Polyester-aramid guide bearing, thrust disc friction plate and manufacturing method thereof

A manufacturing method and thrust disc technology, which are applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of polluted environment, poor wear resistance, complicated procedures, etc., and achieve good acid and alkali resistance, long service life, improved The effect of abrasion resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

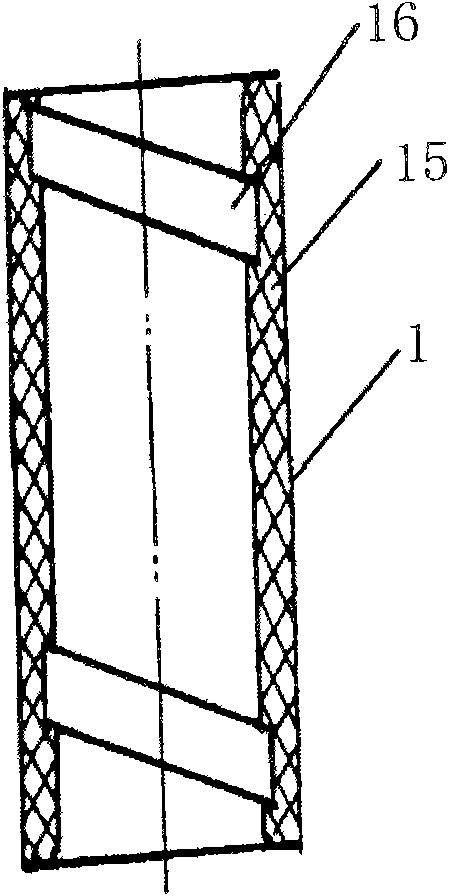

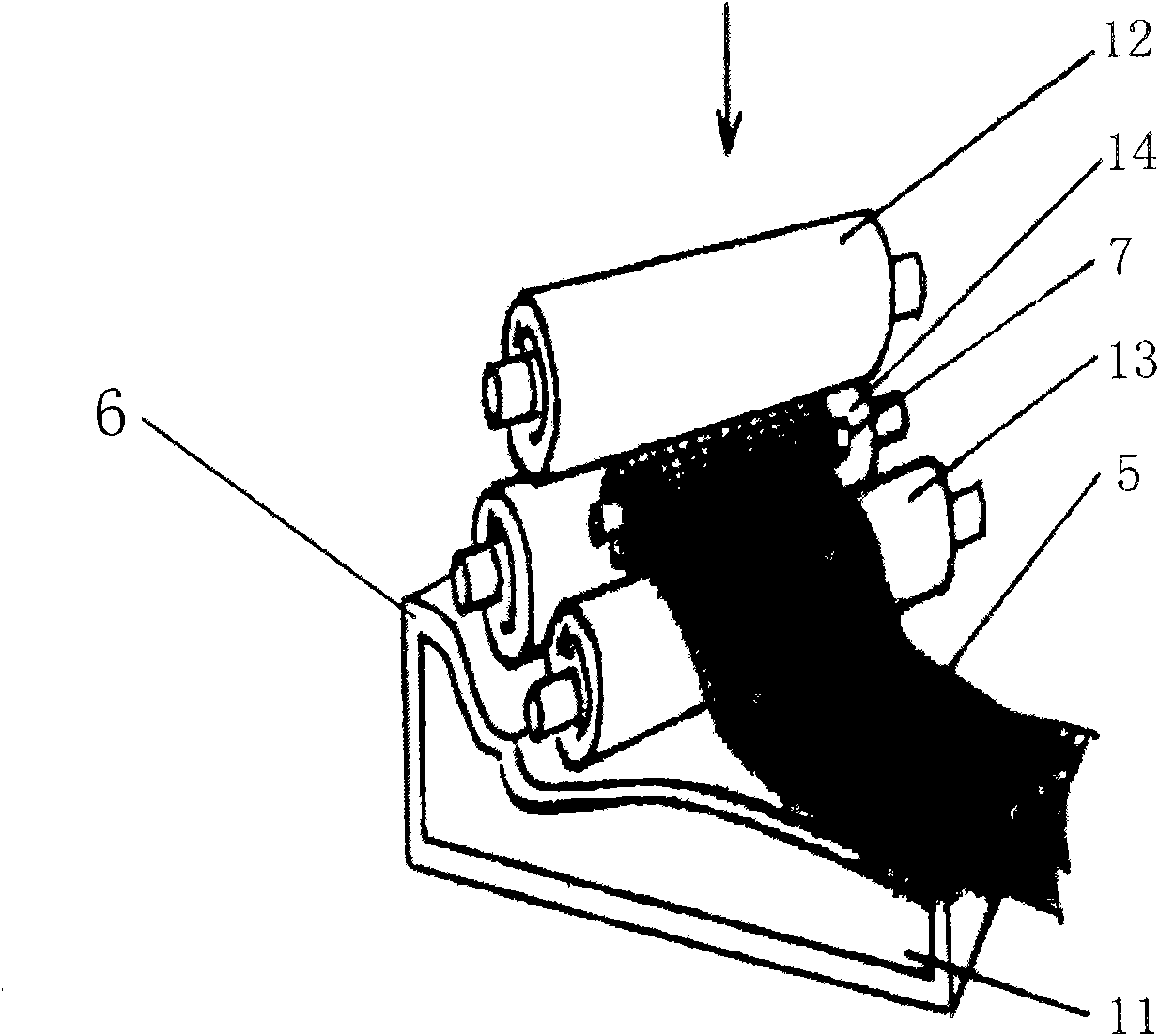

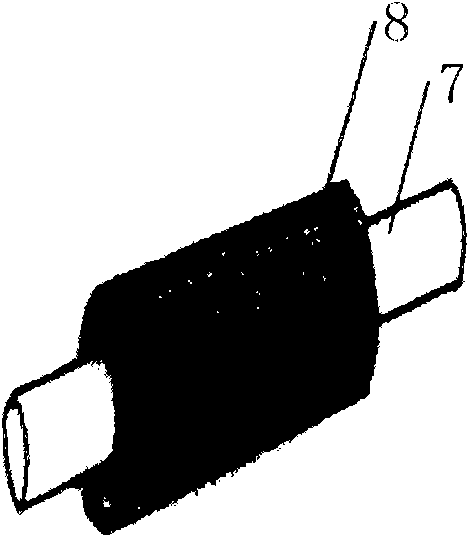

[0040] A polyester or aramid guide bearing and a thrust plate friction plate, characterized in that: the guide bearing 1 and the thrust plate friction plate 3 made of polyester or aramid form a pair of friction pairs; the outside of the guide bearing 1 is a pipe wall 15. There is also a water flow groove 16 in the pipe wall 15; the thrust plate friction plate 3 and the cast iron base 4 constitute the thrust plate 2, and the thrust plate friction plate 3 is arranged on the cast iron base 4; the thickness of the guide bearing 1 is 0.5mm, and the warp and weft density is 48 pieces / 10cm; the thickness of the thrust plate friction plate 3 is 0.5mm.

[0041] A method for manufacturing polyester, aramid guide bearings and thrust disc friction plates as described above, characterized in that:

[0042] The method consists of the following steps:

[0043] (1) Manufacture of the guide bearing: impregnate polyester or aramid cloth with polyvinyl butyral modified phenolic resin for 2 hour...

Embodiment 2

[0050] A polyester or aramid guide bearing and a thrust plate friction plate, characterized in that: the guide bearing 1 and the thrust plate friction plate 3 made of polyester or aramid form a pair of friction pairs; the outside of the guide bearing 1 is a pipe wall 15. There is also a water flow groove 16 in the pipe wall 15; the thrust plate friction plate 3 and the cast iron base 4 constitute the thrust plate 2, and the thrust plate friction plate 3 is arranged on the cast iron base 4; the thickness of the guide bearing 1 is 0.8mm, and the warp and weft density is 90 pieces / 10cm; the thickness of the friction plate 3 of the thrust plate is 0.8mm.

[0051] A method for manufacturing polyester, aramid guide bearings and thrust disc friction plates as described above, characterized in that:

[0052] The method consists of the following steps:

[0053] (1) Manufacture of the guide bearing: impregnate polyester or aramid cloth with polyvinyl butyral modified phenolic resin for...

Embodiment 3

[0060] A polyester or aramid guide bearing and a thrust plate friction plate, characterized in that: the guide bearing 1 and the thrust plate friction plate 3 made of polyester or aramid form a pair of friction pairs; the outside of the guide bearing 1 is a pipe wall 15. There is also a water flow groove 16 in the pipe wall 15; the thrust plate friction plate 3 and the cast iron base 4 constitute the thrust plate 2, and the thrust plate friction plate 3 is arranged on the cast iron base 4; the thickness of the guide bearing 1 is 0.6mm, and the warp and weft density is 60 pieces / 10cm; the thickness of the friction plate 3 of the thrust plate is 0.6mm.

[0061] A method for manufacturing polyester, aramid guide bearings and thrust disc friction plates as described above, characterized in that:

[0062] The method consists of the following steps:

[0063] (1) Manufacture of the guide bearing: impregnate polyester or aramid cloth with polyvinyl butyral modified phenolic resin for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com