Special pressed carbon block for blast-furnace ironmaking as well as manufacturing and using methods thereof

A blast furnace ironmaking and manufacturing method technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of wear resistance, crush resistance and strength, low uniformity of internal structure, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation of the present invention can be illustrated by examples. Since the pressed carbon block and its manufacturing method have a strong correlation, a joint description is made by way of a comprehensive embodiment.

[0069] Comprehensive Example 1

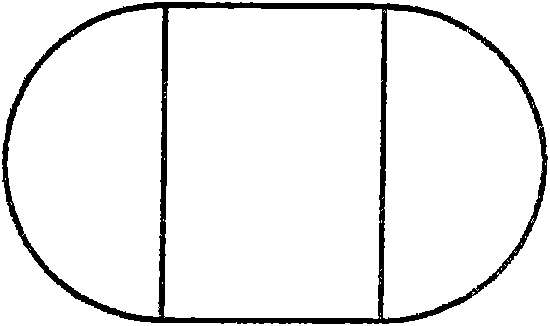

[0070] First determine the pressed carbon block. In this comprehensive embodiment, the selection of the pressed carbon block is as follows: Figure 15 The shape shown, and determine its large cylinder diameter is 65mm, the total length is 70mm, the number of grooves is 6, the groove width at the outer circle is about 14mm, the groove depth is about 12mm, and the arc diameter of the groove bottom is 9mm , the diameter of the small cylinder at both ends is 40mm, and the axial length is 12mm. At the same time, in order to prevent the sharp corners from being brittle and form carbon powder; also to prevent thermal stress concentration and fracture at the sharp corners of the bottom of the angular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com