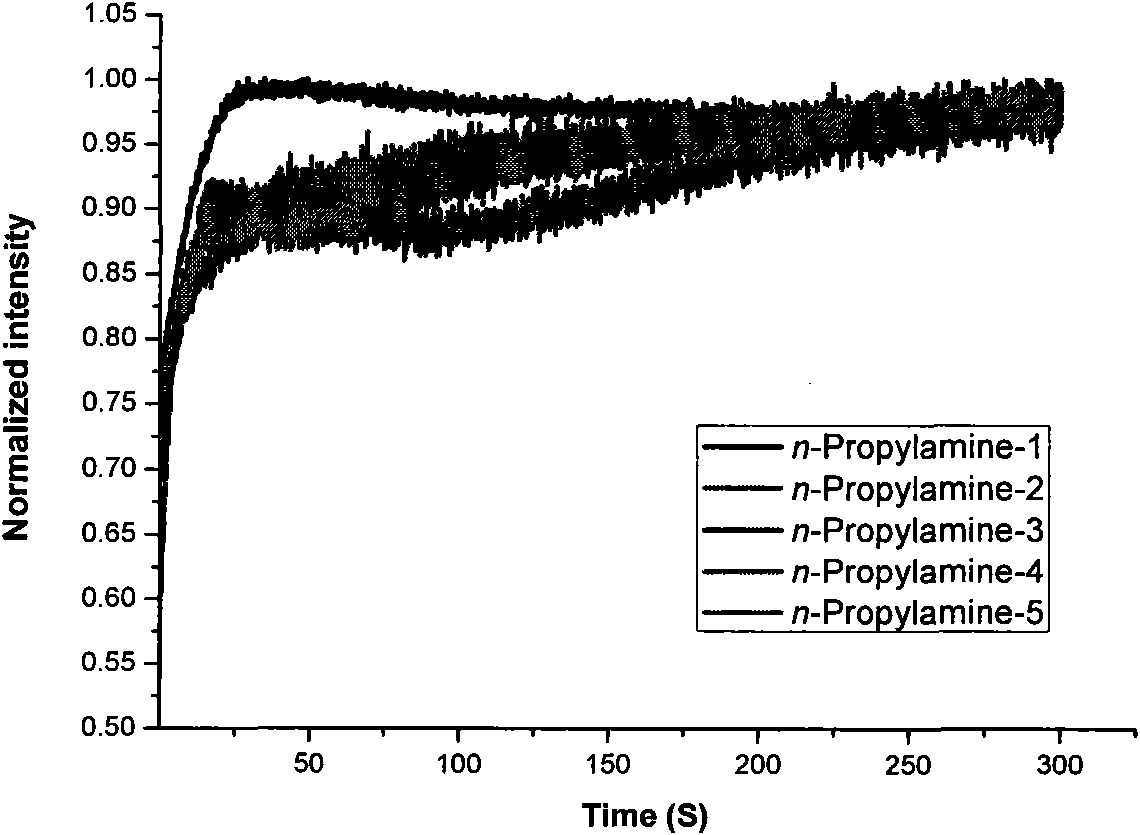

[0039] Embodiment 3 (n-propylamine sensing)

[0040] Place a small ball of cotton at the bottom of the quartz pool, drop a few drops of n-propylamine on the cotton, put a small ball of cotton on it, and place the composite sensing film provided by the invention on the cotton to test its time response curve. It can be seen that the fluorescence of the composite sensing film reaches saturation in the first 30 seconds and does not increase thereafter. Fluorescence intensity increases by 25-35% within 30 seconds, see results figure 2 .

Embodiment 4

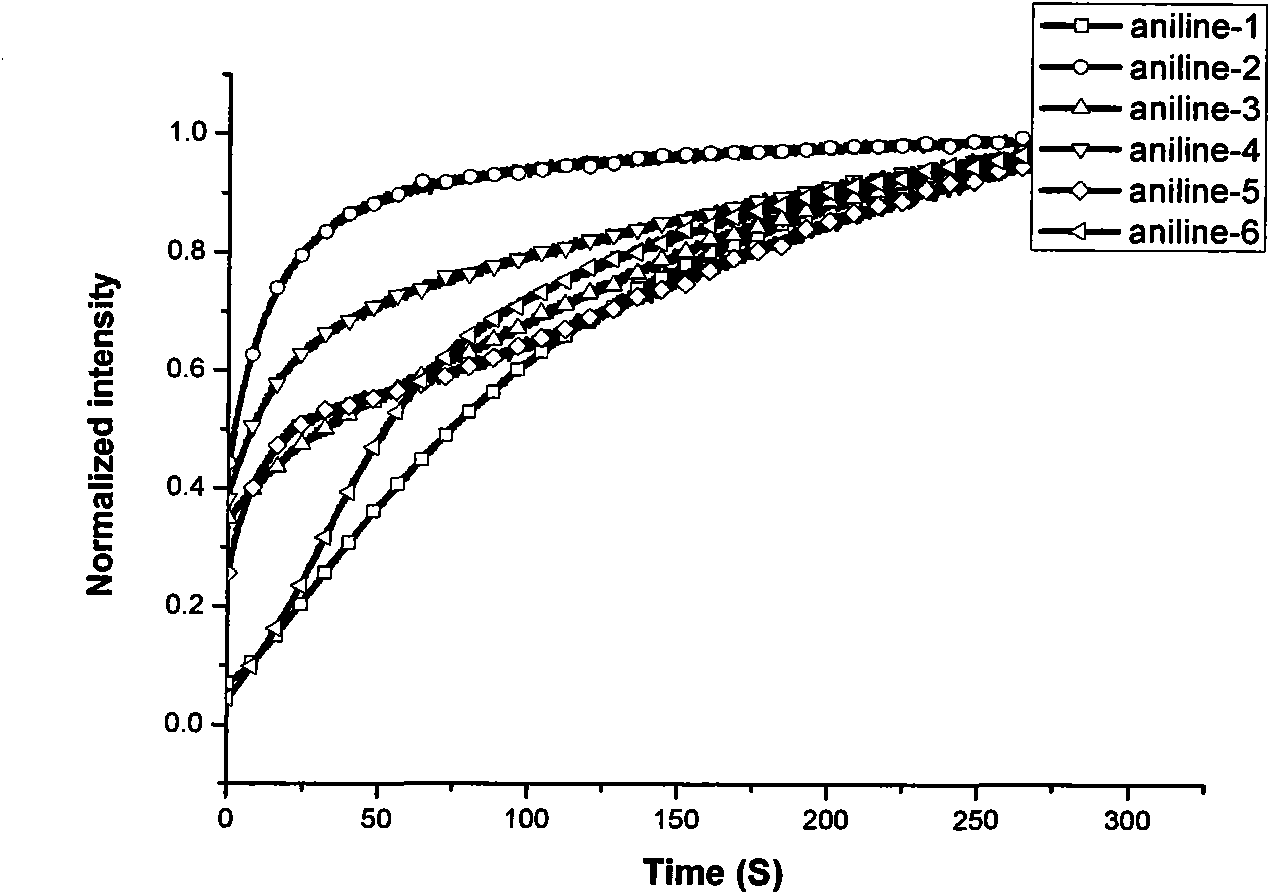

[0041] Embodiment 4 (aniline sensing)

[0042] Place a small ball of cotton at the bottom of the quartz pool, drop a few drops of aniline on the cotton, put a small ball of cotton on it, and place the composite sensing film on the cotton to test its time response curve. It can be seen that the fluorescence of the composite sensing film reaches saturation in the first 100 seconds and does not increase thereafter. Fluorescence intensity increases by 50-90% within 25-100 seconds, see results image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com