Formation method of zero object

A technology of zero mark and graphics, applied in the field of zero mark formation, can solve the problems of cumbersome forming process, etc., and achieve the effect of accelerating oxidation rate, saving cycle and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for forming the zero mark of the present invention is used in an epitaxial process including a buried layer pattern, comprising the following steps:

[0015] 1) The surface of the substrate is oxidized to form a pad oxide layer;

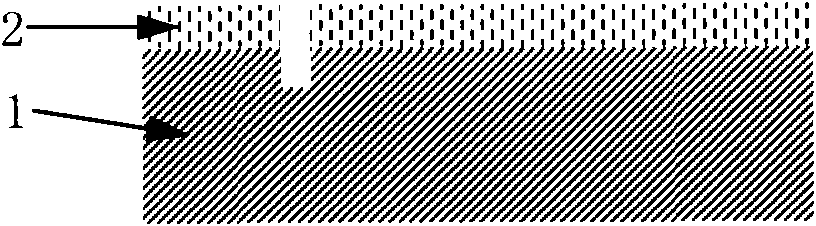

[0016] 2) Define the positions of the buried layer pattern and the zero mark pattern on the substrate 1 (generally silicon) with a photolithography mask that includes both the buried layer pattern and the zero mark pattern and the photolithography process;

[0017] 3) using the photoresist 2 formed in the photolithography process as a mask to perform buried layer ion implantation to form ion implantation regions at the buried layer pattern position 3 and the zero mark pattern position respectively;

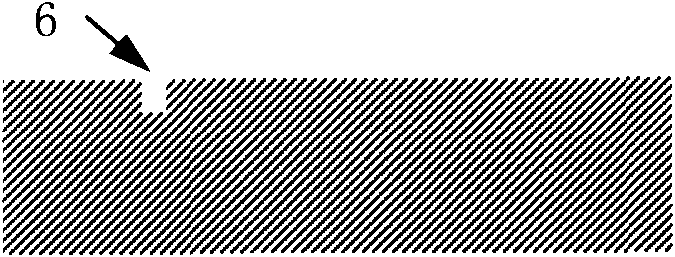

[0018] 4) Common process to remove photoresist and pad oxide layer (see Figure 2a and Figure 2b );

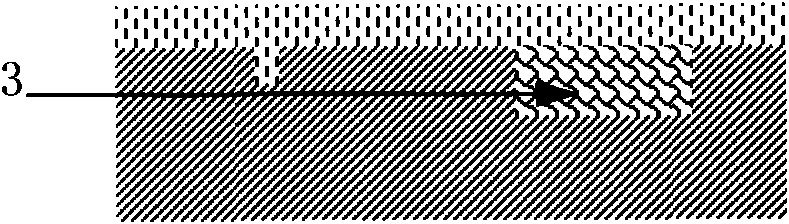

[0019] 5) Afterwards, heat treatment is carried out in an oxygen-containing atmosphere to oxidize the surface of the substrate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com