Noncontact-type EGR (Exhaust Gas Recirculation) valve position sensor

An exhaust gas recirculation valve, non-contact technology, applied in the field of sensors, can solve problems such as damage, sensor failure, frequent sliding of contacts, etc., and achieve the effects of prolonging working life, accurate and more stable output signals, and good linear output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

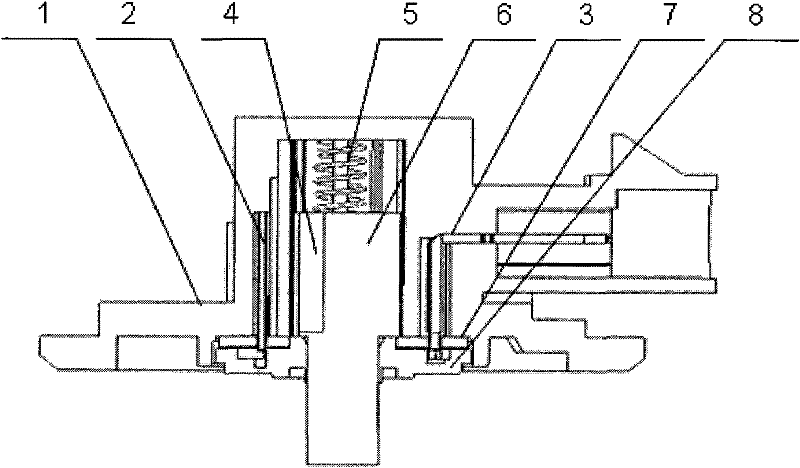

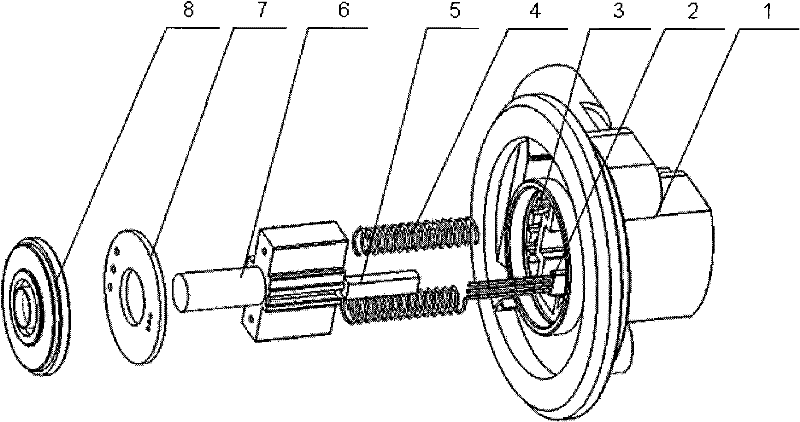

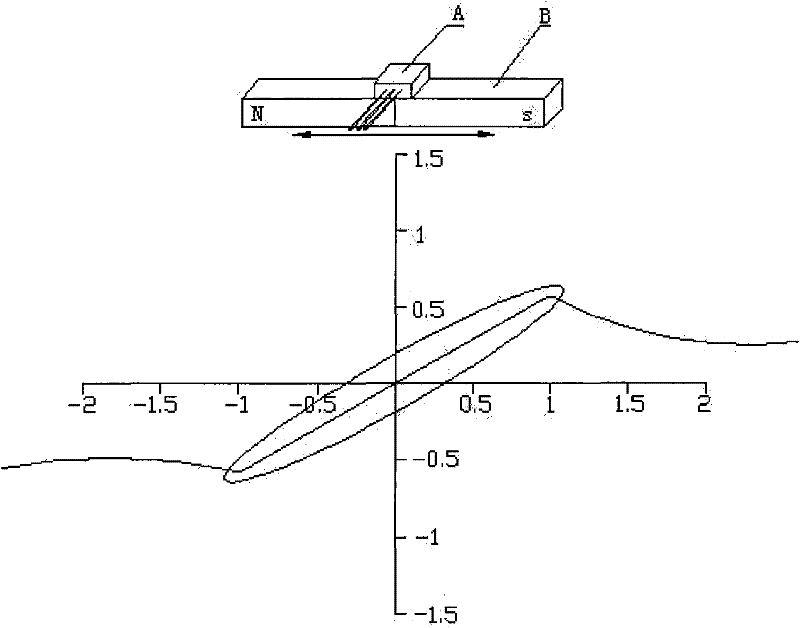

[0019] see figure 1 and figure 2 , The non-contact EGR valve position sensor includes a housing 1 , a circuit board 7 , a guide post 6 , a magnet block 5 , a Hall chip 2 , a terminal pin 3 and a rear cover 8 . The housing 1 is in the shape of a straw hat, and a guide post 6 is installed in the blind hole in the middle of the housing. The upper part of the guide post 6 is a square prism, and the lower part is a cylinder. . Two pull-back springs 4 are installed between the top surface of the quadrangular prism on the upper part of the guide post 6 and the bottom of the blind hole of the housing 1, and the magnet block 5 is embedded on one side of the quadrangular prism on the upper part of the guide post 6, corresponding to the Hall chip The surface of the magnet block 5 is an arc surface, which ensures that when the magnet block 5 moves, the sensing surface of the Hall chip 2 can obtain a linearly changing magnetic field; the length of the magnet block 5 is 12mm, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com