DHA fortified rice and preparation method thereof

A technology for rice and rice flour, applied in the field of DHA-enhanced rice and its preparation, can solve the problem of unsatisfied rice containing DHA nutrients and the like, and achieve the effects of high degree of industrial automation, convenient production and good storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

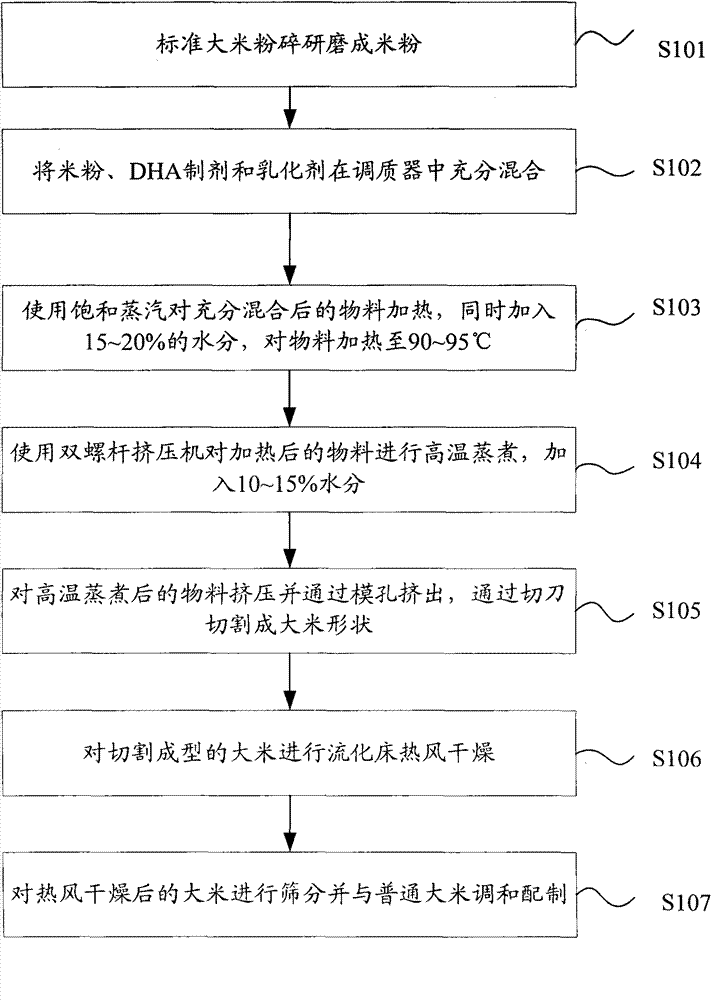

Method used

Image

Examples

preparation example Construction

[0031] According to the preparation method described in the preferred embodiment of the present invention, the sleeve temperature of the twin-screw extruder during high-temperature cooking is 40-80 degrees Celsius, the screw speed is 120-180 rpm, and the cutter speed is 800-1300 rpm.

[0032] S105: Extrude the material after high-temperature cooking and extrude it through the die hole, and cut it into a rice shape by a cutter;

[0033] In order to achieve the purpose of cutting rice grains of different sizes, the die hole of the extruder can be adjusted. The die hole is elliptical, with a major axis of 4-6 mm and a minor axis of 1.8-2.0 mm.

[0034] S106: Drying the cut and shaped rice with hot air in a fluidized bed.

[0035] The temperature of the fluidized bed hot air drying is 60-80 degrees Celsius, and the time lasts for 40-120 minutes.

[0036] S107: Sieve the hot-air dried rice and blend it with ordinary rice for preparation.

Embodiment 1

[0038] First, rice is pulverized into 80 mesh rice flour with a hammer mill, and the rice flour of weight ratio 62.0 and the powder of 5% DHA content of specific gravity 5.0 and the emulsifier (monoglyceride) of specific gravity 1.0 are accurately weighed, and these materials are Fully mixed in the conditioner to obtain mixture A;

[0039] Afterwards, add 135°C saturated steam to heat the mixture A, add water with a specific gravity of 22.0, mix thoroughly to make the temperature reach 90°C, and obtain material B.

[0040] Material B was extruded on a BCTG-60 twin-screw extruder under the following extrusion conditions: screw speed 140r / min, sleeve temperature 50°C, die plate outlet temperature 80°C, and water with a specific gravity of 10.

[0041] Material B is extruded through the die hole and cut into rice grains by the cutter. The long axis of the die hole is 4.8mm, the short axis is 1.5mm, and when the cutting knife speed is 750r / min, rice grains with a thickness of 1.7m...

Embodiment 2

[0048] Similar to Example 1, at first rice is ground into 80 mesh rice flour, after that, the rice flour of specific gravity 65.0 and specific gravity are the emulsifier (monoglyceride) of 15% DHA content of 2 and specific gravity 1.5, Fully mixed in the container to obtain mixture A;

[0049] Add 135°C saturated steam to heat the mixture A, add 19.5% water, mix thoroughly to make the temperature reach 92°C, and obtain material B.

[0050] The material B was extruded on a BCTG-60 twin-screw extruder, and the extrusion conditions were: screw speed 160r / min, sleeve temperature 55°C, die plate outlet temperature 95°C, and water addition 12.

[0051] Material B is extruded through the die hole and cut into rice grains by the cutter. When the long axis of the die hole is 6.8mm, the short axis is 1.3mm, and the cutting knife speed is 850r / min, the rice grains with a thickness of 1.5mm can be cut. Similar to regular long grain rice.

[0052]The cut and shaped rice grains are sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com