Anti-explosion nickel battery and anti-explosion ball and preparation method thereof

A technology of explosion-proof balls and nickel batteries, which is applied in the manufacture of nickel batteries, alkaline batteries, alkaline batteries, etc. It can solve the problems of explosion-proof balls that are too late to deflate, battery internal pressure rises, and battery explosions to prevent pressure explosions and thermal explosions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

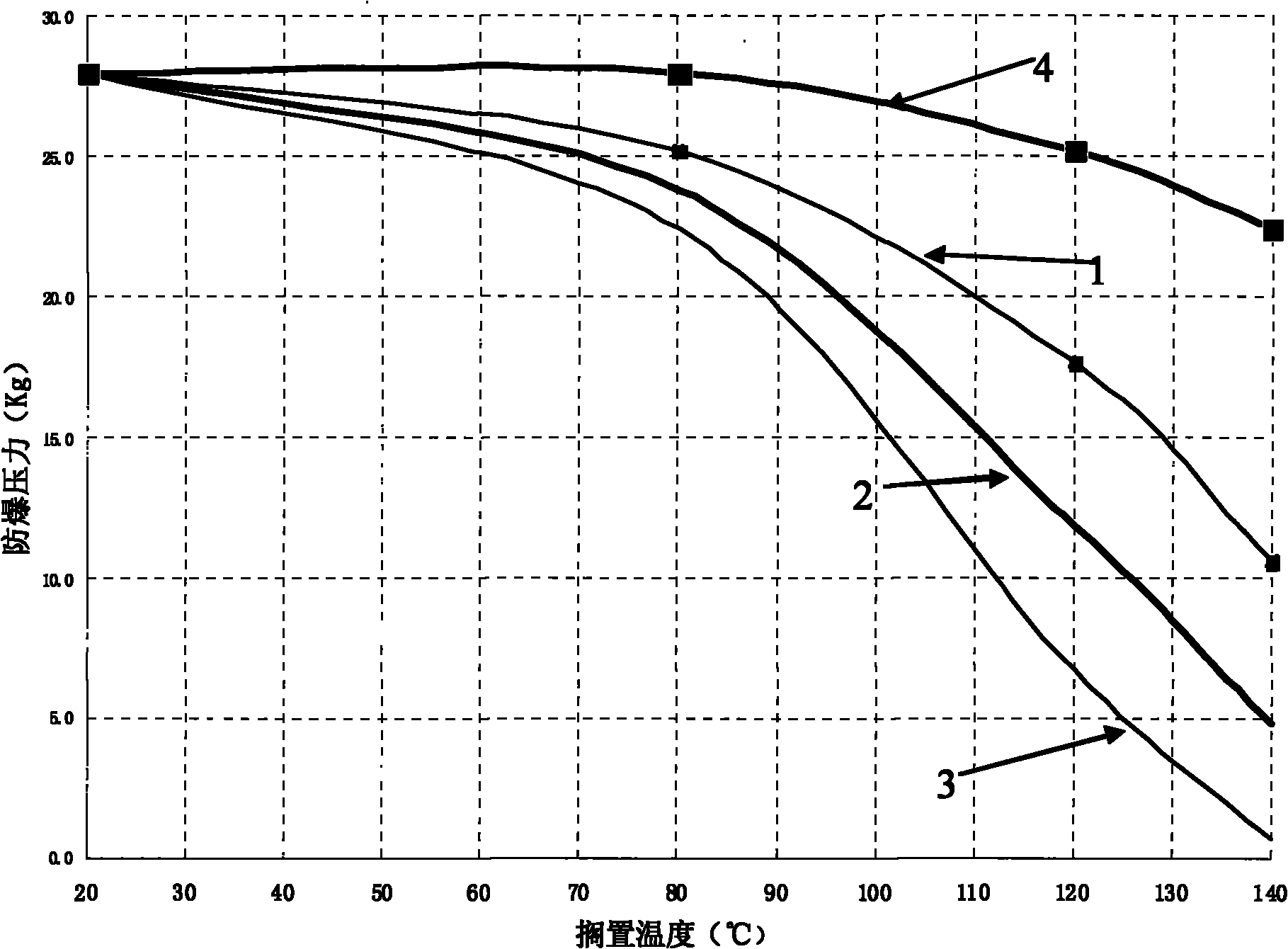

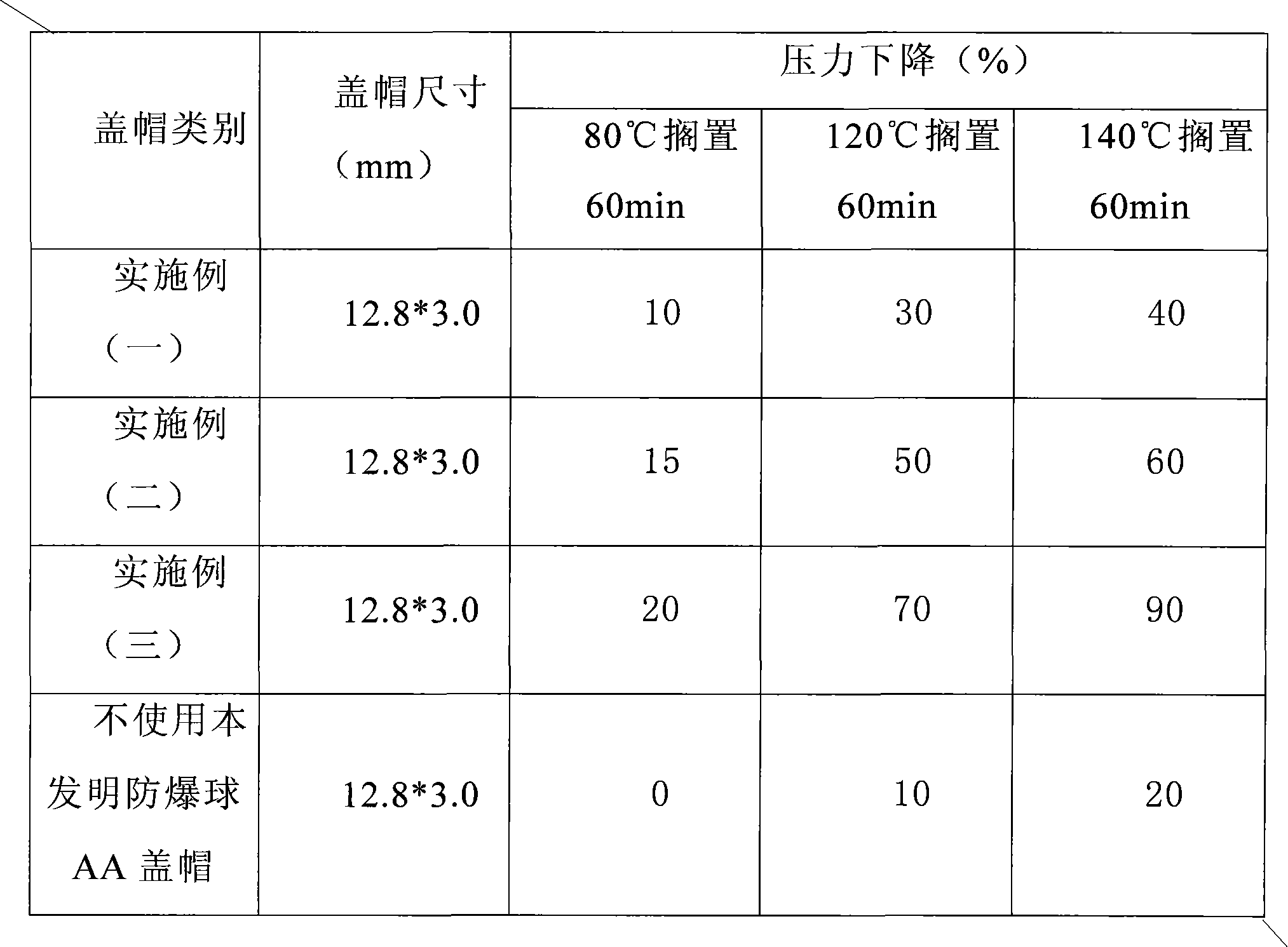

[0018] A method for manufacturing an explosion-proof ball for a cylindrical nickel-hydrogen battery. Firstly, EPDM rubber is weighed in proportion, and masticated at a temperature of 150°C. After adding carbon black and zinc dimethyl dithiocarbamate (PZ, the same below), the process of rolling, extrusion, vulcanization, molding and other processes is completed. Wherein the content of EPDM rubber is 86%, carbon black is 13.5%, PZ is 0.2%, sulfur (vulcanizing agent) is 0.3%, and the contents of the above components are percentages by weight. Match the prepared AA explosion-proof ball with cold-rolled carbon steel plate to make AA cap. Use the cap made by the present invention to compare the performance of the cap made without using the present invention.

Embodiment 2

[0020] A method for manufacturing an explosion-proof ball for a cylindrical nickel-hydrogen battery. Firstly, EPDM rubber is weighed in proportion, and masticated at a temperature of 180°C. After adding carbon black and PZ, kneading, calendering, extrusion, vulcanization, molding and other processes to complete the production. Wherein the content of EPDM rubber is 86%, carbon black is 13.5%, PZ is 0.2%, sulfur (vulcanizing agent) is 0.3%, and the contents of the above components are percentages by weight. Match the prepared AA explosion-proof ball with cold-rolled carbon steel plate to make AA cap. Use the cap made by the present invention to compare the performance of the cap made without using the present invention.

Embodiment 3

[0022] The invention discloses a manufacturing method of an explosion-proof ball for a cylindrical nickel-hydrogen battery. Firstly, EPDM rubber is weighed in proportion, and plasticized at a temperature of 200°C. After adding carbon black and PZ, kneading, calendering, extrusion, vulcanization, molding and other processes to complete the production. Wherein the content of EPDM rubber is 86%, carbon black is 13.5%, PZ is 0.2%, sulfur (vulcanizing agent) is 0.3%, and the contents of the above components are percentages by weight. Match the prepared AA explosion-proof ball with cold-rolled carbon steel plate to make AA cap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com