High-conductivity double perovskite aluminum-doped Sr2AlxMg1-xMoO6-Delta anode material and preparation method thereof

A sr2alxmg1-xmoo6-, double perovskite technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting battery output power, polarization, large gaps, etc., to achieve good chemical stability, improve conductivity The effect of improving the conductivity and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

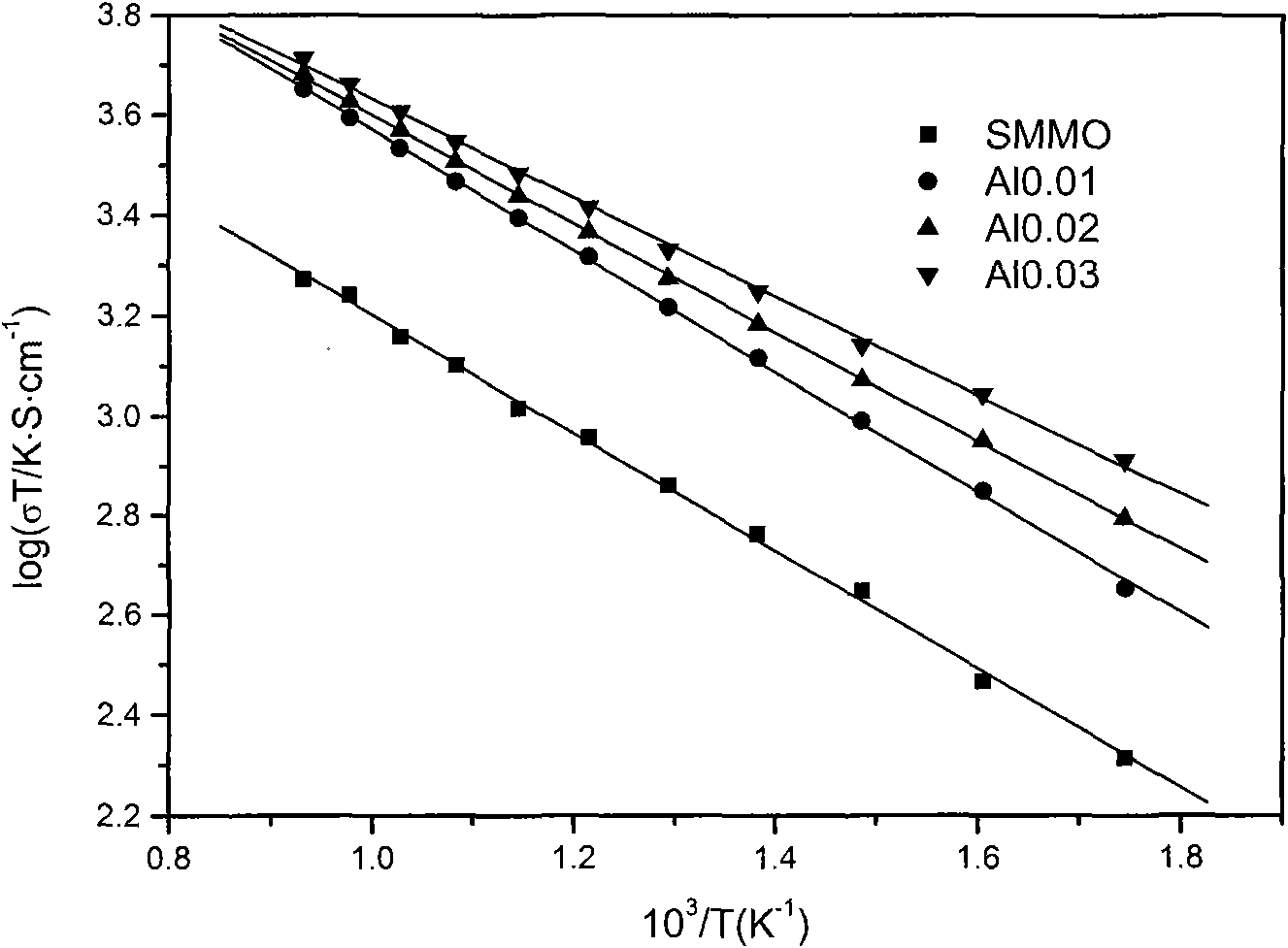

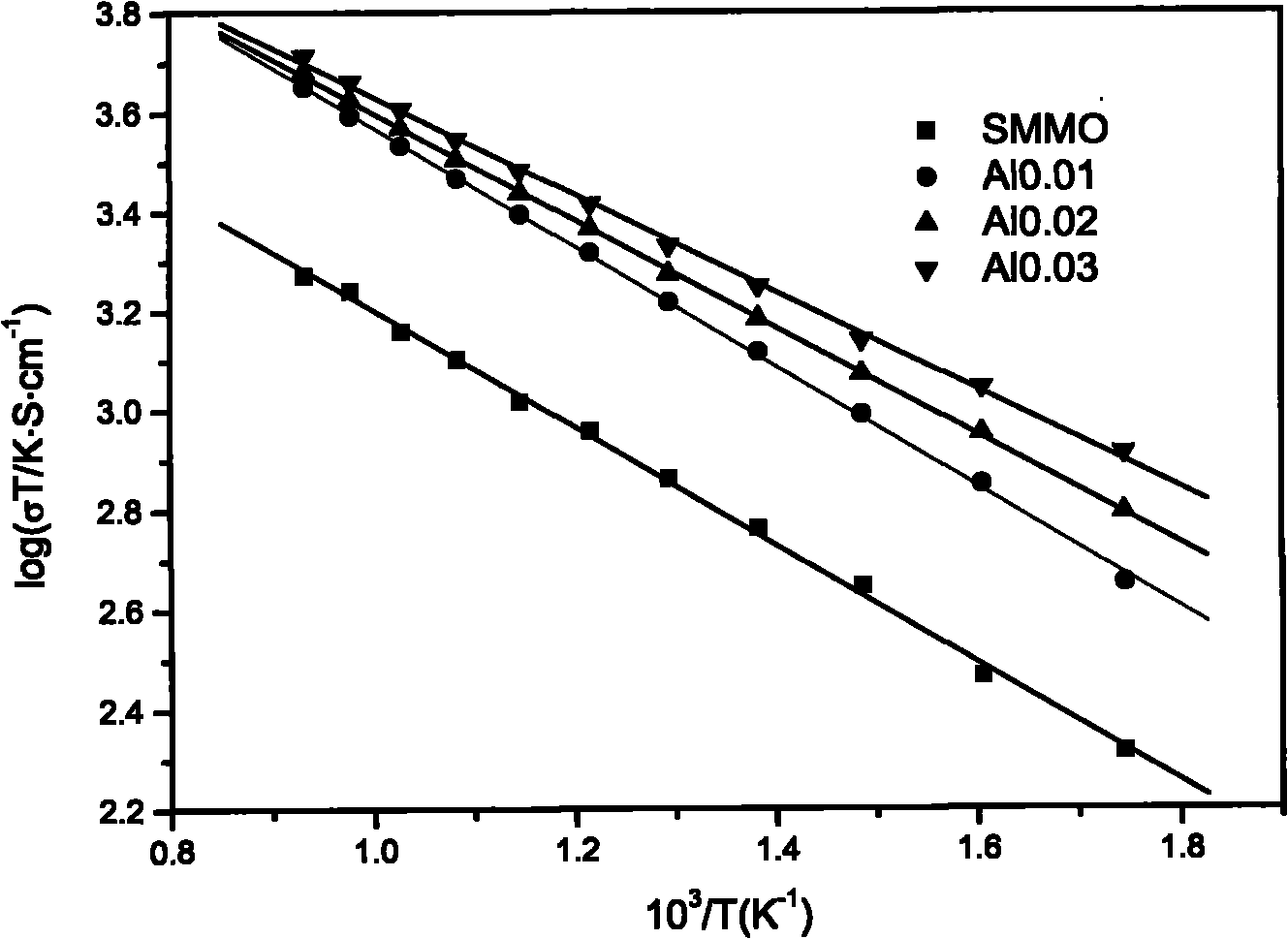

[0026] Synthesis of Sr by Citric Acid-Combustion Synthesis 2 Al x Mg 1-x MoO 6-δ (x=0.01) Dense sample. According to Sr 2 Al x Mg 1-x MoO 6-δ (x=0.01) stoichiometric ratio preparation, Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 Dissolve O in deionized water respectively, then add citric acid at a ratio of 1:2 between metal ions and citric acid, and keep stirring to make it evenly mixed. Heat and stir on the muffle furnace until combustion to form Sr 2 Al x Mg 1-x MoO 6-δ (x=0.01) Precursor powder. Grind the powder, put it into an electric furnace for roasting, the temperature is 800°C, and the holding time is 10h, so that the organic matter in it can be fully decomposed. Grind the calcined powder again, sieve, add (binder) polyvinyl alcohol to the sieved powder, mix evenly, and use 115MPa pressure to dry press into rectangular strips in a steel casting mold. At 1500 ° C, sintered in an air atmosphere for 10 h to...

Embodiment 2

[0029] The preparation method and preparation conditions of this embodiment and the above-mentioned embodiment 1 are the same, and its difference from embodiment 1 is that the citric acid-combustion synthesis method is used to synthesize Sr 2 Al x Mg 1-x MoO 6-δ (x=0.02) Dense sample. According to Sr 2 Al x Mg 1-x MoO 6-δ (x=0.02) stoichiometric ratio preparation, Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 O was dissolved in deionized water, respectively.

[0030] Using four-terminal lead method at 5%H 2 / Ar atmosphere, the reduction temperature is 1300 ° C, after reduction for 24 hours, the anode material Sr 2 Al x Mg 1-x MoO 6-δ (x=0.02) conductivity. The experimentally measured conductivity reaches 4.47S / cm at 800°C.

Embodiment 3

[0032] The preparation method and preparation conditions of this embodiment and the above-mentioned embodiment 1 are the same, and it is different from embodiment 1 in adopting citric acid-combustion synthesis method to synthesize Sr 2 Al x Mg 1-x MoO 6-δ (x=0.03) Dense sample. According to Sr 2 Al x Mg 1-x MoO 6-δ (x=0.03) stoichiometric ratio preparation, Sr(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 O was dissolved in deionized water, respectively.

[0033] Using four-terminal lead method at 5%H 2 / Ar atmosphere, the reduction temperature is 1300 ° C, after reduction for 24 hours, the anode material Sr 2 Al x Mg 1-x MoO 6-δ (x=0.03) conductivity. The experimentally measured conductivity reaches 4.82S / cm at 800°C.

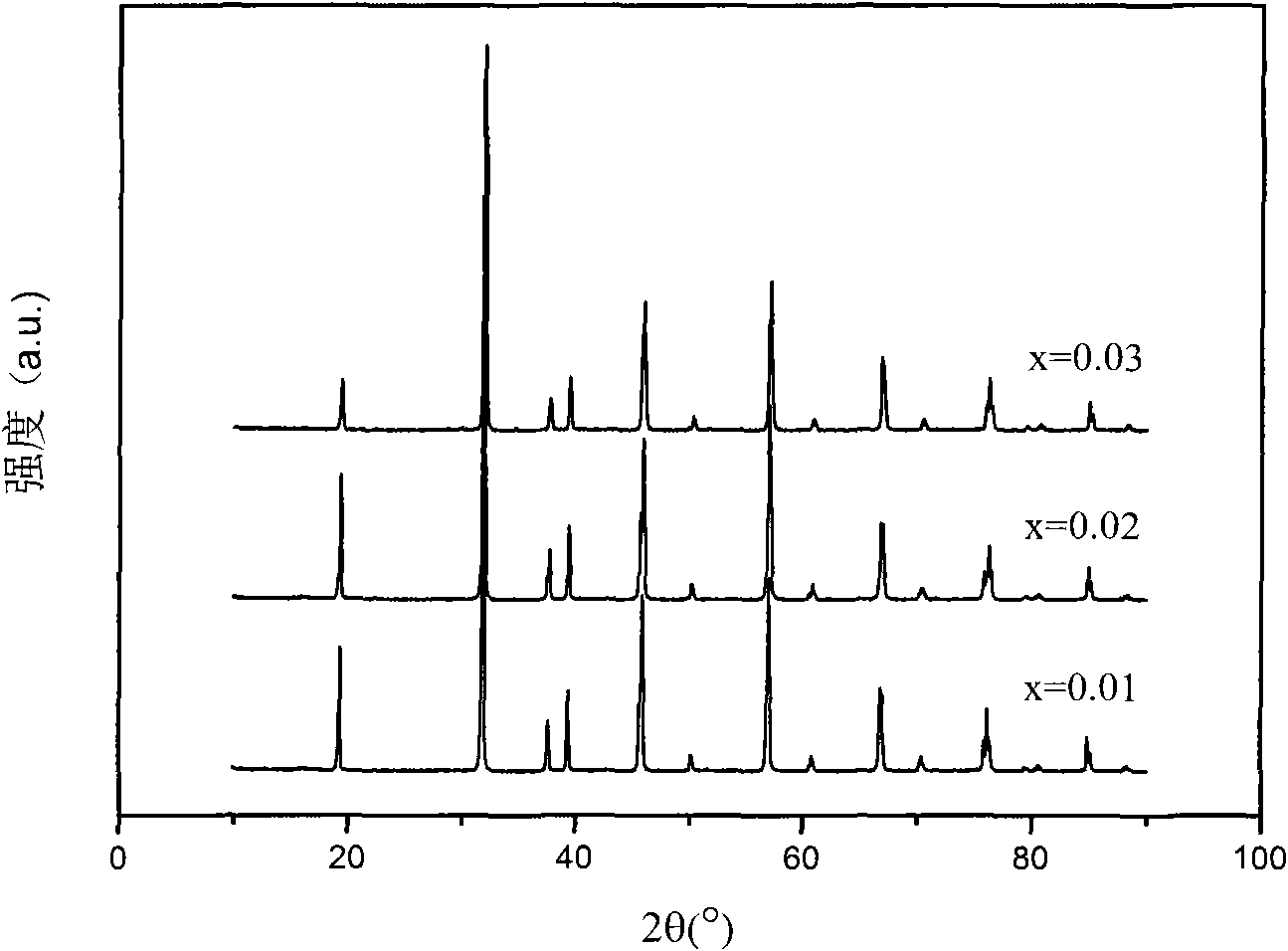

[0034] figure 1 The Sr synthesized by the citric acid-combustion synthesis method for the present invention 2 Al x Mg 1-x MoO 6-δ , x=0.01-0.03 XRD pattern of the powder, the synthesis temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com