Conductive nylon 66 material and preparation method thereof

A nylon, 6680%-95% technology, applied in the field of conductive nylon materials and its preparation, can solve the problems of high volume resistivity and limited application, and achieve the effects of excellent electrical conductivity, convenient operation, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

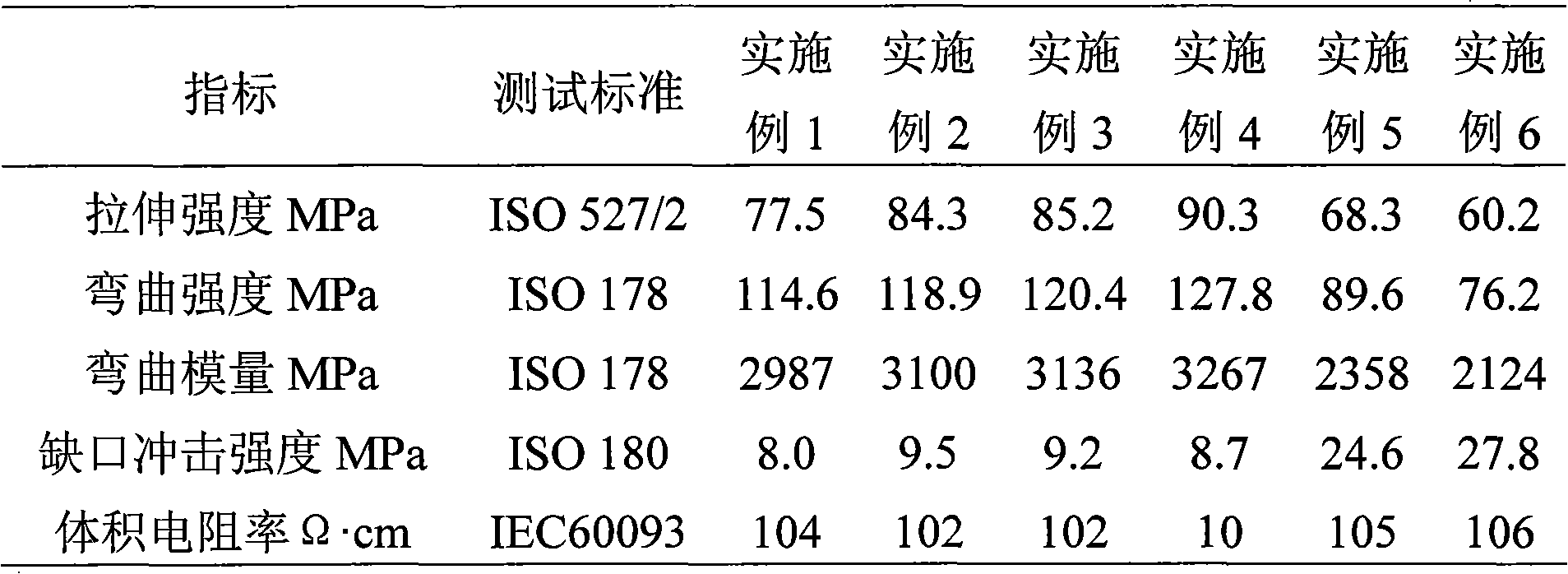

Examples

Embodiment 1

[0016] A conductive nylon 66, the weight percentage of each component is: nylon 6694.46%, carbon nanotube 1.05%, compatible toughening agent 1.95%, nano-montmorillonite 1.04%, antioxidant 0.5%, nucleating agent 0.5% %, lubricant 0.5%.

[0017] The nylon 66 material viscosity is a polyamide resin (Germany BASF Co., Ltd.) of 2.8. The carbon nanotubes are multi-walled carbon nanotubes with an average outer diameter of 11 nm, an average length of 11 μm, and a purity greater than 95%. The particle size of the nano-montmorillonite is 80nm. The compatible toughening agent is polyethylene-octene copolymer grafted with maleic anhydride, and the grafting rate is greater than or equal to 0.9% (Nanjing Youyou Auxiliary Chemical Co., Ltd.). The antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine (Nanjing Milan Chemical Co., Ltd.). The nucleating agent is talcum powder with a particle size of about 1250 mesh (Guilin Tiancheng Co., Ltd.). The lubr...

Embodiment 2

[0021] A conductive nylon 66, the weight percent of each component is: nylon 6688.6%, carbon nanotube 3%, compatible toughening agent 4.5%, nanometer montmorillonite 2.4%, antioxidant 0.5%, nucleating agent 0.5% %, lubricant 0.5%.

[0022] The nylon 66 material viscosity is a polyamide resin (Germany BASF Co., Ltd.) of 2.8. The carbon nanotubes are multi-walled carbon nanotubes with an average outer diameter of 11 nm, an average length of 11 μm, and a purity greater than 95%. The particle size of the nano-montmorillonite is 80nm. The compatible toughening agent is polypropylene grafted with maleic anhydride, and the grafting rate is greater than or equal to 0.9% (Nanjing Youyou Auxiliary Chemical Co., Ltd.). The antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine (Nanjing Milan Chemical Co., Ltd.). The nucleating agent is talcum powder with a particle size of about 1250 mesh (Guilin Tiancheng Co., Ltd.). The lubricant is ethylene ac...

Embodiment 3

[0026] A conductive nylon 66, the weight percent of its components is: nylon 6684%, carbon nanotube 5%, compatible toughening agent 4.5%, nano-montmorillonite 5%, antioxidant 0.5%, nucleating agent 0.5% %, lubricant 0.5%.

[0027] The nylon 66 material viscosity is a polyamide resin (Germany BASF Co., Ltd.) of 2.8. The carbon nanotubes are multi-walled carbon nanotubes with an average outer diameter of 11 nm, an average length of 11 μm, and a purity greater than 95%. The particle size of the nano-montmorillonite is 80nm. The compatible toughening agent is polypropylene grafted with maleic anhydride, and the grafting rate is greater than or equal to 0.9% (Nanjing Youyou Auxiliary Chemical Co., Ltd.). The antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine (Nanjing Milan Chemical Co., Ltd.). The nucleating agent is talcum powder with a particle size of about 1250 mesh (Guilin Tiancheng Co., Ltd.). The lubricant is ethylene acrylic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com